Prefabricated combined beam and column node member

A beam-column joint and component technology, applied in the field of new stress-bearing components and cast-in-place reinforced concrete joints, can solve the problems of lack of support and positioning of the steel bar head, the quality of the welding point cannot be guaranteed, and the shape of the steel bar end is irregular, so as to solve the problem of the steel bar head. The effect of dense mesh, ensuring rigidity and welding quality, improving stability and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

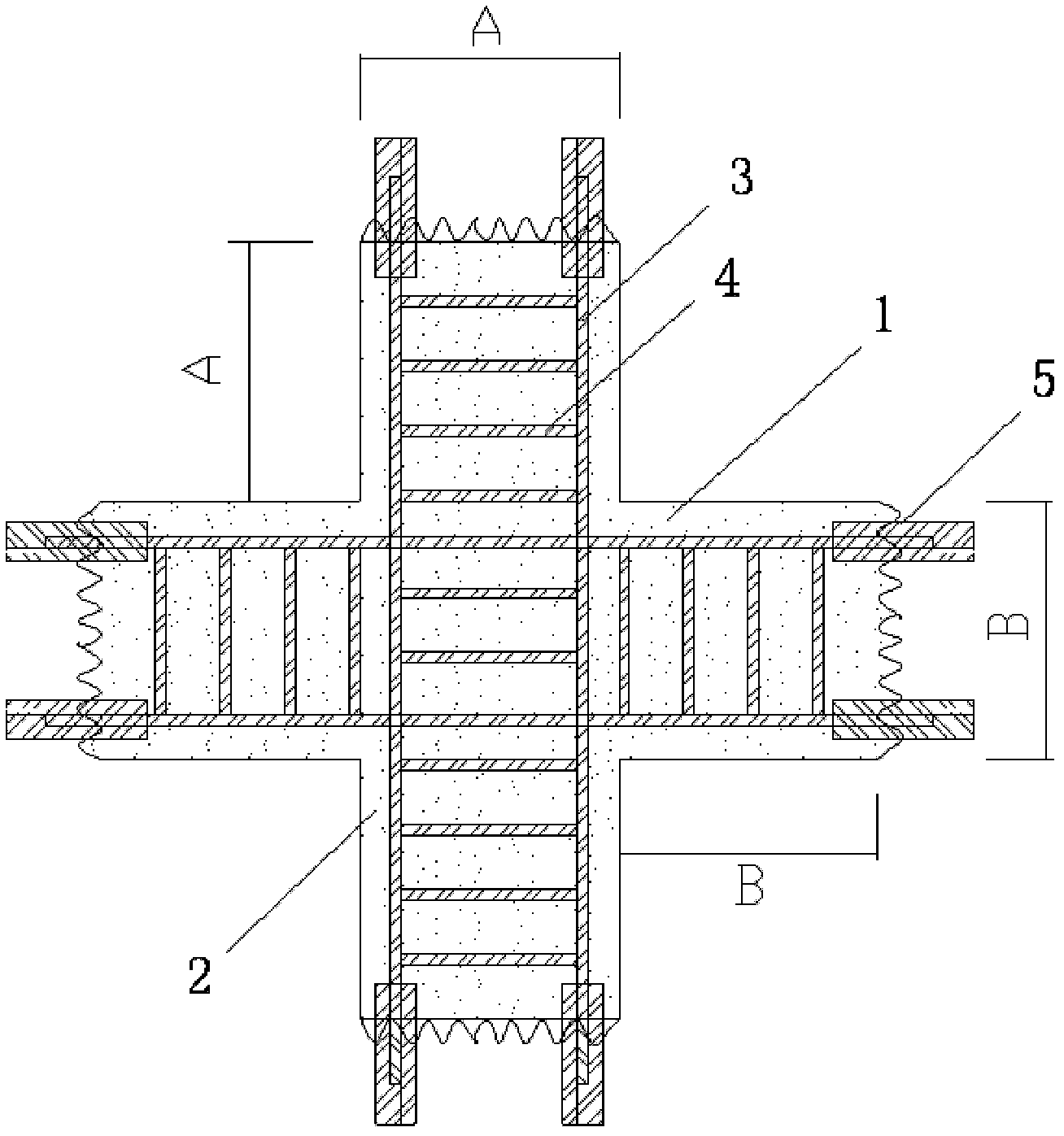

[0029] The prefabricated composite beam-column node component of the present invention includes intersecting beams 1 and columns 2, the beams 1 and columns 2 are composed of ECC materials, longitudinal bars 3 and stirrups 4, and the cross beams 1 and columns 2 overlap each other in a rectangular shape The transverse width of the area is A, and the longitudinal height is B; the transverse width of the beam 1 is 2B+A, and the longitudinal height is B, and the longitudinal rib 3 runs through the entire length of the beam 1 and protrudes from the two beam ends by 10cm to 15cm; the column The longitudinal height of 2 is 2A+B, and the longitudinal rib 3 runs through the entire length of the column 2 and protrudes from the two column ends by 10cm to 15cm.

[0030] In the present invention, the ends of the crossbeam 1 and the column 2 are all fixed with angle irons 5, and the angle irons 5 are welded with the steel bar 3, and the lengths of the angle irons 5 extending into the crossbea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com