Production technology of low-salt dried small shrimps

A production process and low-salinity technology, which is applied in the field of low-salinity shrimp peel production technology, can solve the problems of difficult cross-regional sales, easy moldy deterioration, spoilage and other problems, achieve good practical value and application prospects, improve market competitiveness, The effect of preventing spoilage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

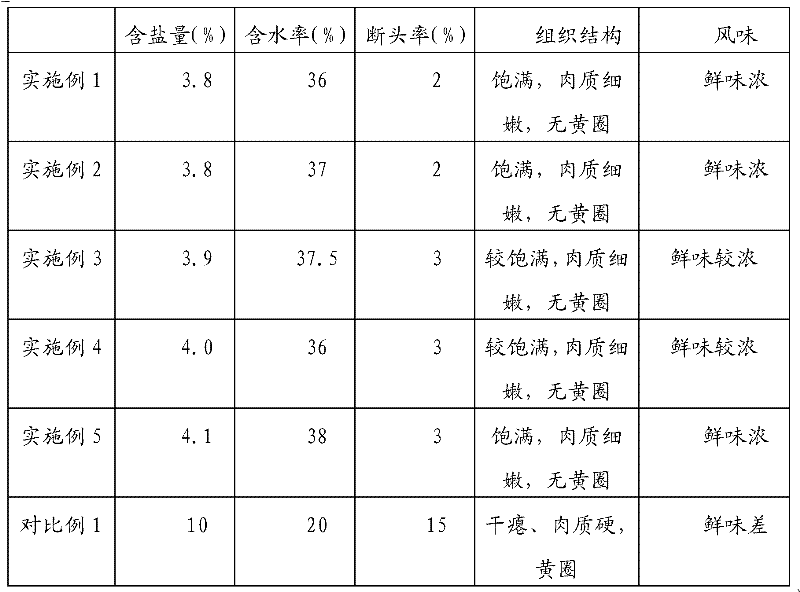

Examples

Embodiment 1

[0025] A kind of low-salinity shrimp skin production technology, comprises the steps:

[0026] 1) rinse

[0027] Rinse the shrimp skin with flowing water to remove seawater, microorganisms and sand remaining on the surface, reduce the salt content, and then drain;

[0028] 2) Cooking

[0029] Adding brine with a mass ratio of salt to water of 2:100, and a mass ratio of shrimp to brine of 1:4, and then cooking at a cooking temperature of 95° C. and a cooking time of 4 minutes;

[0030] 3) vacuum drying

[0031] Shrimp skins with a thickness of 25 mm to 35 mm are first vacuum-dried at 55°C for 25 minutes, and after taking them out, evenly spray 1% salt water on the surface of the dried shrimp skins, and then vacuum-dry them at 70°C for 15 minutes; the vacuum degree is 0.04MPa;

[0032] 4) Packaging and storage

[0033] According to the demand, the shrimp skins are weighed and packed into BOPP film materials. Under the condition of a vacuum of 450 mm Hg, they are vacuum-pack...

Embodiment 2

[0035] A kind of low-salinity shrimp skin production technology, comprises the steps:

[0036] 1) rinse

[0037] Rinse the shrimp skin with flowing water to remove seawater, microorganisms and sand remaining on the surface, reduce the salt content, and then drain;

[0038] 2) Cooking

[0039] Adding brine with a mass ratio of salt to water of 1:100 to the shrimp, the mass ratio of the shrimp to the brine is 1:4, and then cooking at a cooking temperature of 98° C. and a cooking time of 5 minutes;

[0040] 3) vacuum drying

[0041] Shrimp skins with a thickness of 25 mm to 35 mm were first vacuum-dried at 55°C for 25 minutes, and after taking them out, evenly sprayed salt water with a mass percentage concentration of 1% on the surface of the dried shrimp skins, and then vacuum-dried at 70°C for 20 minutes; the vacuum degree was 0.04MPa;

[0042] 4) Packaging and storage

[0043] According to the demand, the shrimp skins are weighed and packed into BOPP film materials. Under...

Embodiment 3

[0045] A kind of low-salinity shrimp skin production technology, comprises the steps:

[0046] 1) rinse

[0047] Rinse the shrimp skin with flowing water to remove seawater, microorganisms and sand remaining on the surface, reduce the salt content, and then drain;

[0048] 2) Cooking

[0049] Adding brine with a mass ratio of salt to water of 1:100 to the shrimp, and a mass ratio of shrimp to brine of 1:4, and then cooking at a cooking temperature of 95° C. and a cooking time of 5 minutes;

[0050] 3) vacuum drying

[0051] Shrimp skins with a thickness of 25 mm to 35 mm were first vacuum-dried at 55°C for 30 minutes, and after taking them out, evenly sprayed salt water with a concentration of 1% by mass on the surface of the dried shrimp skins, and then vacuum-dried at 70°C for 20 minutes; the vacuum degree was 0.045MPa;

[0052] 4) Packaging and storage

[0053] According to the demand, the shrimp skins are weighed and packed into BOPP film materials. Under the conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com