Horizontal shear guided wave thickness measuring method based on electromagnetic ultrasonic transducer

A horizontal shear, electromagnetic ultrasonic technology, applied in the use of ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the problem of thickness measurement of difficult metal specimens, and achieve low acoustic attenuation, high detection efficiency, multi-mode and Simple effect of dispersion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

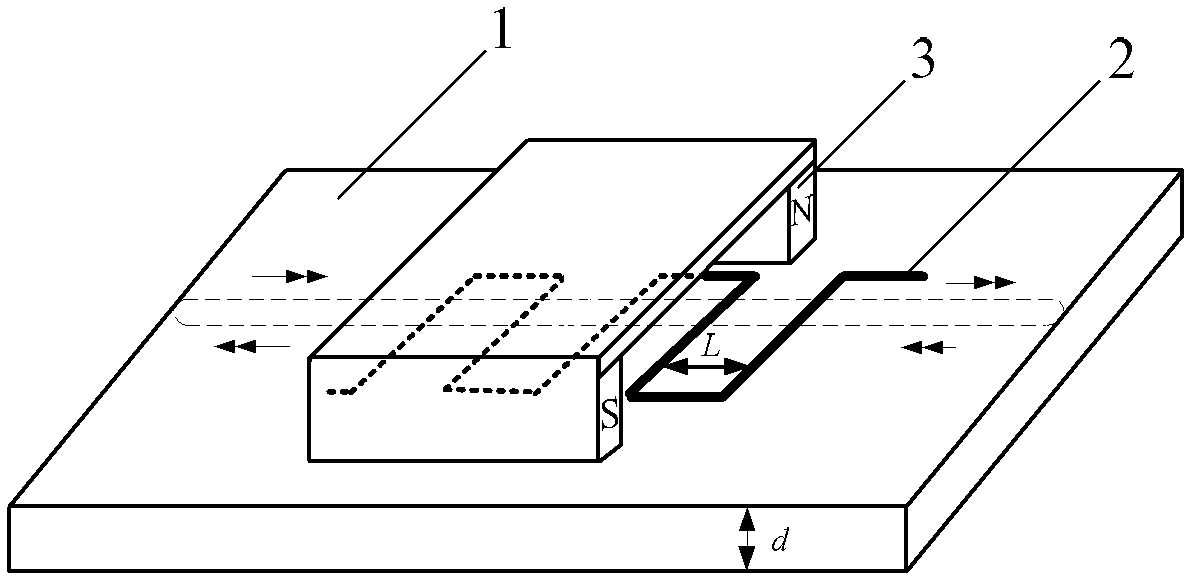

[0018] Specific implementation mode one: the horizontal shear guided wave thickness measurement method based on the electromagnetic ultrasonic transducer described in this implementation mode is realized by the following steps:

[0019] Step 1: Calculate the excitation equation of the horizontal shear guided wave in the test piece 1:

