Preparation method of performing body with extendable cross section dimension

A cross-sectional size and preforming technology, which is applied in the direction of braids, textiles and papermaking, can solve problems such as equipment capacity limitations, achieve yarn integrity, and improve research and application levels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

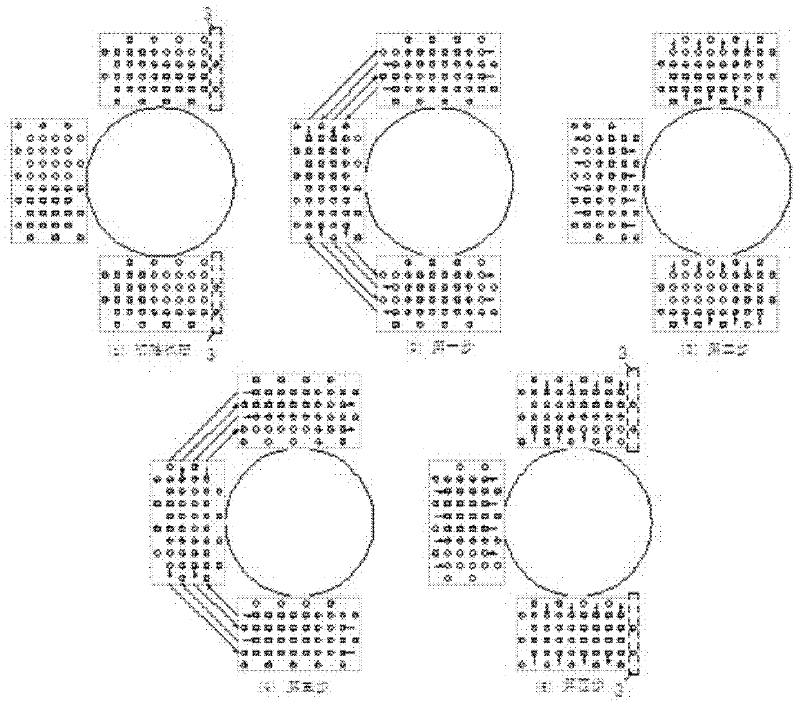

[0066] Two-ply T300 carbon fiber 3K was used to prepare a three-dimensional, four-directional, non-closed cubic preform with a hollow bottom of the core mold by the method of section size expansion. Dimensions of preform: 217×72×155mm 3 (a×b×c), wall thickness δ is 5mm, fiber volume content V f 50%, the size of the lined mandrel: 106×62×150mm 3 . Its weaving method is as follows:

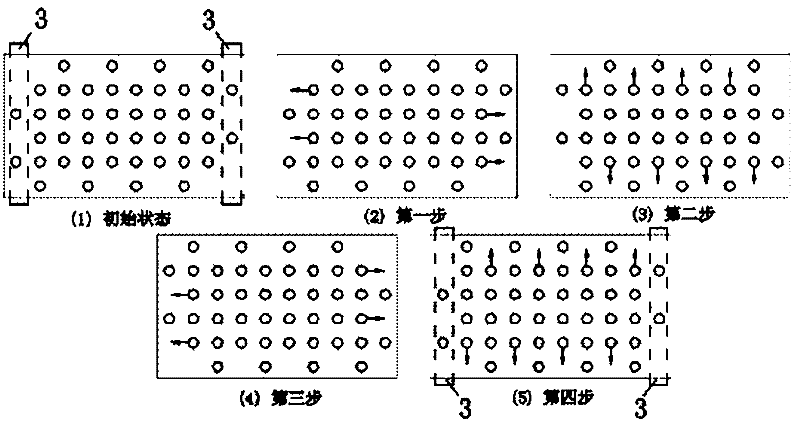

[0067] (1) Design of weaving process parameters: Design the weaving process parameters according to the external dimensions of the preform and the fiber volume content, which is a technology well known to those skilled in the art, and the total number of columns of the mother yarn determined by the design is 324 columns (corresponding to Figure 2-3 middle a A It is 102 columns, b is 60 columns), the number of rows is 9, the female node length is 42.8mm / 10 flower nodes (average), and the circumferential flower node length is 20.7mm / 10 flower nodes (average). This embodiment is for a three-dimen...

Embodiment 2

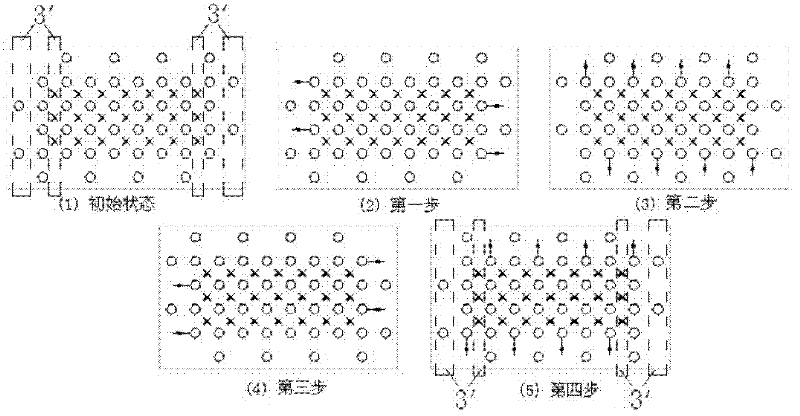

[0075] A three-dimensional five-direction, solid cubic preform is prepared by using the epoxy-type quartz yarn 190Tex two-ply ply, using the preform preparation method with expandable cross-sectional size, see Figure 2-4 shown. Preform size: 600mm×15mm×300mm (a×b×c), fiber volume content V f is 50%. Its preparation method is as follows:

[0076] (1) Example 1 is for a three-dimensional four-way structure preform, and its parent yarns are all fixed on the moving yarn carrier, and the "throwing-implanting" fiber bundle operation is only performed on the moving yarn carrier; For preforms with five-direction and above structures, in addition to the “throwing-implanting” fiber bundle operation performed by the moving yarn carrier according to step 2) of Example 1, an additional “throwing-out-implanting” fiber bundle operation on the axially immobile yarn carrier is required. -Implanting the fiber bundle operation, which constitutes a complete process cycle of "throwing-implanti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com