Open-closed system station subway platform ventilation and smoke exhaust method

A subway platform, open and close technology, applied in cleaning methods and appliances, space heating and ventilation, chemical instruments and methods, etc., can solve the problems of increased height, large cross-sectional area, hidden dangers of air duct safety, etc., and achieve low cost reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

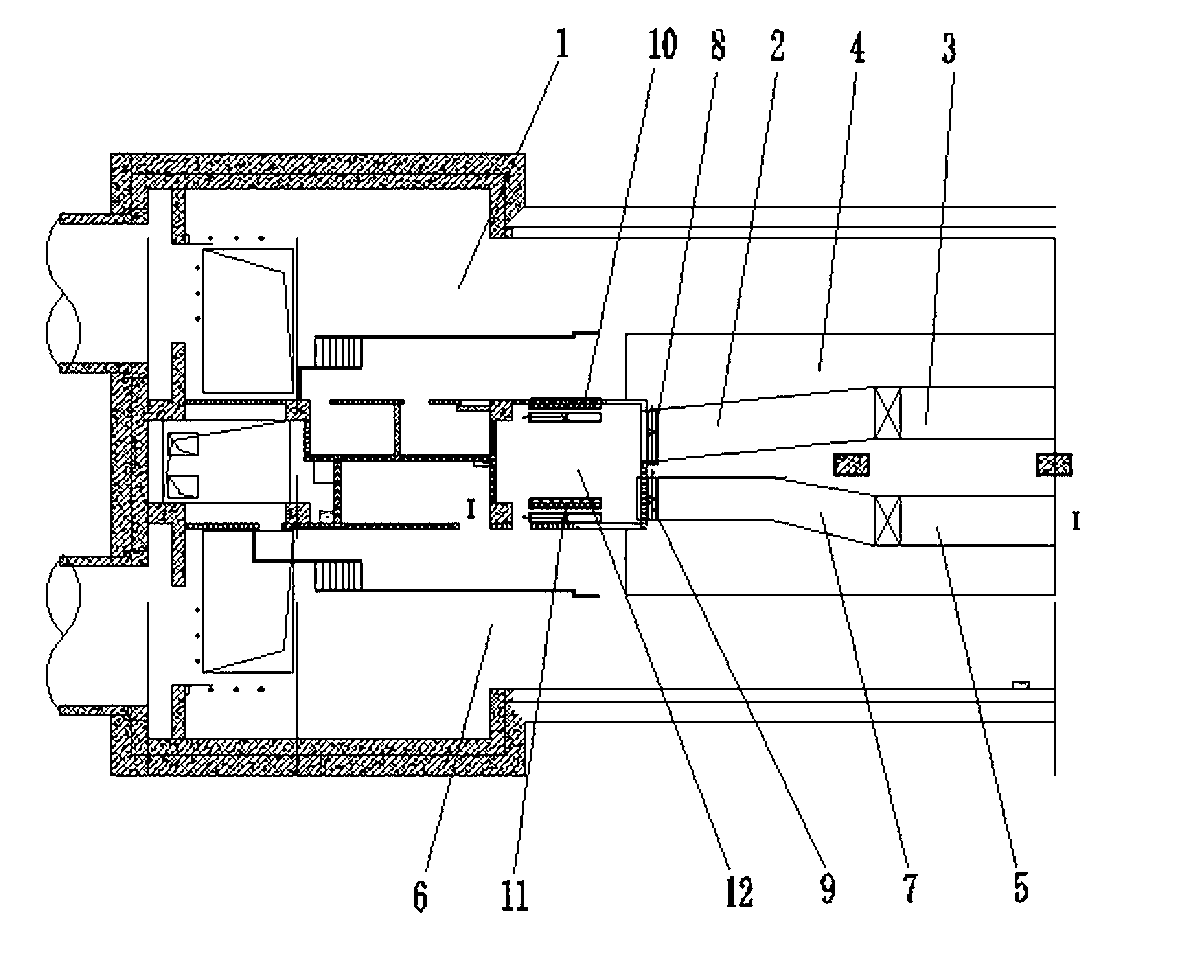

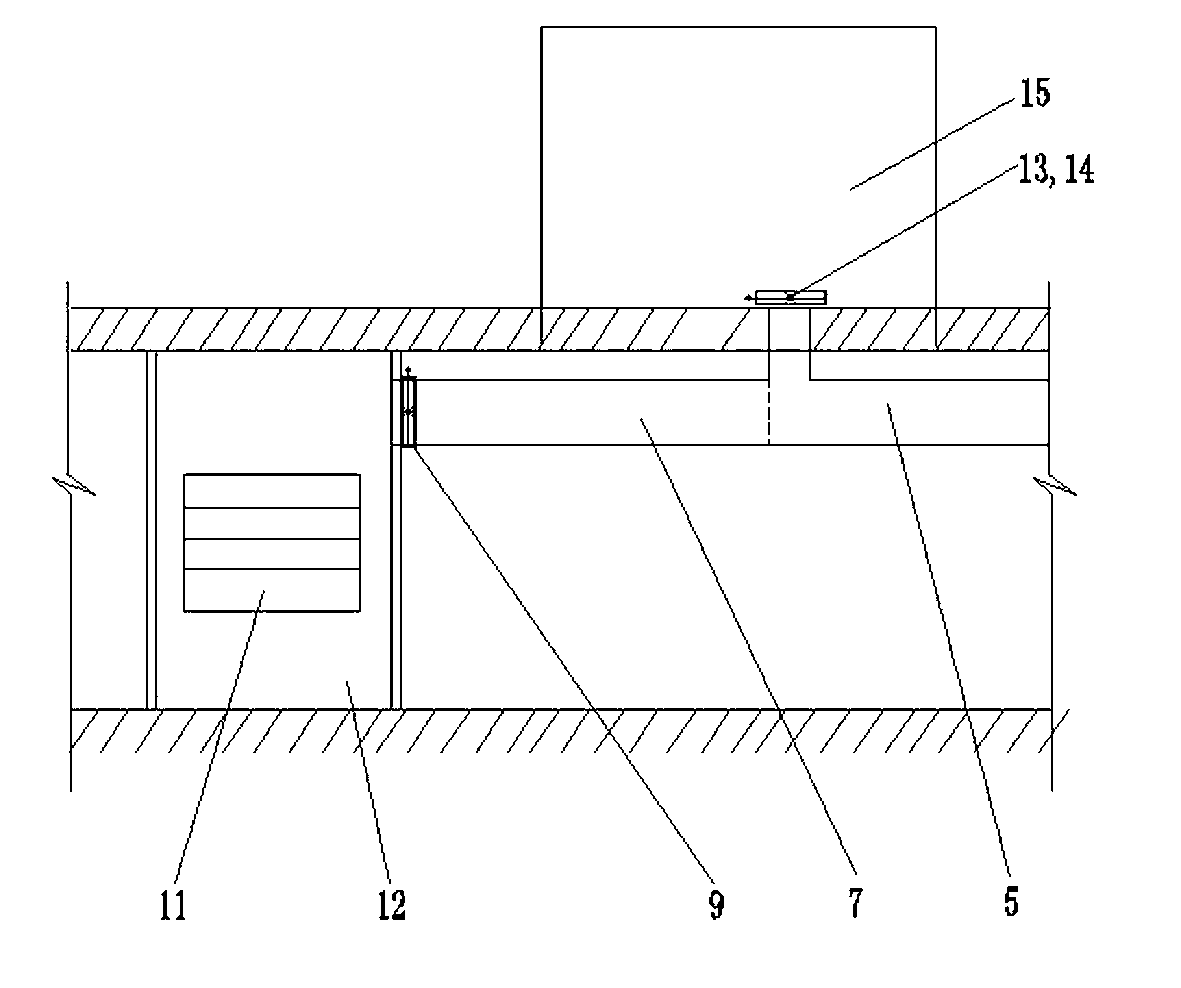

[0013] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

[0014] Such as Figure 1~2 As shown, the marks in the figure are: rail area 1, smoke exhaust pipe 2, air supply pipe 3, platform waiting area 4, air supply pipe 5, rail area 6, smoke exhaust pipe 7, damper 8, damper 9, Concentrated air return port 10, centralized air return port 11, air exhaust chamber 12, air valve 13, air valve 14, air supply chamber 15.

[0015] Example: such as figure 1 , 2 As shown, the track area 1 and the track area 6 are the track areas of the up and down subway trains, respectively located on both sides of the platform waiting area 4, and the exhaust air chamber 12 is located on one side of the platform waiting area 4. The top of 4 in the platform waiting area is provided with air supply pipe 3 and air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com