Fixing clamp special for detecting wave buoys

A technology of wave buoys and fixing fixtures, which is applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve problems such as uneven force, fixture deformation, potential safety hazards, etc., and achieve easy installation, increase frame strength, and reduce deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content, characteristics and effects of the present invention, hereby give an example and describe in detail with accompanying drawings as follows:

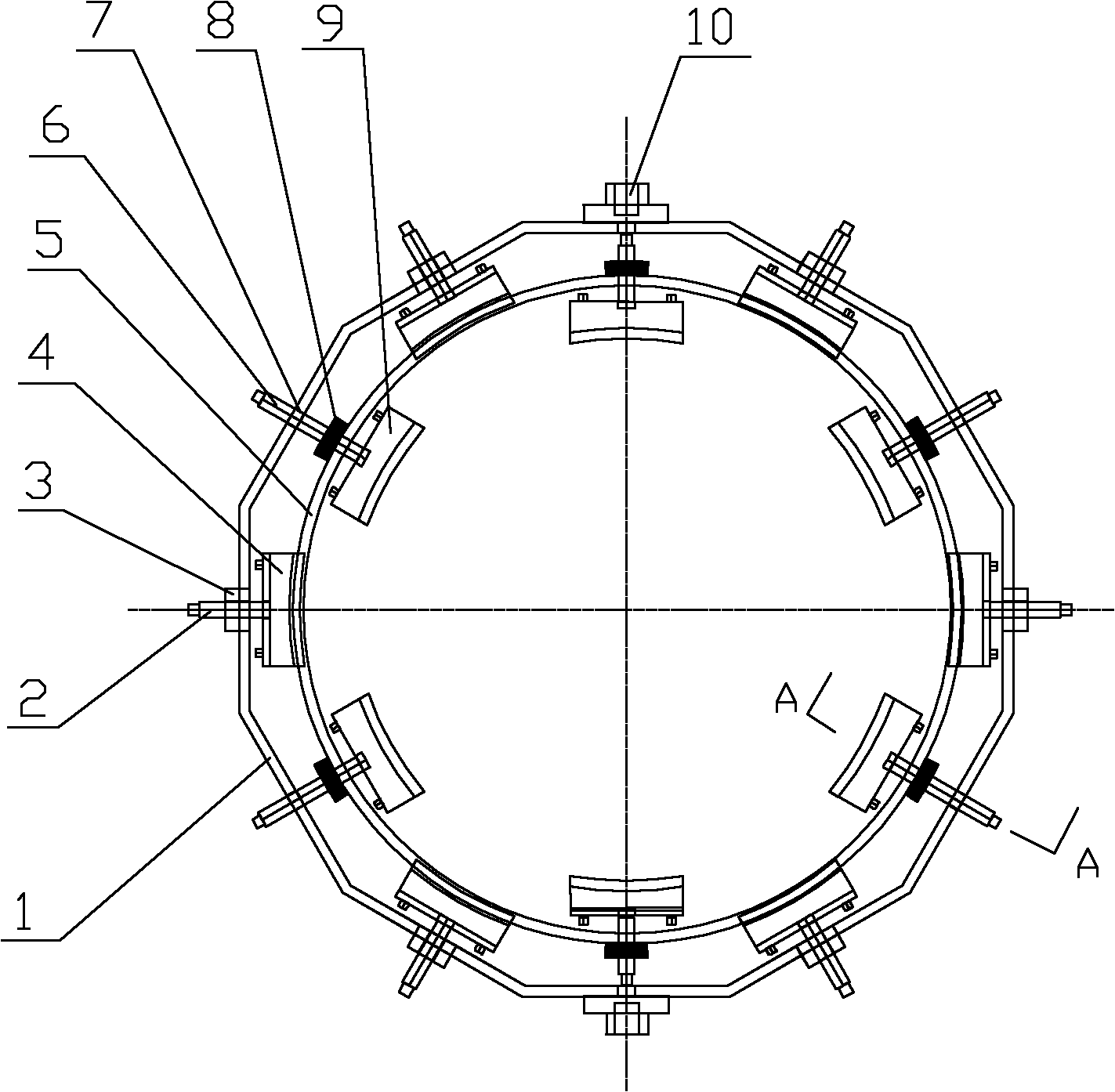

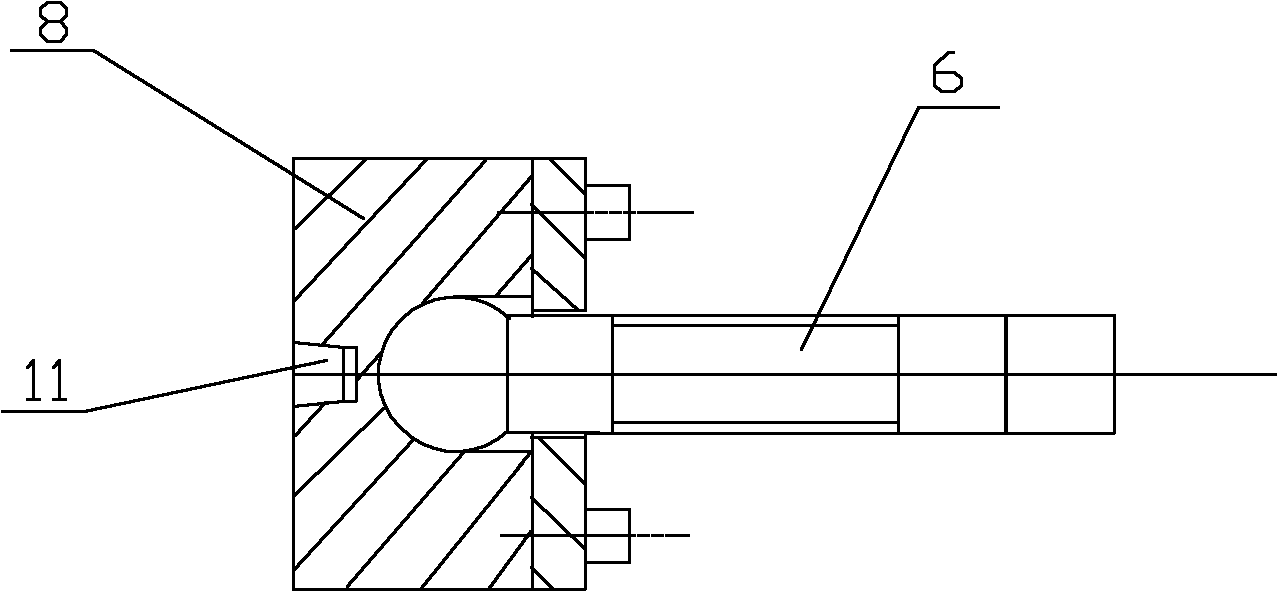

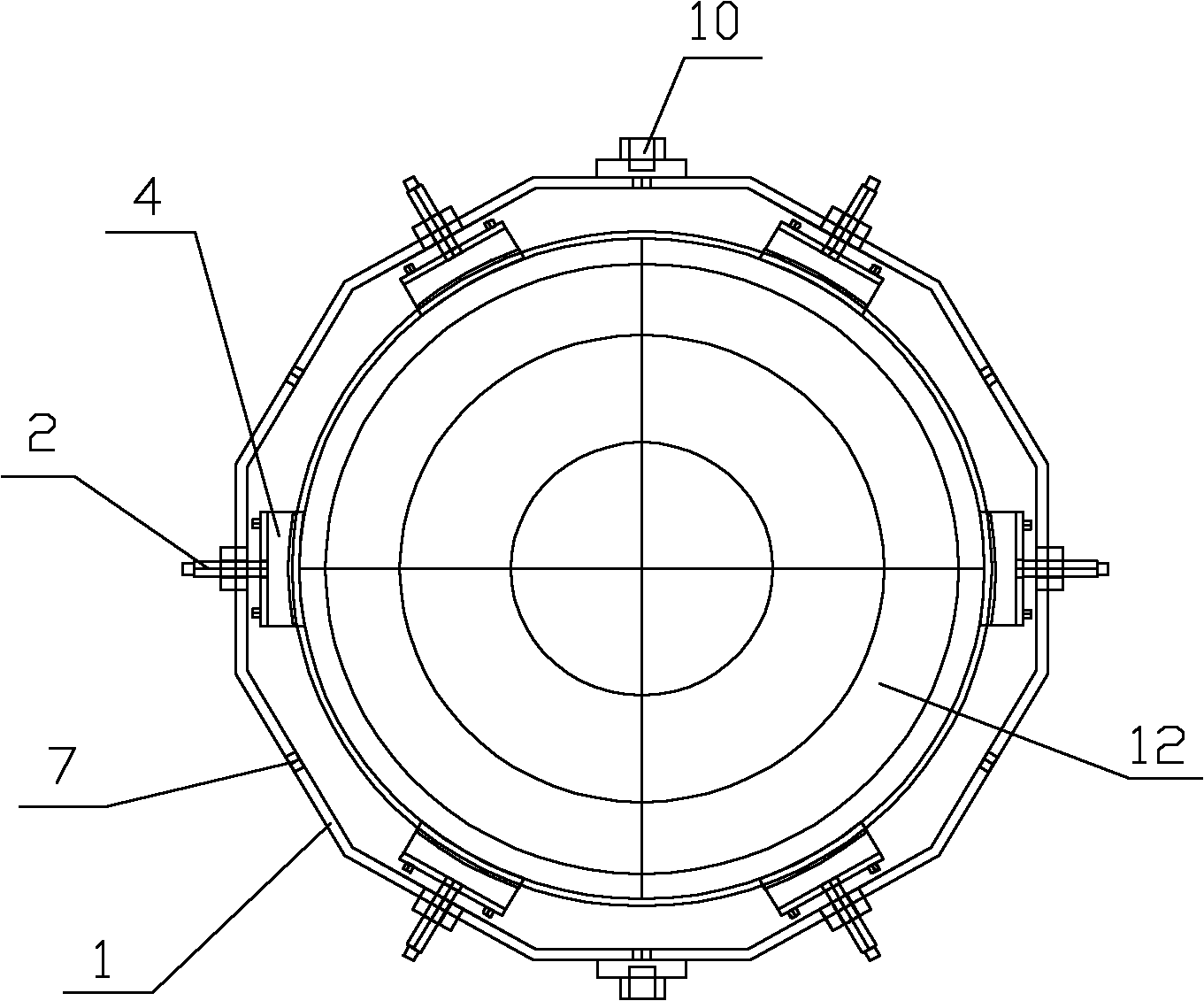

[0015] like figure 1 As shown, the annular frame 1 is a regular polygonal frame with 12 sides, and mounting blocks 10 for connecting the fixed shafts are symmetrically installed on both sides of the annular frame, and radial adjustment screw rods 2, locks, etc. are installed on the six symmetrical sides of the annular frame. Tight nut 3 and clamping block 4 thereof, each clamping block inner surface is shaped on U-shaped groove, also installs an annular frame 5 through each clamping block U-shaped groove, and 6 diameters are evenly installed on the peripheral side of circular ring frame. To the adjustment screw 6 and the lock nut 8, the regular polygonal frame is shaped on the through hole 7 corresponding to the adjustment screw, and the inner end of each radial adjustment screw is also e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com