Bolt pre-tightening force testing device and control method thereof

A technology of bolt pre-tightening force and control method, which is applied in the measurement of hydraulic/pneumatic force, and the measurement of torque/torsion force during tightening, which can solve the problems of inaccurate test results, increase test costs, and low work efficiency, and reduce The cost of experimental equipment, the effect of improving the accuracy of the test, and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

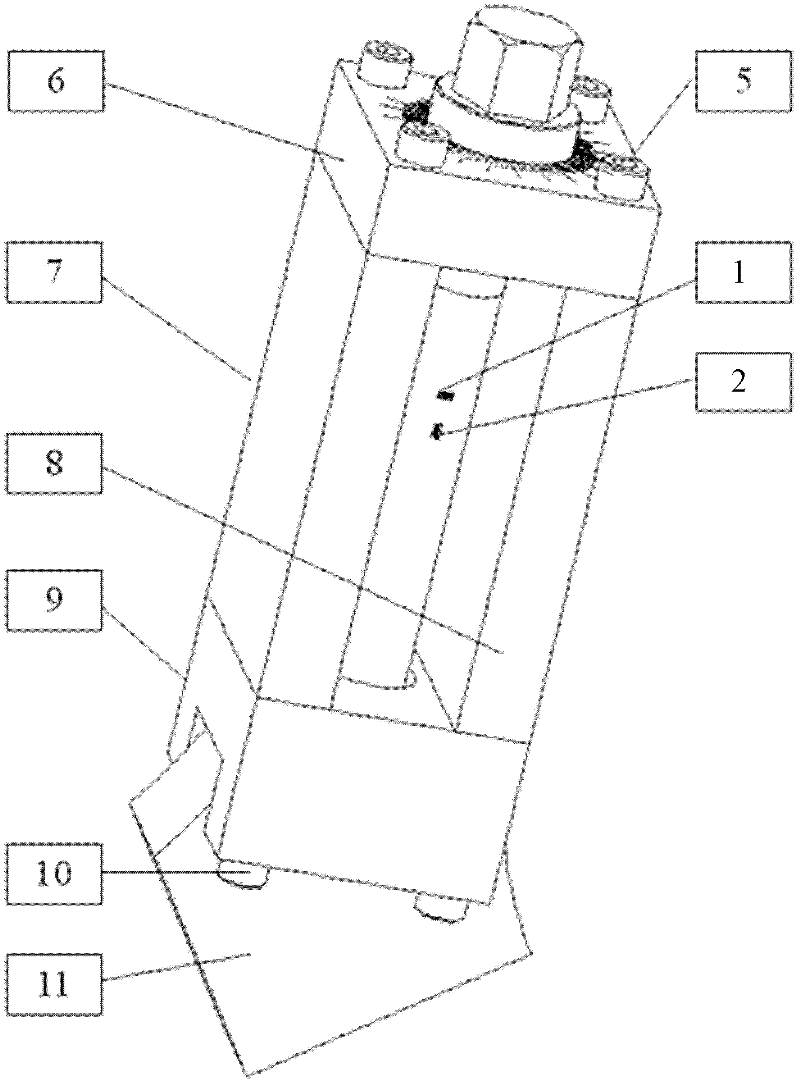

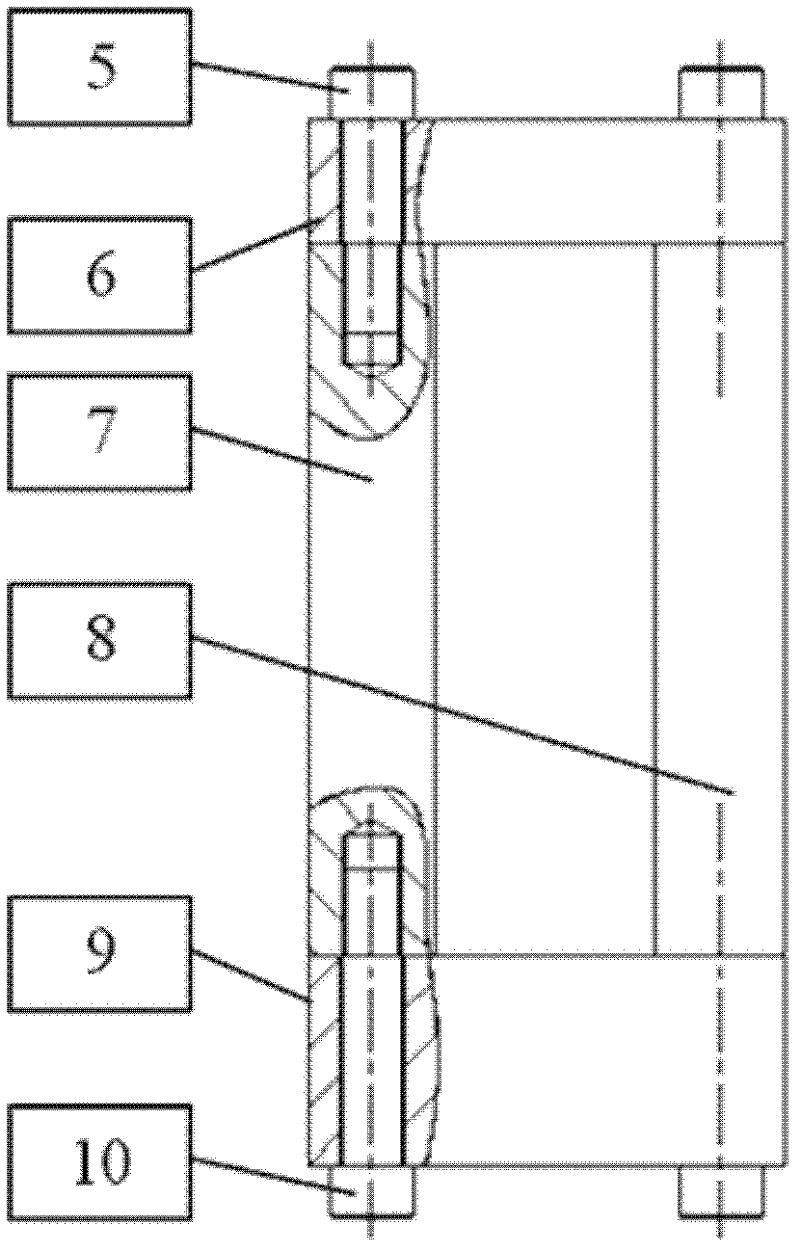

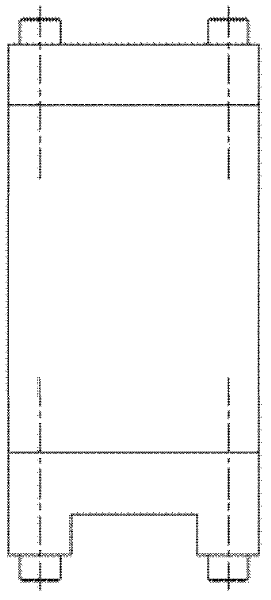

[0037] In order to realize the indirect measurement of the relationship between the bolt pre-tightening angle and the pre-tightening force, so as to meet the requirements of testing the bolt pre-tightening force, the method is simple and reduces the cost of experimental equipment, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the embodiment of the present invention provides a device for testing the pretightening force of bolts, see the following description for details:

[0038] A device for testing the pre-tightening force of bolts, comprising: a first connecting plate 7, a second connecting plate 8 arranged parallel to the first connecting plate 7, and a connection between the top of the first connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com