Welding nut

A technology of nuts and caps, which is applied in the field of structural improvement of welding nuts and flat welding nuts, which can solve the problems of workpiece damage and high temperature, and achieve the effect of firm and reliable welding and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

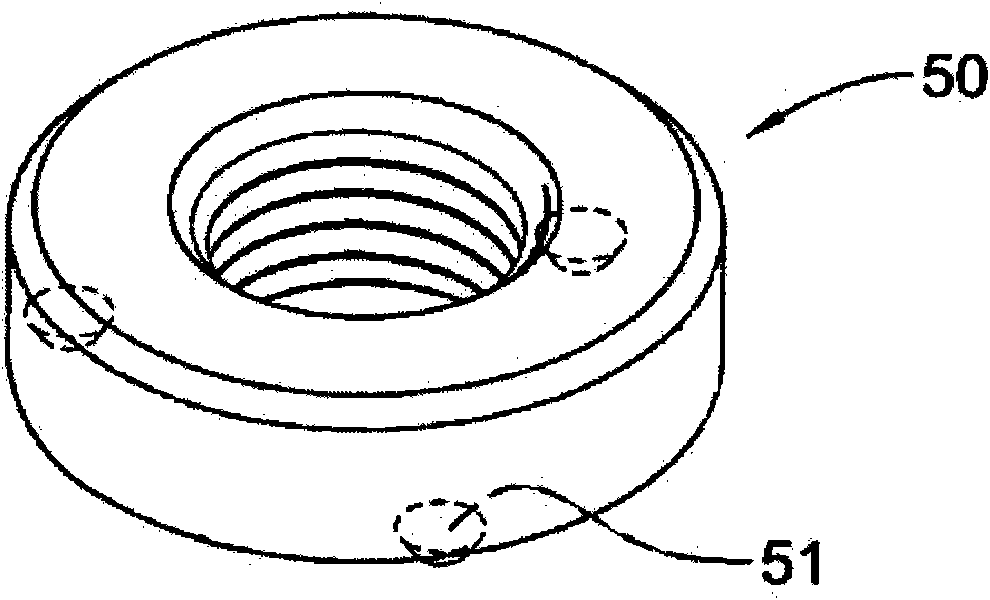

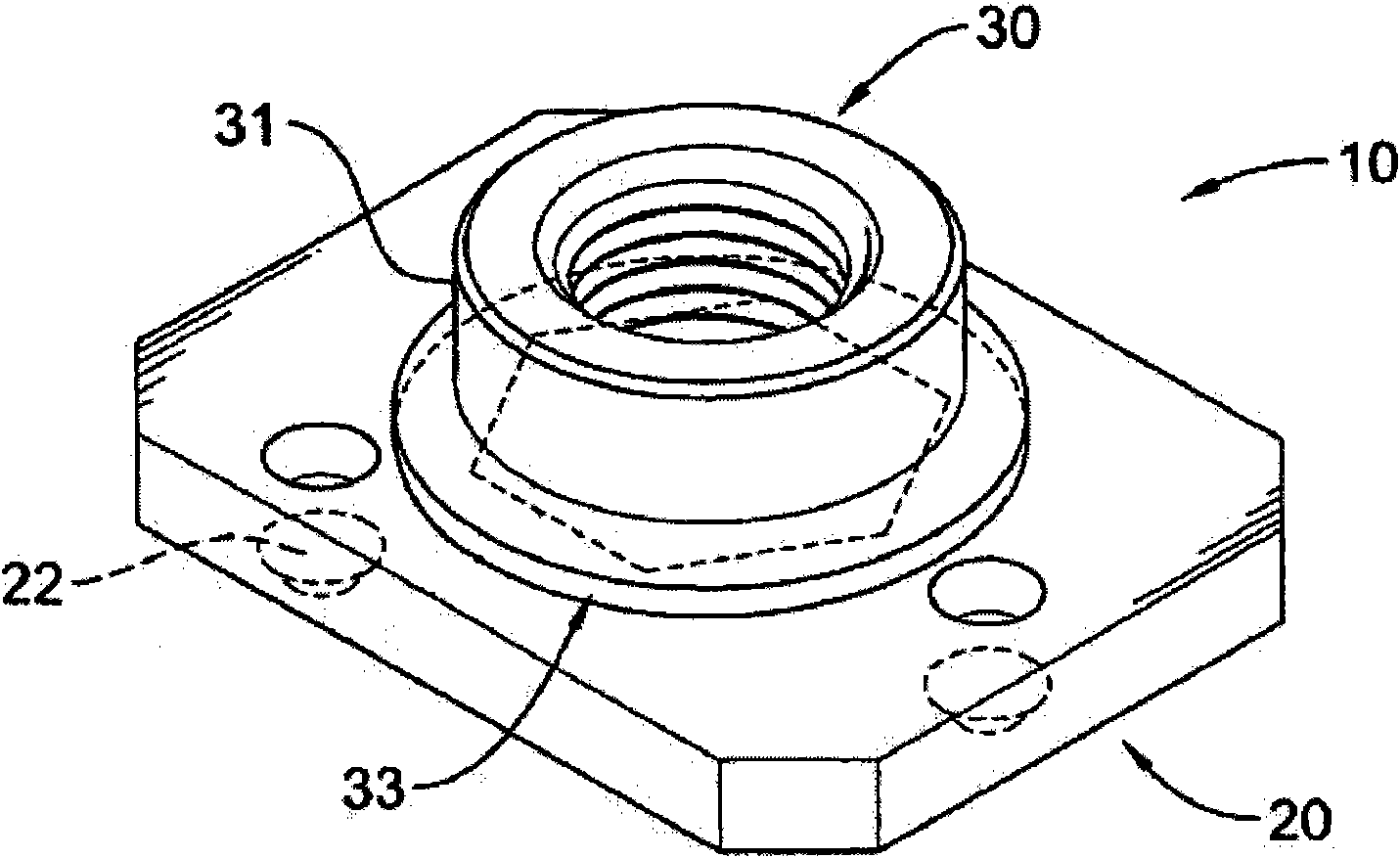

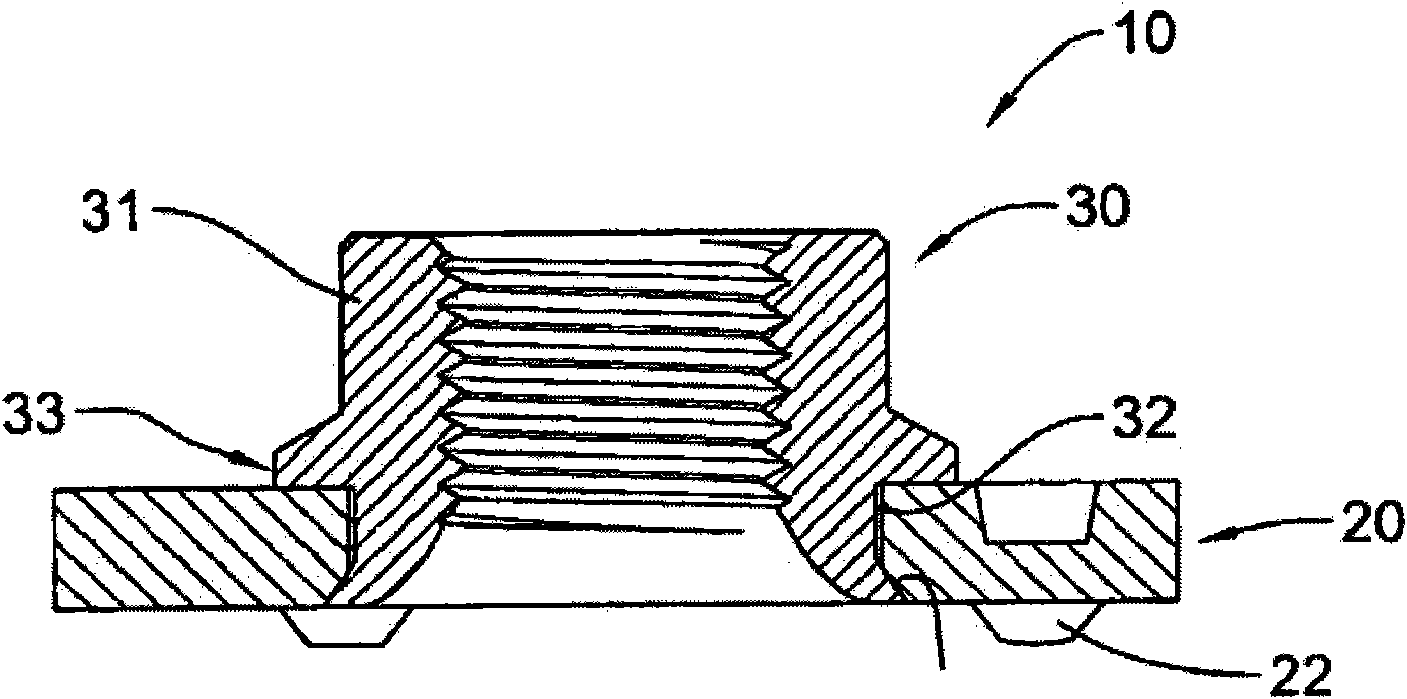

[0014] see figure 2 and image 3 As shown, the present invention is a welding nut 10 , which includes a flat piece 20 and a nut piece 30 . A perforation 21 is formed on the flat member 20 , and a welding protrusion 22 is formed at the bottom thereof. The upper end of the nut member 30 has a cylindrical cap portion 31 , the lower end has a joint portion 32 , and a screw hole 34 is formed in the center thereof, and the screw hole 34 axially passes through the cap portion 31 and the joint portion 32 . A disk 33 is disposed at the connection between the cap portion 31 and the joint portion 32 , the joint portion 32 is fixed in the through hole 21 of the flat piece 20 , and the bottom of the disk 33 abuts against the top of the flat piece 20 .

[0015] The welding protrusion 22 at the bottom of the flat piece 20 of the flat welding nut 10 of the present invention is welded on a workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com