Automatic leakproof pressure gauge seat

A pressure gauge, automatic technology, applied in the direction of measuring fluid pressure, measuring devices, instruments, etc., can solve the problems of secondary injury accidents, waste of resources, pollution of the environment, etc., to prevent combustion or explosion accidents, avoid environmental pollution, convenient Remove the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

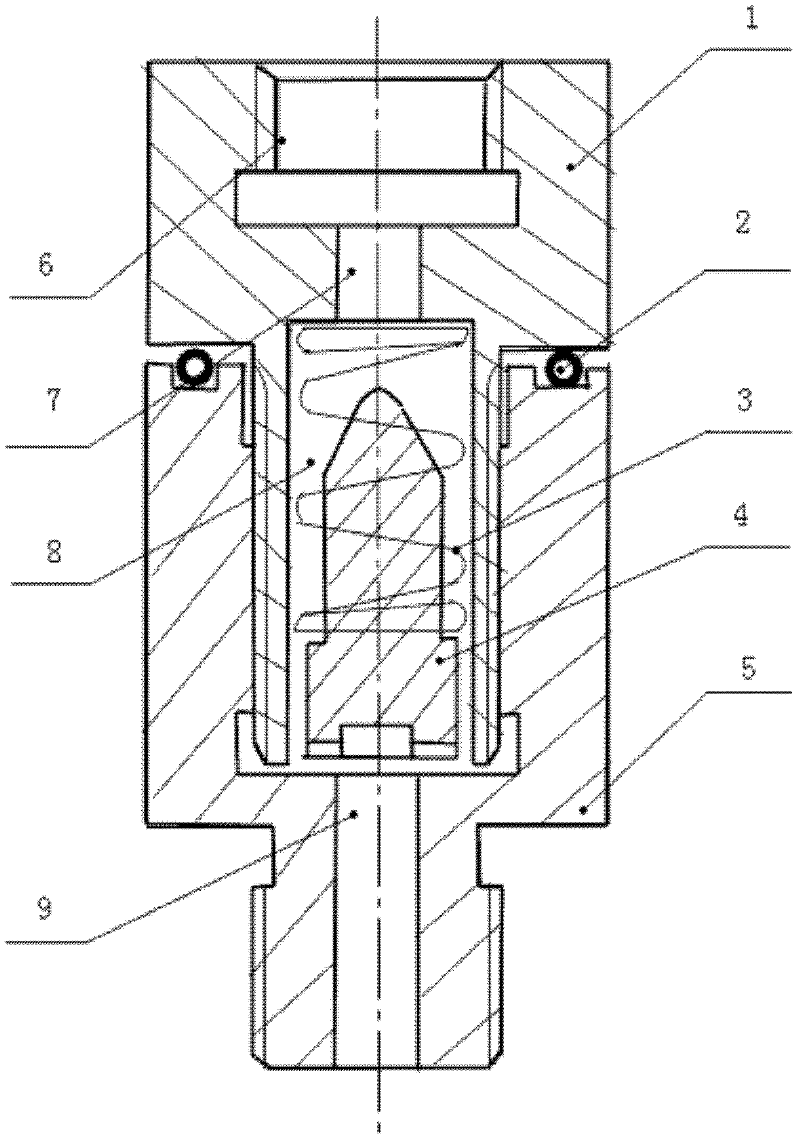

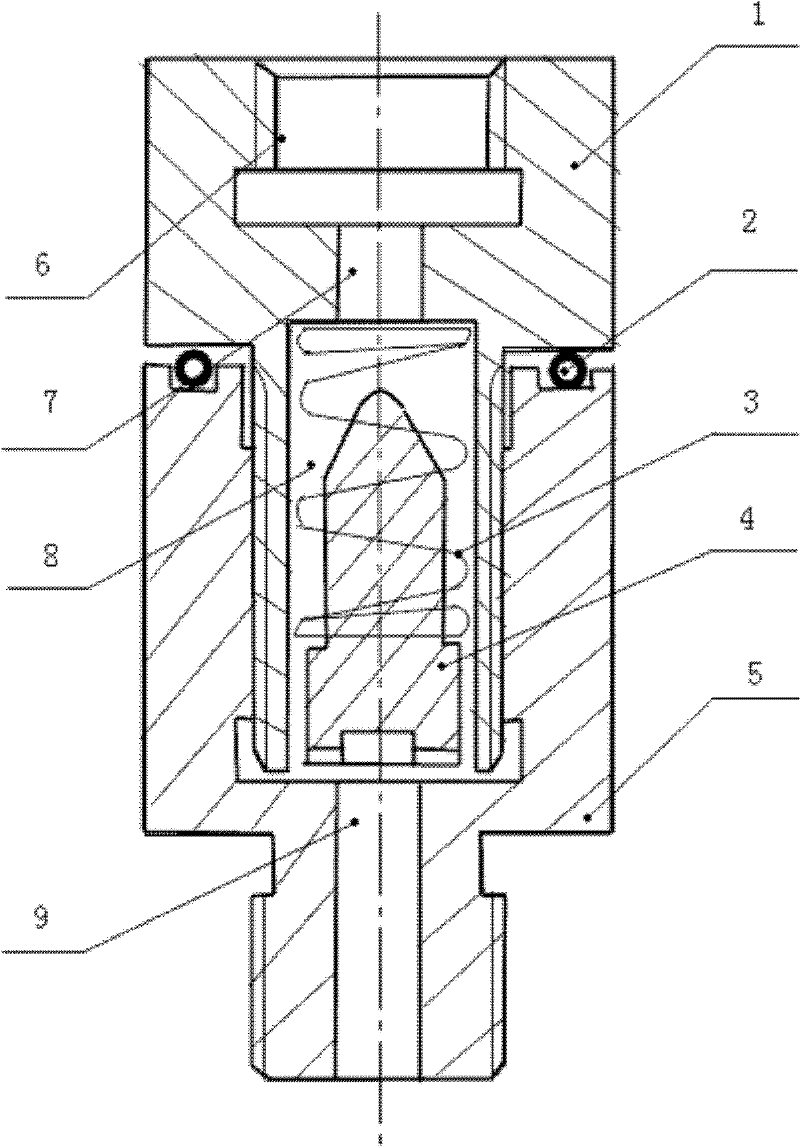

[0013] Automatic bleed-off pressure gauge seats, such as figure 1 As shown, it includes a seat body composed of an upper shell 1 and a lower shell 5, a pressure spring 3, and a sealing float 4. The seat body is transparent up and down, and a central chamber 8 is provided in the middle of the seat body, and a sealing float is arranged in the central chamber 8. 4. The sealing float 4 adopts a solid structure; the top of the central chamber 8 is provided with an outlet channel 7, the bottom end is provided with an inlet channel 9, and the top of the outlet channel 7 is provided with a seat groove 6 for installing a pressure gauge; the sealing float 4 has three sections Type structure, the top of which is conical, and the bottom of the conical structure is a stepped columnar structure; the inner diameter of the outlet channel 7 is smaller than the outer diameter of the widest part of the sealing float 4 cone; the outer side of the sealing float 4 is covered with a pressure spring 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com