Road surface milling machine

A milling machine and milling technology, applied in the field of road construction machinery, can solve the problems of only lifting, high labor intensity, and inability to mill and plan, and achieve the effects of convenient operation, reduced labor intensity, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

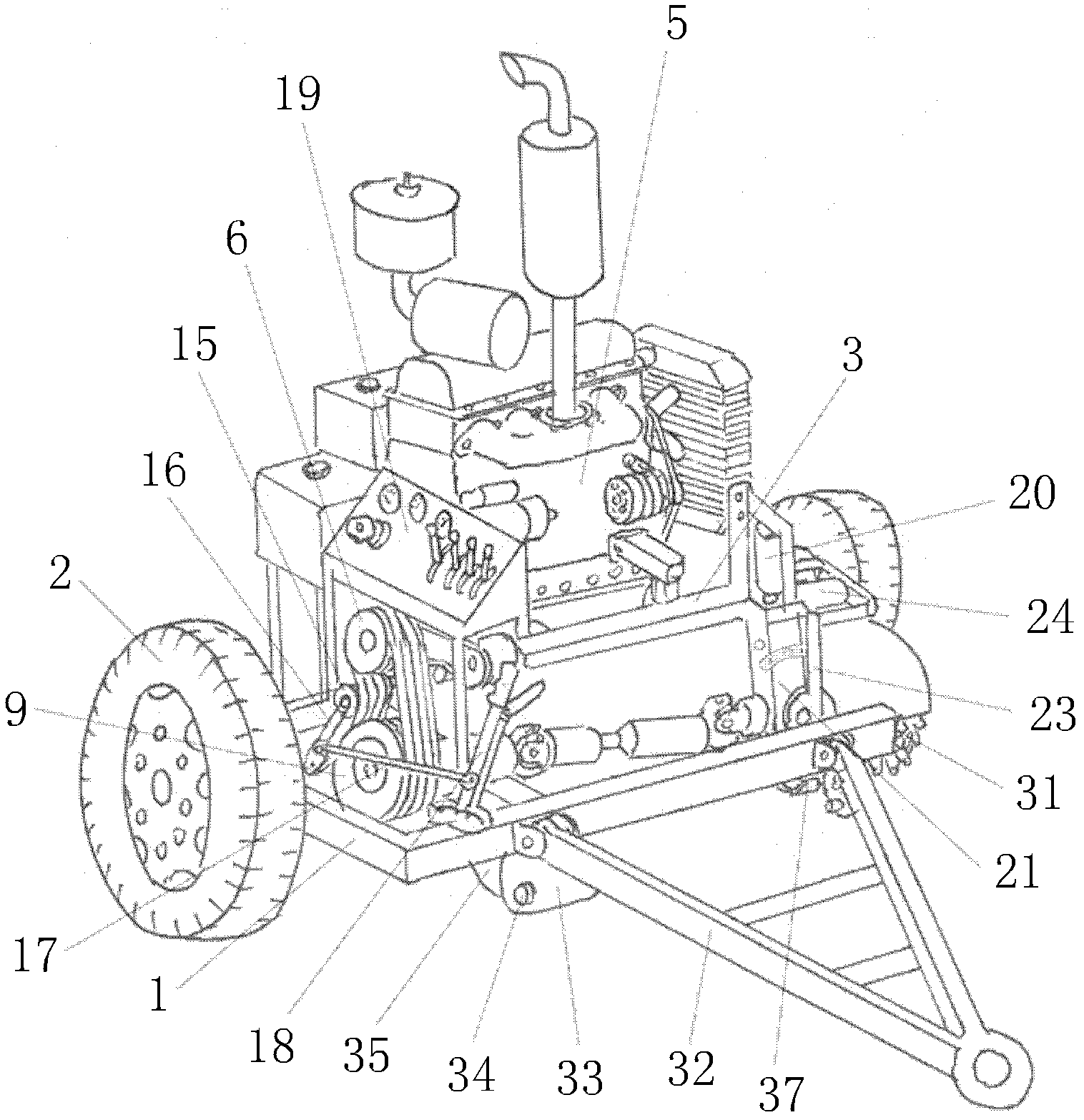

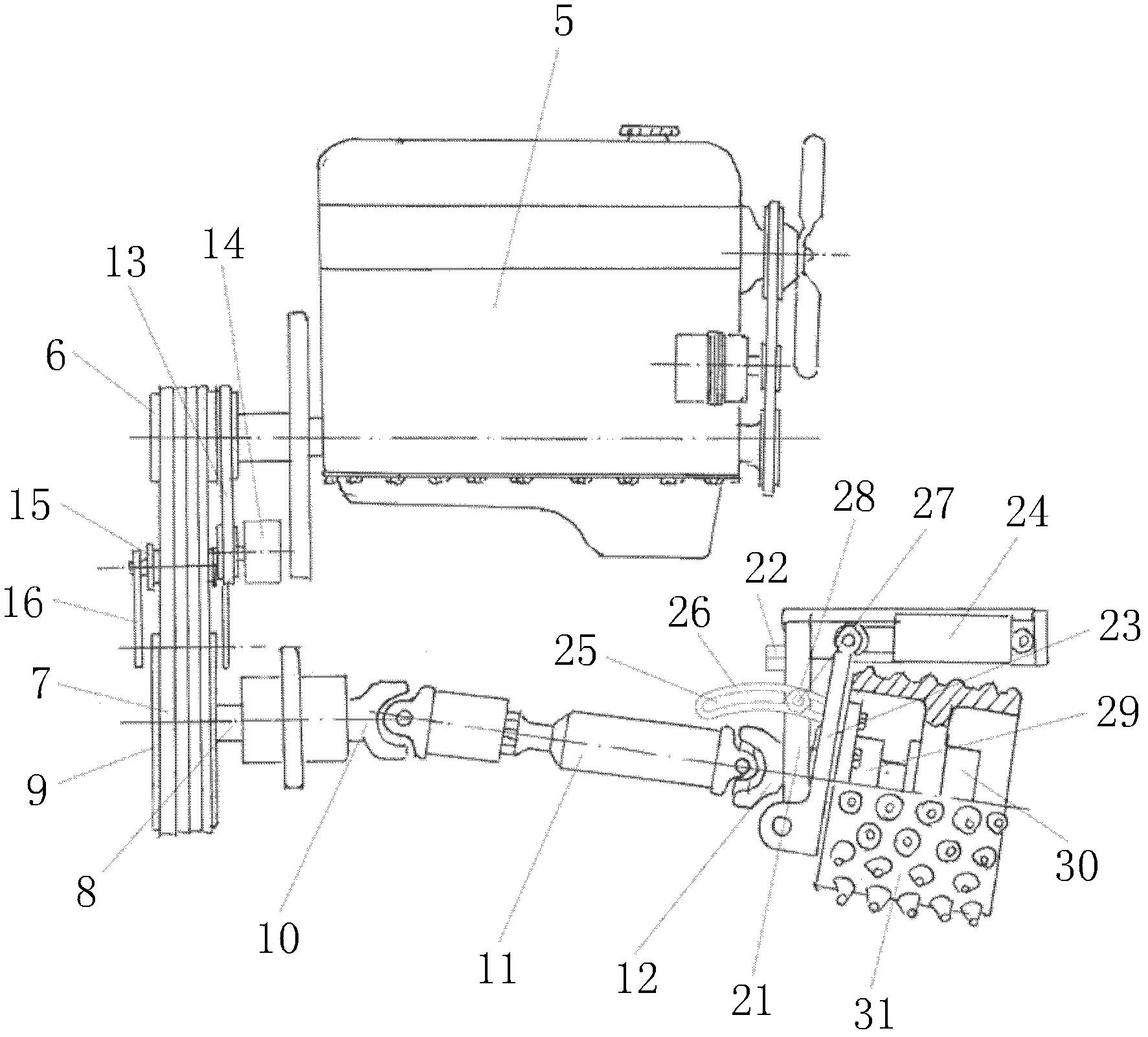

