Continuous damping real-time on-line linear backwashing high-flux disc-type micro-screen assembly

A backwashing, disc-type technology, applied in the field of high-flux disc-type micro-grid components, can solve the problems of unstable flux and water quality, affecting the packing density of components, increasing frictional resistance in the cavity, etc., to achieve stability and improve water output. Water quality, solving uneven generation, and improving the effect of mesh surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

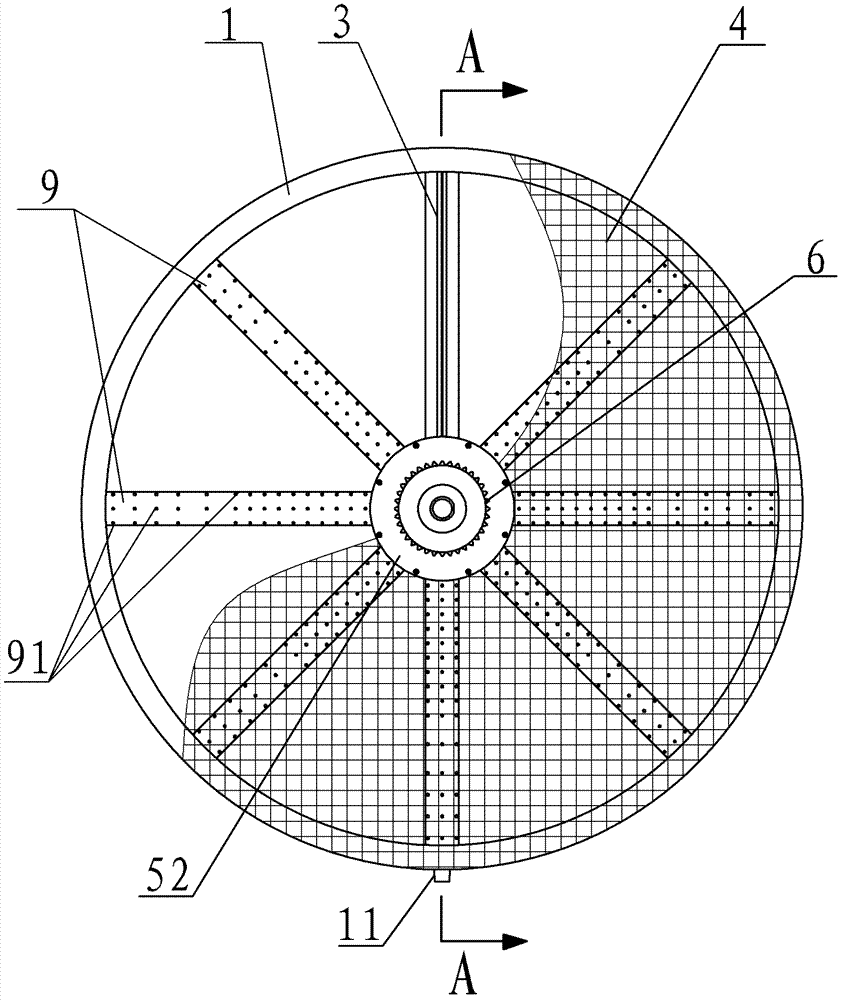

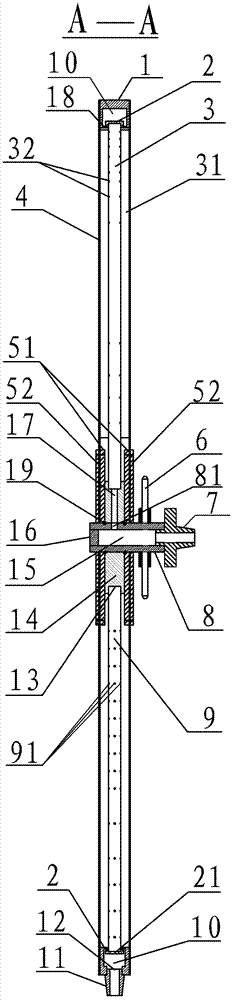

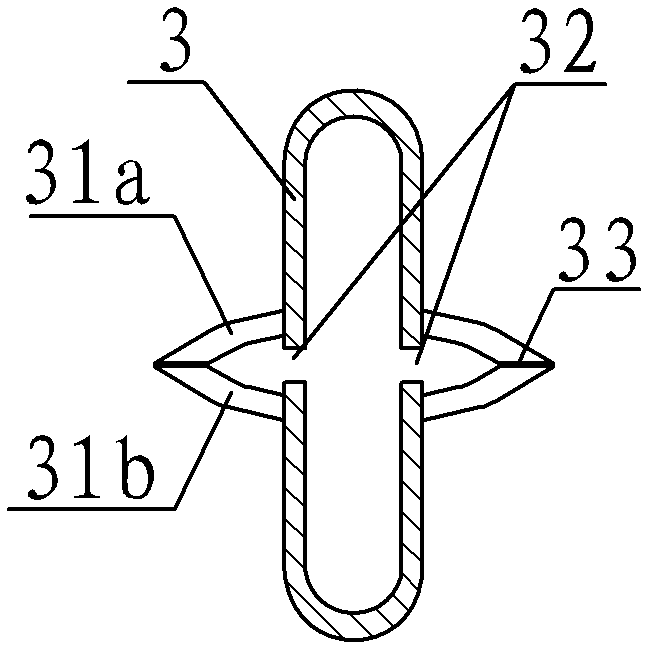

[0024] Figure 1 ~ Figure 4 It shows a continuous vibration reduction real-time online linear backwashing high-throughput disc micro-mesh assembly, including a cavity filter box formed by a rigid impermeable enclosure and a micro-mesh matrix fixed and packaged on both ends of the enclosure, and a reverse The flushing pipe and the water collection pipe 9 are characterized in that the filter box is a disc-shaped filter box formed by a circular ring frame 1 and a micro-mesh matrix encapsulated on both ends of the frame, and is set at the center of the filter box. The backwash water delivery shaft 8 with the water inlet chamber 15 passing through the filter box perpendicular to the disk surface is cylindrical. Backwash water inlet swivel joint 7. The backwash water inlet rotary joint 7 is relatively rotatably connected to the port of the backwash water delivery rotating shaft 8 , which can be used as a connector to be connected between the dynamic backwash water delivery rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com