Device special for site processing of large-scale hydrogenerator rotor spider stud

A technology of hydroelectric generator and rotor support, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc., to achieve the effect of ensuring the installation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

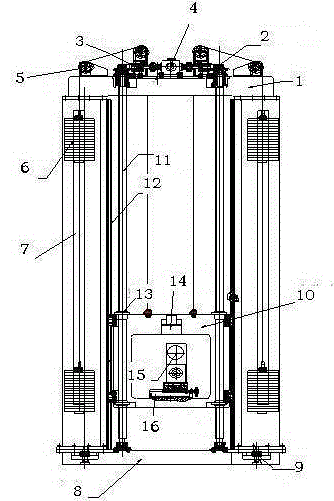

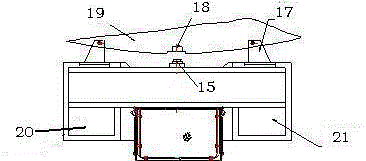

[0020] Such as figure 1 As shown, this special equipment has a frame structure composed of a base 8, left and right uprights 20 and 21, and a cross beam 1. The equipment is also equipped with a level adjustment device 9, which is composed of 4 screws, lock nuts and pressure blocks arranged on the legs of the base. The level adjustment device 9 is supported on the ground and can be adjusted by rotating the 4 screws. The horizontality keeps the columns 20, 21 and the linear guide 12 upright to ensure that the special equipment can also perform normal milling work on the ground that is not flat enough. A lifting platform 10 is arranged between the left and right upright columns 20 and 21, and two screw rods 11 that are connected to the lifting platform and drive the lifting platform to move up and down are arranged on both sides of the lifting platform. Sliders (not shown) are provided on both sides of the lifting platform 10, and slide along the two linear guides 12 inside the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com