Loading method of reinforced welding nets by containers

A technology of welded steel mesh and container, applied in packaging, transportation and packaging, containers with multiple items, etc., can solve problems affecting product sales, transportation, etc., to ensure product transportation quality, reduce labor intensity, and high innovation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0019] A container loading method for welded steel mesh, the innovation is that: the container loading method for welded steel mesh includes the following steps:

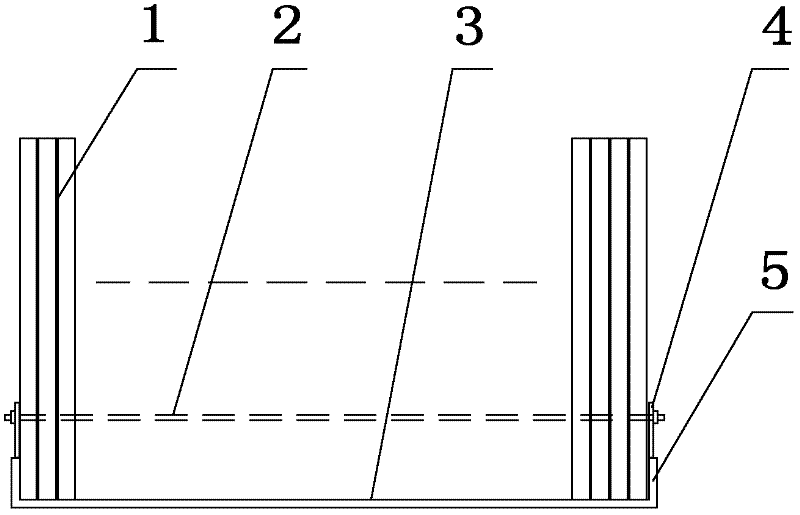

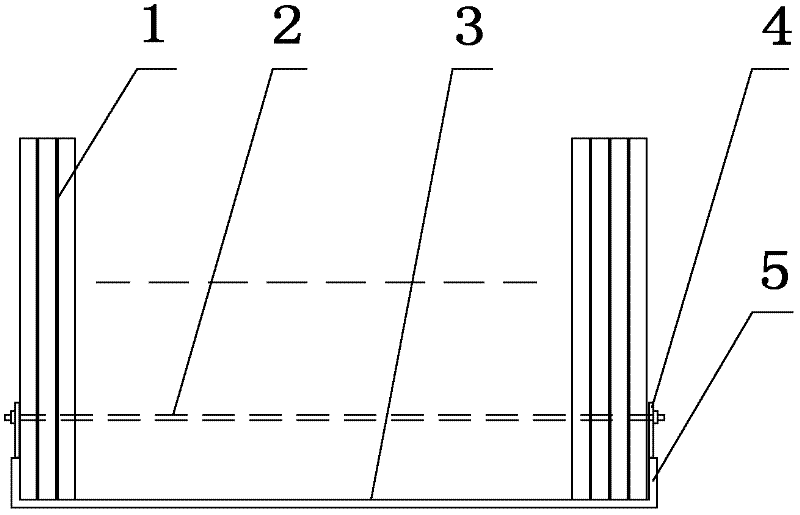

[0020] (1) Bundling and packaging of welded steel mesh: place 100-150 welded steel mesh 1 vertically side by side on a grooved bottom bracket 3, and install a A group of longitudinal fixing frames 4, a group of horizontal fixing rods 2 are installed at intervals in the mesh of the welded steel mesh, and the fixing frames fixed on the grooved bottom bracket are fixed with the two ends of the corresponding horizontal fixing rods to form a welded steel mesh bundle;

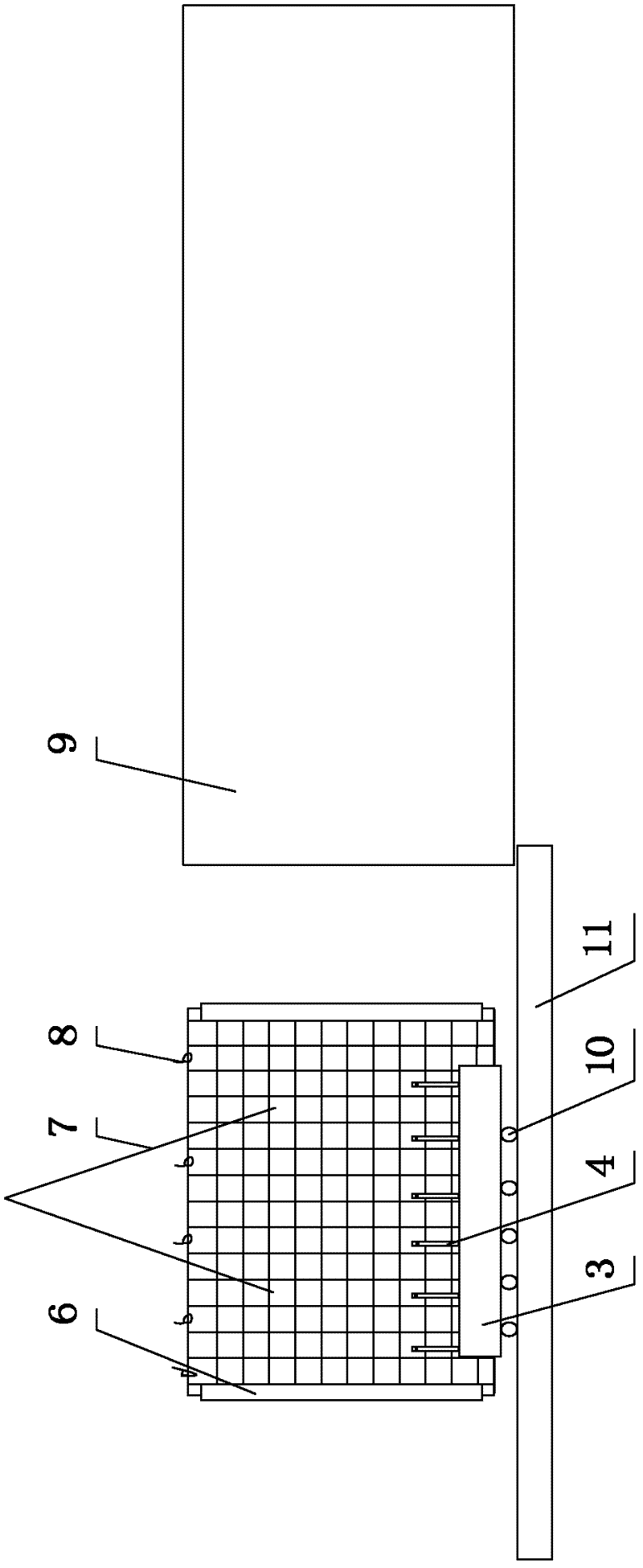

[0021] (2) Packing of welded steel mesh bundles: Put the lifting belt 7 on the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com