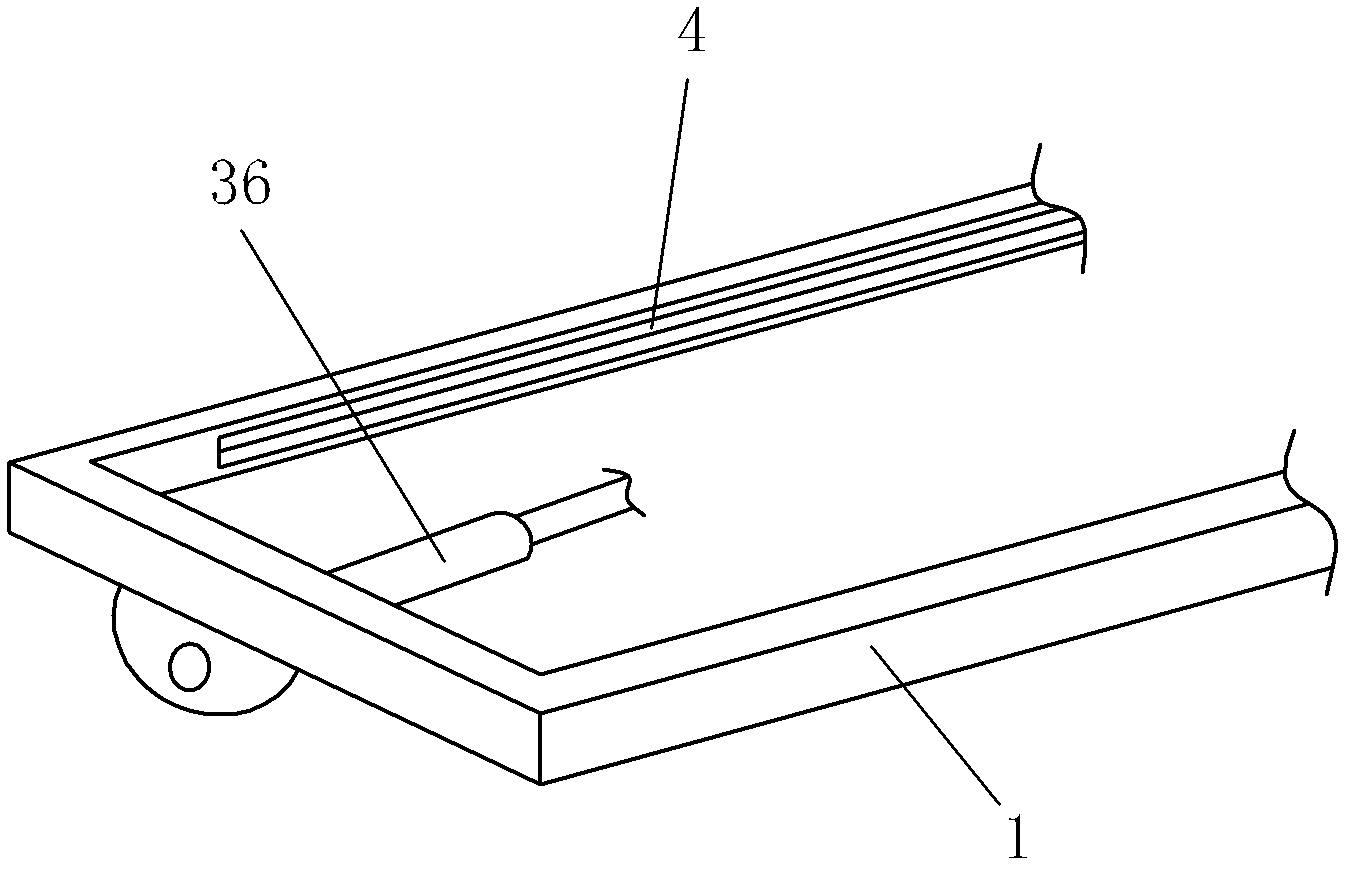

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0020] like Figure 1~3 Shown, the present invention comprises vehicle frame 1, is provided with wheel 2 at vehicle frame 1 left and right sides, is provided with traction device at vehicle frame 1 front, is provided with frame 3 above vehicle frame 1, and frame 3 bottom front and rear sides The side is inserted into the horizontal chute 4 on the vehicle frame 1, and a frame horizontal driving device is provided between the frame 3 and the vehicle frame 1; an internal combustion engine 5 is provided on the frame 1, and the output shaft of the internal combustion engine 5 is fixedly connected with Upper pulley 6, upper pulley 6 links to each other through the first belt 7 with the lower pulley 9 at one end of the intermediate shaft 8, which is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com