Method and device for machining inner blind hole of perforating gun for oil-gas well

A processing device and processing method technology, applied in boring/drilling, metal processing equipment, drilling/drilling equipment, etc., can solve the problems of unstable tool rotation, reduced device use efficiency, insufficient rigidity, etc. Low cost and equipment maintenance cost, elimination of discontinuous cutting power transmission, and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The parameters of the inner blind hole on the perforating gun body are: hole density: 16 holes / m, phase: 90°, distance between adjacent holes: 62.5mm, inner blind hole drilling depth: 5±0.5mm, inner blind hole diameter : Φ26mm, perforating gun body length: 6m.

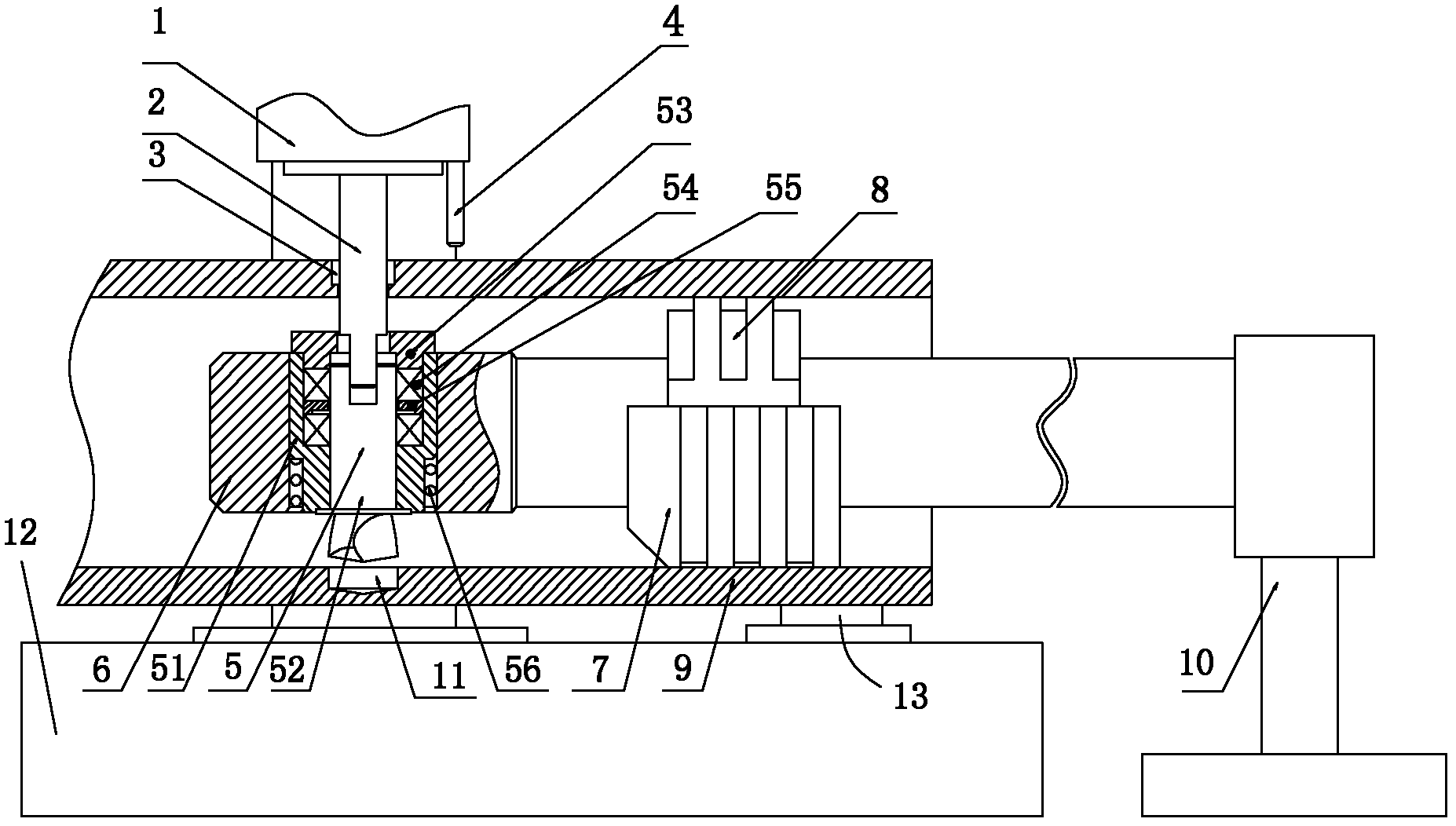

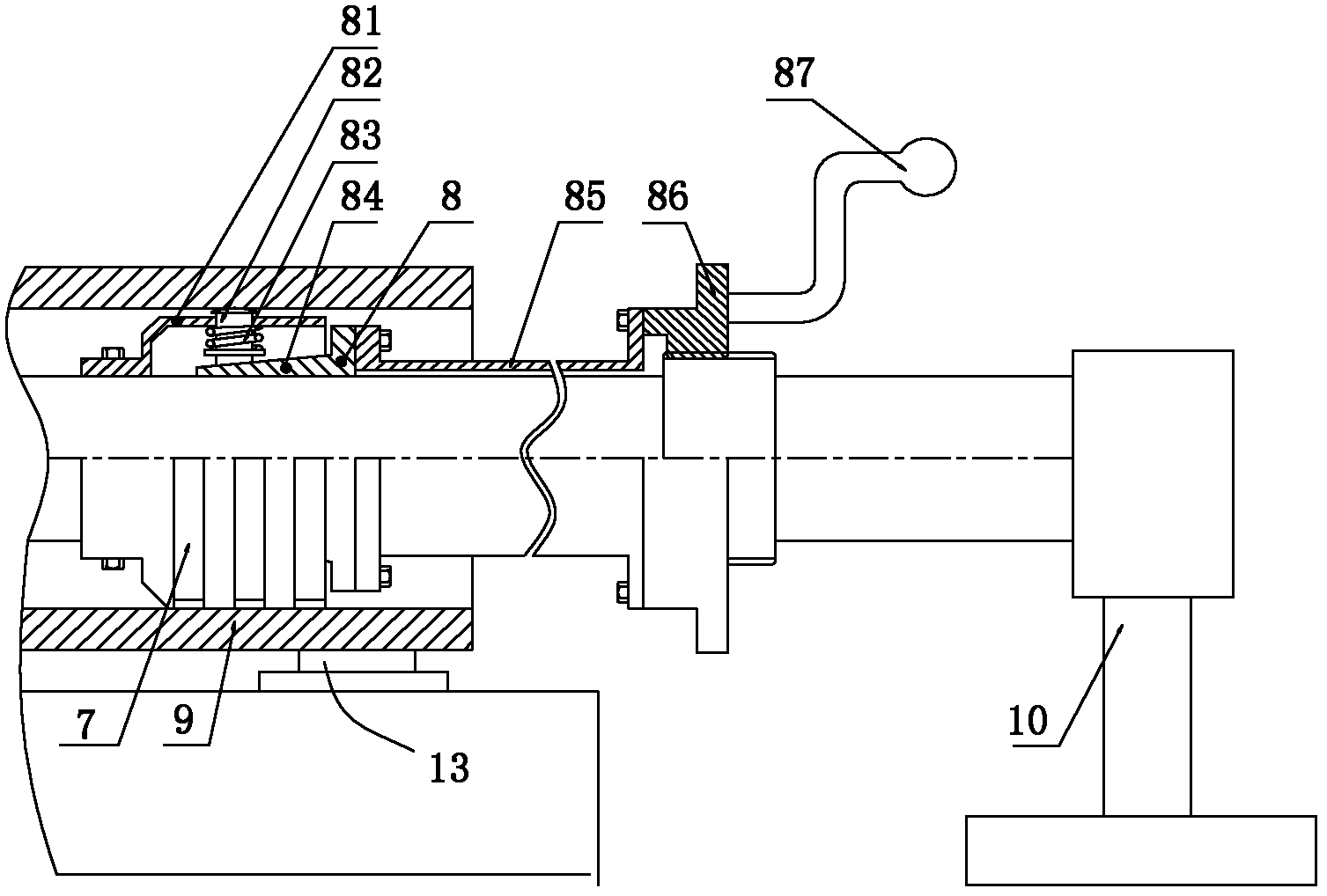

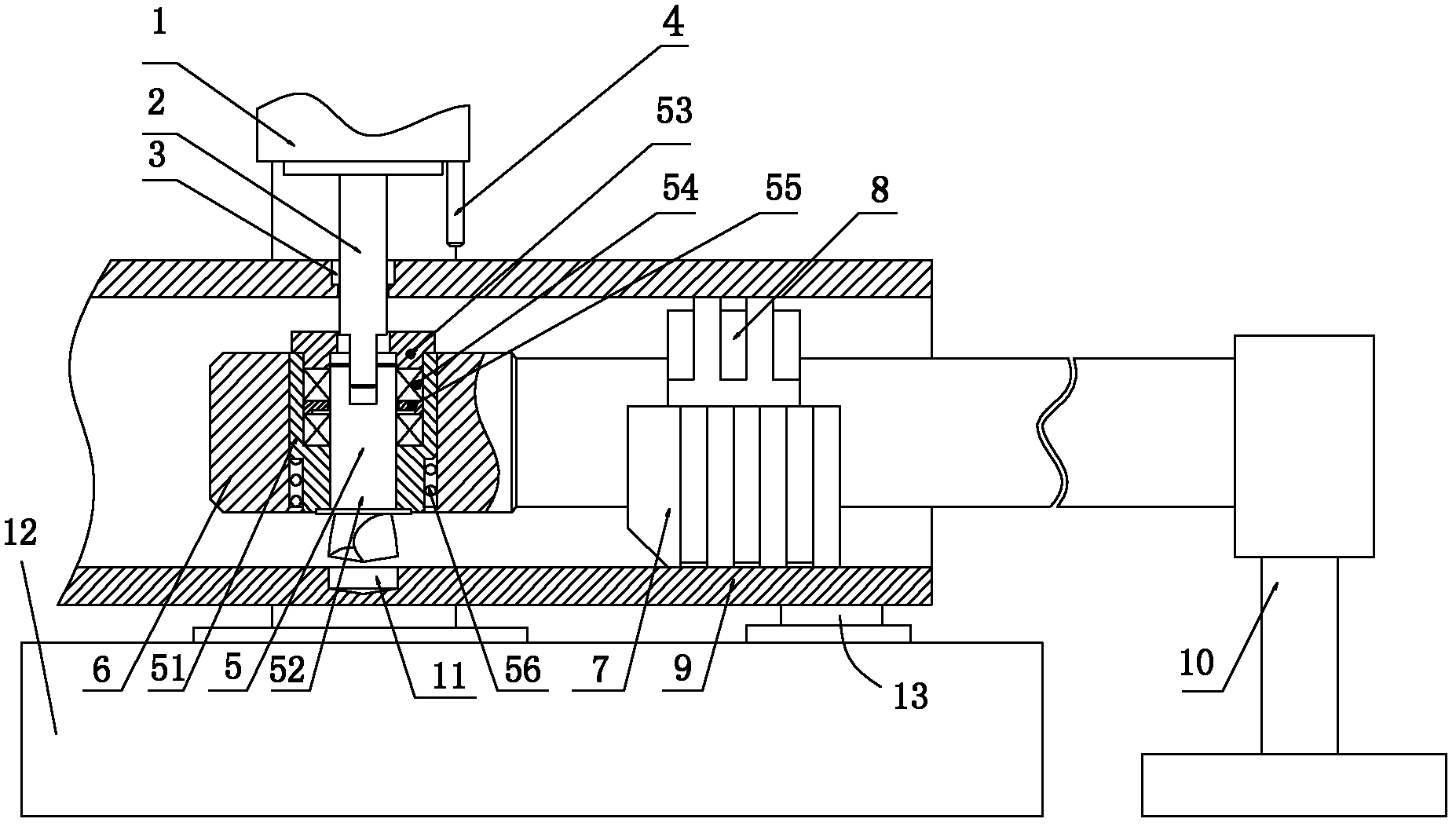

[0031] Such as figure 1 As shown, the blind hole processing device includes a vertical milling machine 1 , a drill assembly 5 , a tool connecting rod 6 , a bracket 10 , a tool connecting rod support seat 7 and an expansion mechanism 8 . The drilling tool assembly 5 is installed at the end of the connecting rod of the cutter, and it is mainly composed of a sliding sleeve 51, a drill bit 52 and a return spring 56. Between the tool connecting rod steps, that is, the sliding sleeve 51 is supported on the return spring 56 .

[0032] Two bearings 54 are arranged between the drill bit 52 and the sliding sleeve 51, a bearing washer 55 is arranged between the two bearings 54, and a bearing gland 53 is used for axial po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com