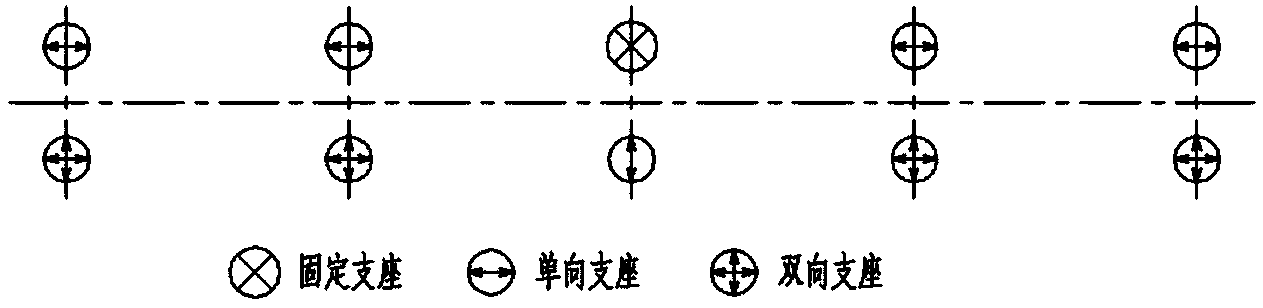

Arrangement method of supports of continuous box girder bridge

A technology of bearing and plane layout, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of reducing the thrust stiffness of bridge piers, and achieve the effect of increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

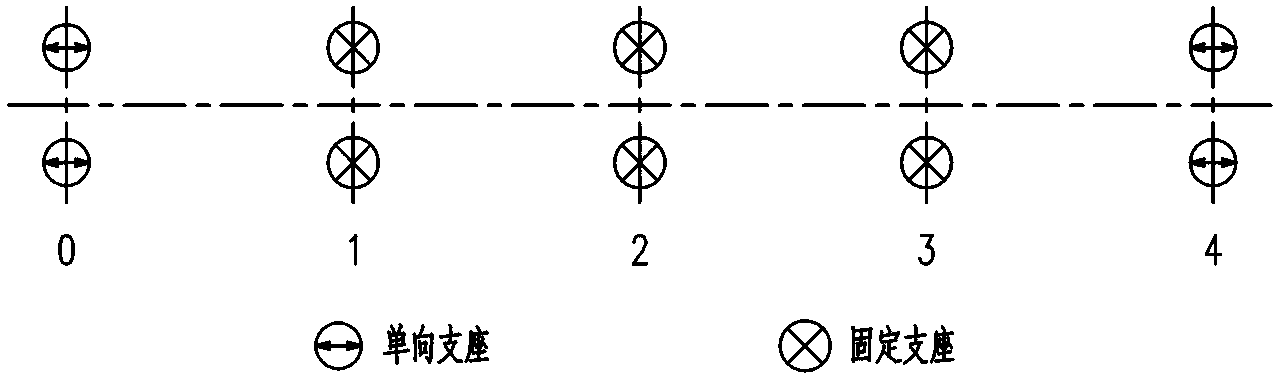

Embodiment 1

[0040] Example 1 The Mangshan interchange E-ramp bridge in the Yongcheng section of the Jining-Qimen Expressway is a 4-16 continuous box girder bridge with a width of 10.5m and piled piers. The heights of the three middle piers are 8.5m and 9m respectively. , 9.5m, and column diameter is 1.3m. The dead-load support reaction forces of piers No. 0 to No. 4 in the calculation book are 1619kN, 4395kN, 3937kN, 4875kN, and 1893kN respectively.

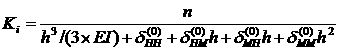

[0041] (1) The thrust stiffness of each pier

[0042] Calculation according to Appendix P of "Code for Design of Highway Bridge and Culvert Foundation and Foundation" (JTG D63-2007):

[0043] EI=3.1404×10 6 kN·m 2

[0044] =1.0543×10 -5 m

[0045] =2.2313×10 -6 rad

[0046] =2.2313×10 -6 m

[0047] =7.6434×10 -7 rad

[0048] n=2

[0049]

[0050]

[0051] =1.44×10 4 kN / m

[0052]

[0053] =1.27×10 4 kN / m

[0054]

[0055] =1.13×10 4 kN / m

[0056] (2) Calculate the fixed point S.P. (Stagnant Point) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com