Paper conveying mechanism

A paper conveying and conveying mechanism technology, applied in the directions of transportation and packaging, object supply, positioning objects, etc., can solve problems such as paper skew or offset, and achieve the effect of preventing movement, ensuring the accuracy of detection, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

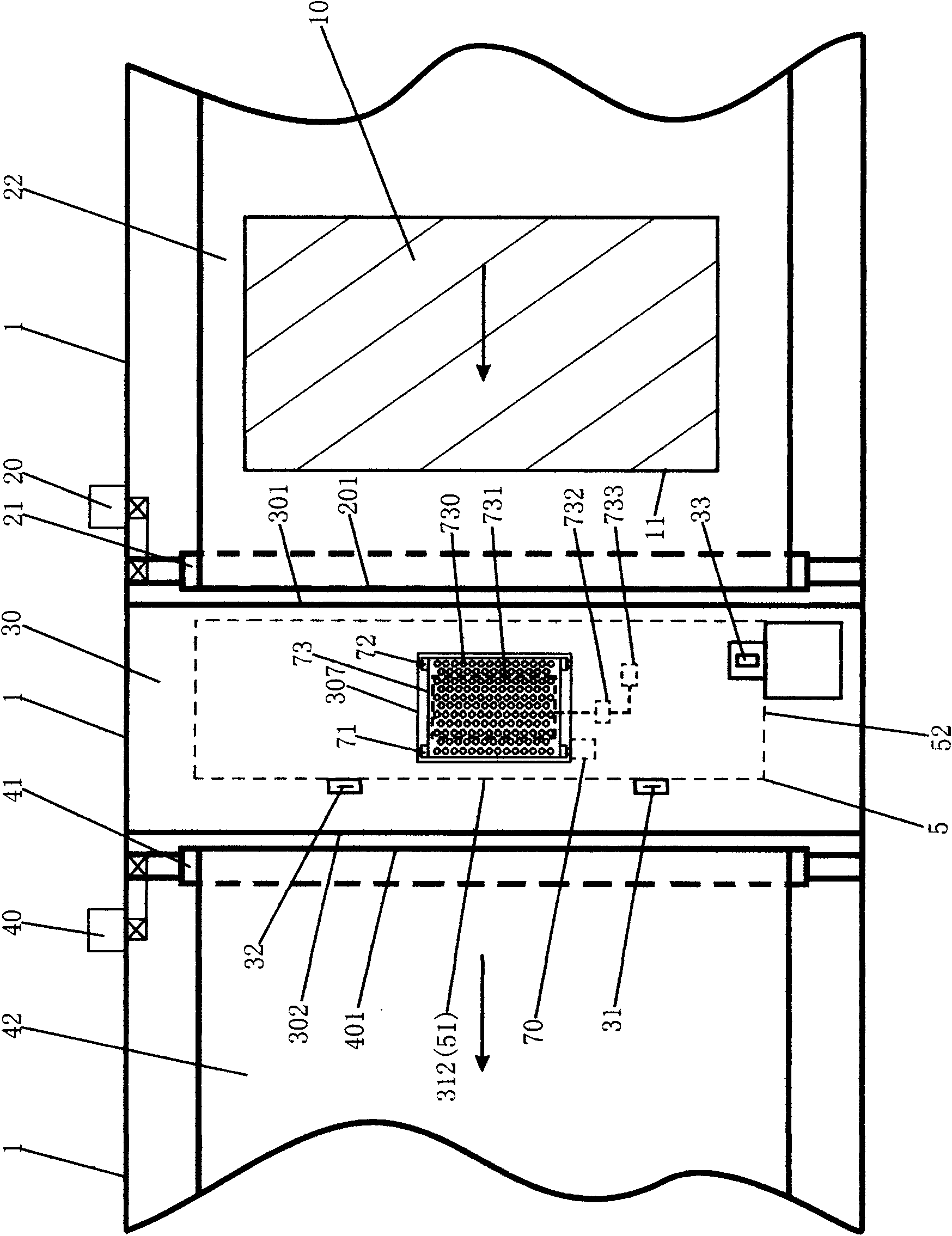

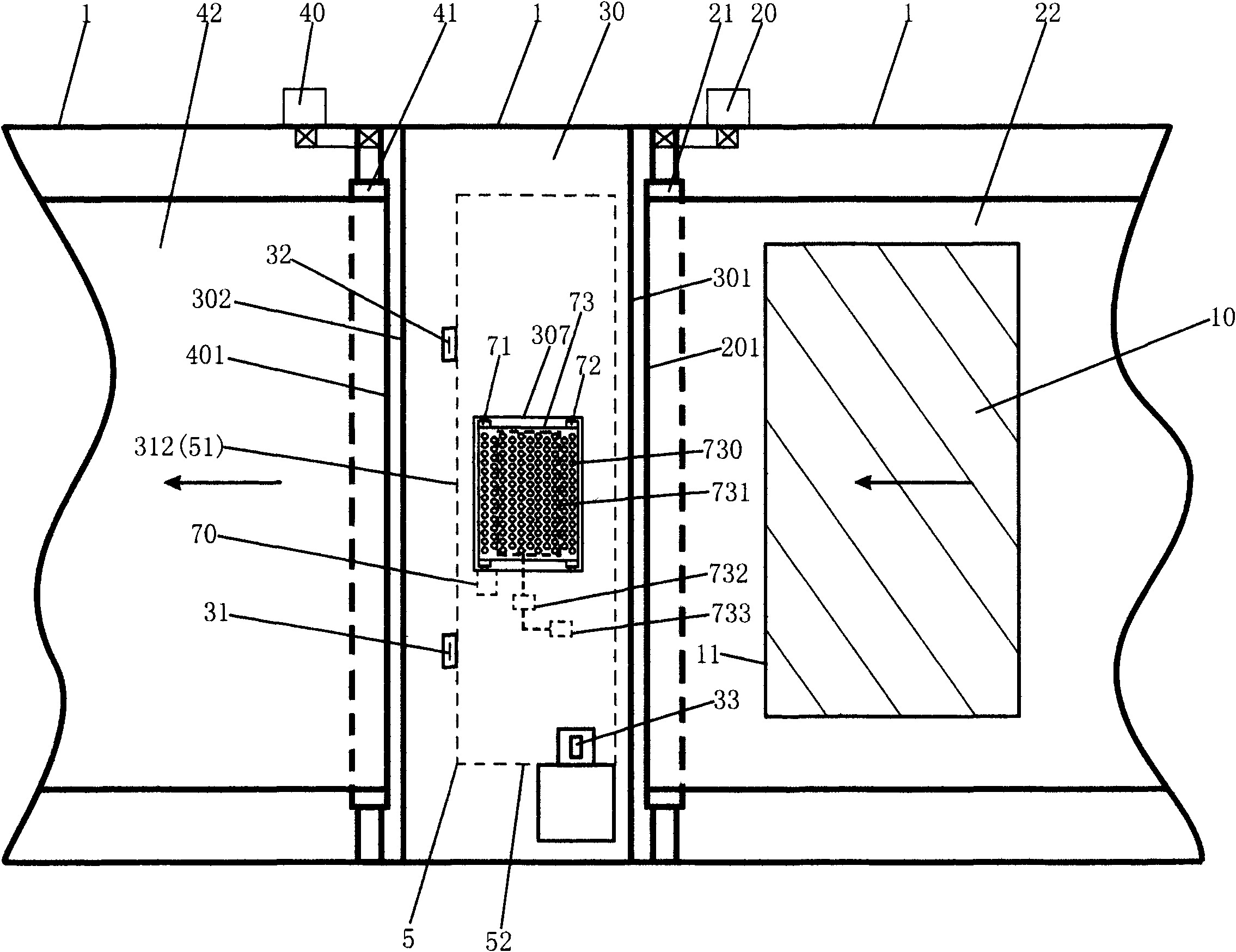

[0027] As shown in the accompanying drawings, the paper conveying mechanism in this preferred embodiment includes a frame 1 and a paper feeding mechanism, a deviation correcting suction paper feeding mechanism and a paper output mechanism arranged on the frame 1 in sequence;

[0028] The paper feed mechanism includes a paper feed motor 20, a paper feed drive roller 21 and a paper feed conveyor belt 22;

[0029] The above-mentioned deviation-correcting and absorbing paper-feeding mechanism includes a paper positioning platform 30, a paper-correcting and limiting mechanism, and a paper-adsorbing conveying mechanism; the above-mentioned paper-correcting and limiting mechanism includes a left front gauge 31, a right front gauge 32 and a side pull gauge 33; the paper absorbing and conveying mechanism Adopt paper-absorbing conveyor belt mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com