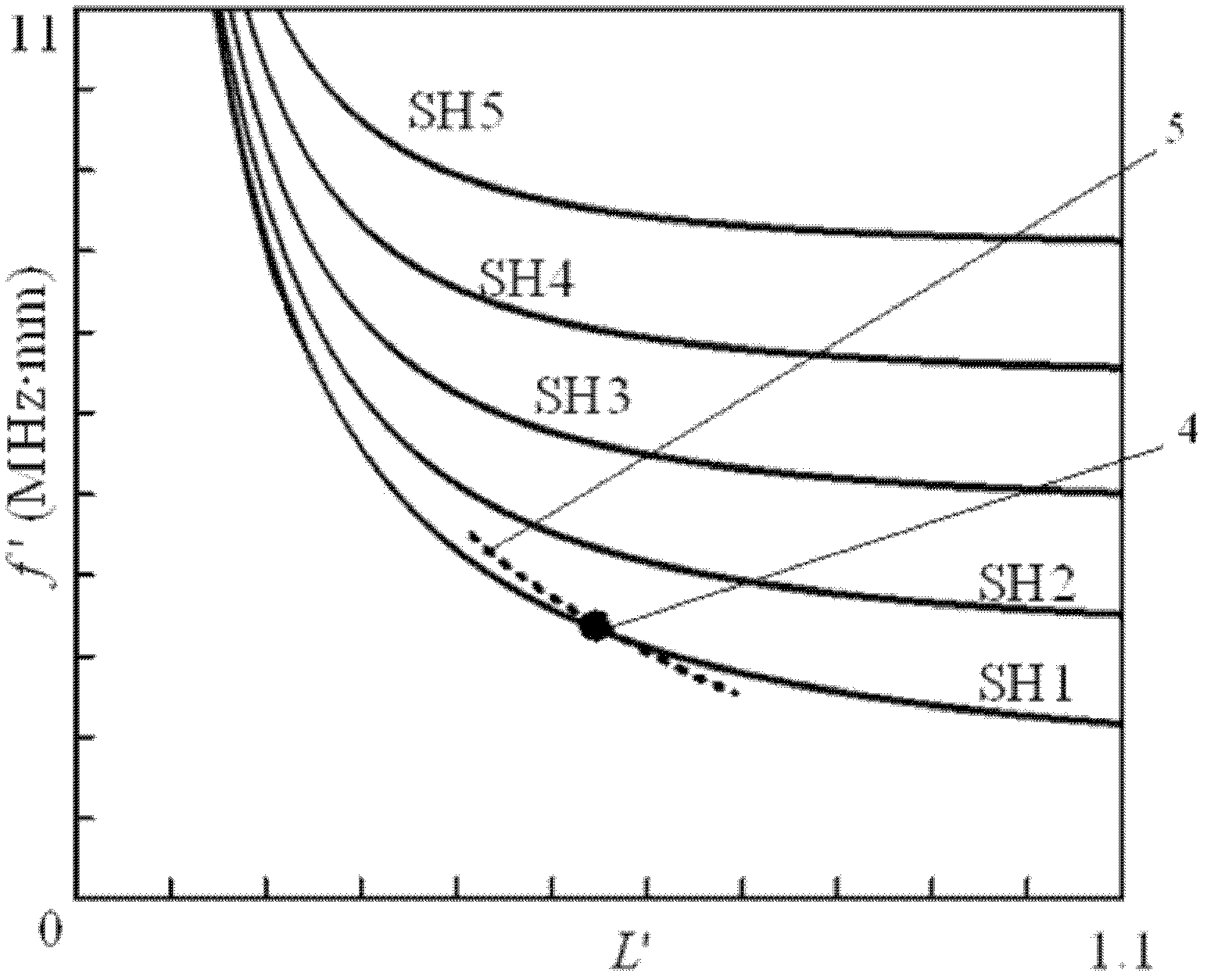

[0020] 4 f ′ 2 c s 2 - 1 L ′ 2 = n 2 , n ∈ { 1,2,3 . . . } Formula 1

[0021] In Equation 1, the parameter c s Indicates the shear wave velocity of the test piece 1; the parameter L' indicates the ratio ...

specific Embodiment approach 2

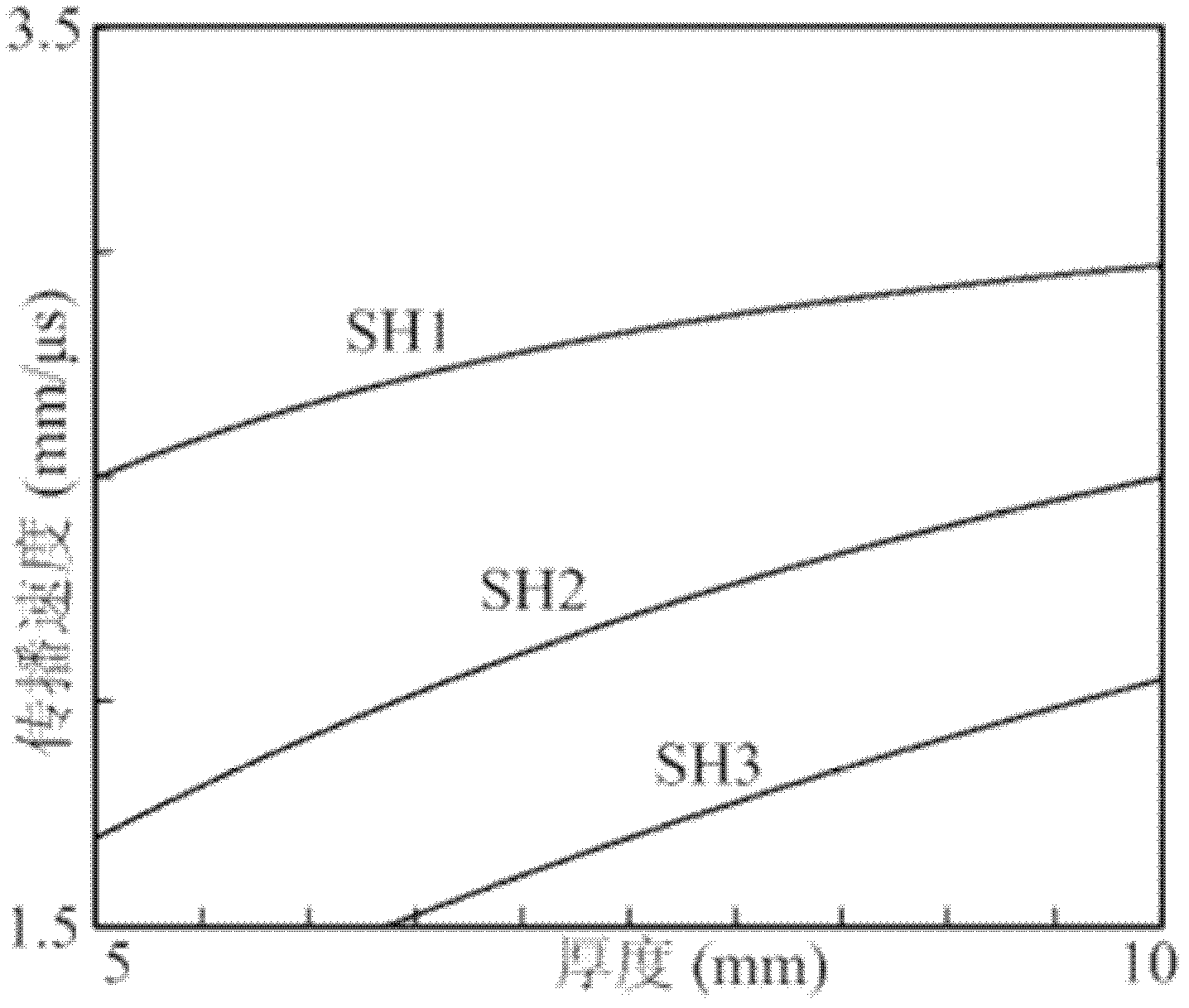

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the position coefficient γ of the SHn mode of the reference specimen calculated in step five is obtained by formula 3:

[0031] γ = ( c max - c g ) · ( c max · c g + 1 ) ( c g - c min ) · ( ...

specific Embodiment approach 3

[0032] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 6, according to the position coefficient γ described in step 5, the propagation velocity c of the horizontal shear guided wave in the SHn mode in the test piece 1 is obtained 1 The solution equation in uses Equation 4:

[0033] ( c max 1 - c 1 ) · ( c max 1 · c 1 + 1 ) ( c 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com