Method for realizing resource recycling of silicon powder components in waste mortar from crystalline silicon cutting

A technology of crystalline silicon cutting and waste mortar, which is applied in the direction of silicon, silicon carbide, carbide, etc., can solve the problems of long distance to form an industrial scale, achieve stable operation status, reduce the amount of pollutants, and reduce the amount of wastewater discharge. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

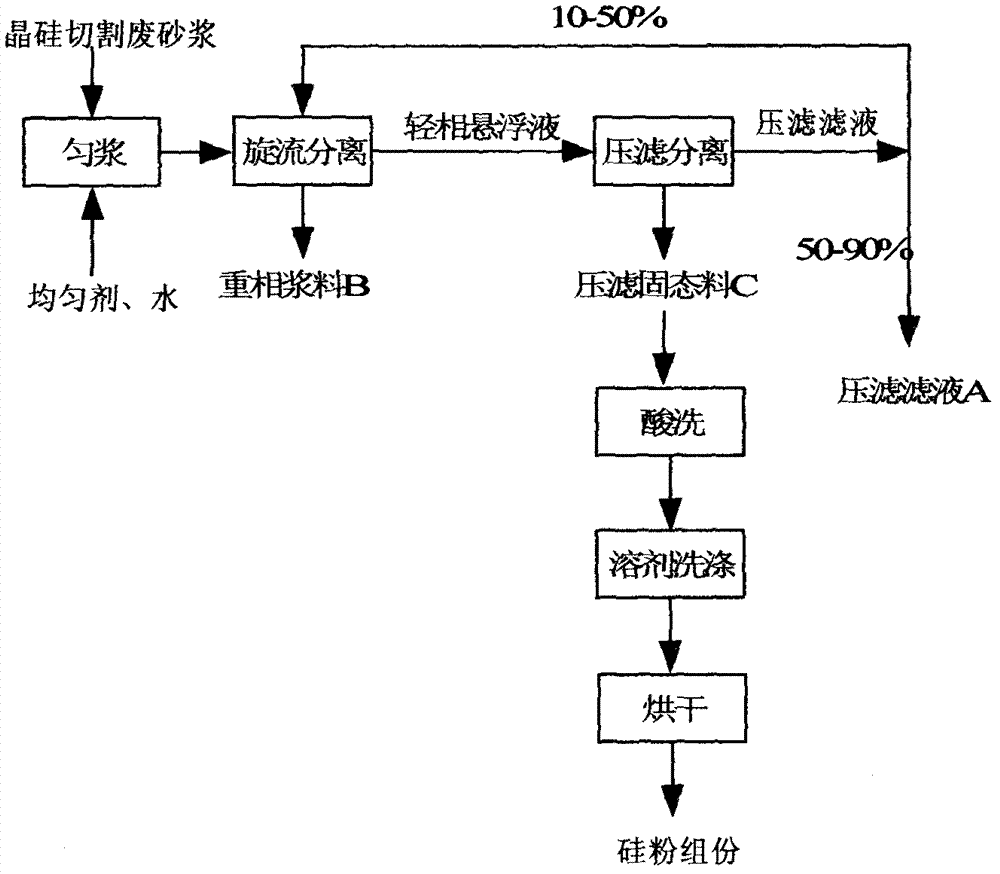

Image

Examples

Embodiment 1

[0025] A batch of crystalline silicon cutting waste mortar from Jiangxi LDK Solar High-tech Co., Ltd. was taken. The components of the waste mortar were tested as follows: cutting fluid component 42.0%, silicon carbide component 39.0%, silicon component 10.0% of water, 5.0% of water, 1.8% of metal components, 2.2% of pigments and cross-linked macromolecular substances.

[0026] Pour 10 tons of the above crystalline silicon cutting waste mortar into the mixing tank, add 500Kg Pingpingjia O-25, 10 tons of water; turn on the stirring and heating device, the stirring speed is 80r / min, raise the temperature to 60°C and keep it warm; the time for homogenization and stirring 2 hours. Transport the above-mentioned homogenized mortar material to the FXJ-50 cyclone separator in the form of continuous feeding, keep the cyclone separation temperature at 60°C and keep it warm, start the cyclone separator for 15 minutes, and start to The overflow port collects the light phase suspension. ...

Embodiment 2

[0032] Take a batch of crystalline silicon cutting waste mortar produced by Suzhou GCL Photovoltaic Technology Co., Ltd. After testing, the waste mortar components are as follows: cutting fluid component 40.7%, silicon carbide component 38.4%, silicon component 11.3% , 5.5% water, 1.9% metal components, 2.2% pigments and cross-linked macromolecular substances.

[0033] Pour 20 tons of the above crystalline silicon cutting waste mortar into the mixing tank, add 900Kg emulsifier OP-10, 15 tons of water; turn on the stirring and heating device, the stirring speed is 70r / min, raise the temperature to 55°C and keep it warm; 2.5 hours. Transport the above-mentioned homogenized mortar material to the FXJ-75 cyclone separator in the form of continuous feeding, keep the cyclone separation temperature at 55°C and keep it warm, start the cyclone separator for 25 minutes, and start The overflow port collects the light phase suspension. The above-mentioned light-phase suspension is trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com