Shotcrete additive and spraying technology of shotcrete

A technology of sprayed concrete and admixtures, which is applied in the field of sprayed concrete admixtures and shotcrete spraying technology, can solve the problems of high dust concentration, achieve the effects of reducing dust concentration, reducing rebound rate, and reducing alkali corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

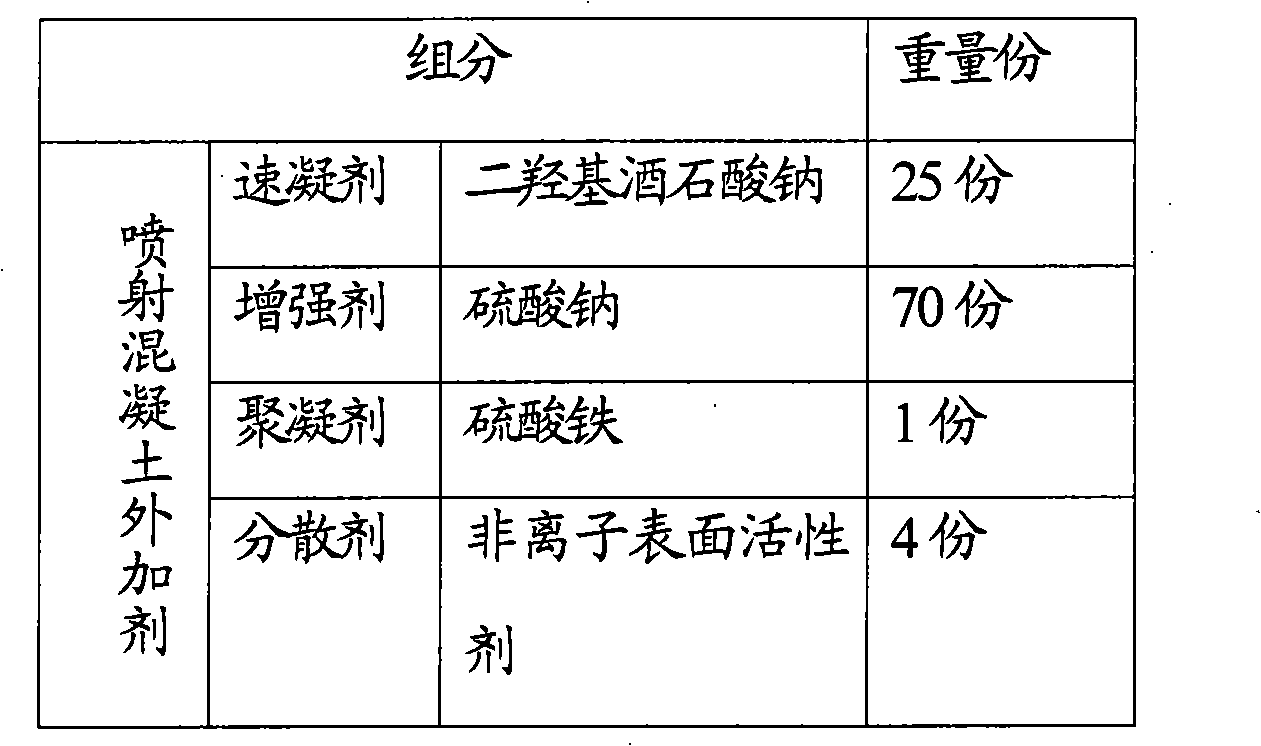

[0028] The spraying process of sprayed concrete provided by the present invention is specifically described through this embodiment. The composition of shotcrete admixture is shown in Table 1:

[0029] Table I

[0030]

[0031] Among them, the standards for the aggregate used in the spraying operation using the above-mentioned sprayed concrete admixture are: cement: P.O 42.5, stone: maximum particle size ≤ 5mm, sand: medium sand; the weight ratio of cement, cement, and sand in the aggregate is 1 : 2: 2; when the ambient temperature of the shotcrete construction site was 20°C, the admixture of the shotcrete admixture was about 3% of the cement weight, and the admixture of the shotcrete admixture could be based on the ambient temperature The reduction or increase of the appropriate increase or decrease.

[0032] Shotcrete spraying process:

[0033] Pour the sprayed concrete admixture (30kg) into the liquid mixing container (the liquid mixing container is made of corrosion-...

Embodiment 2

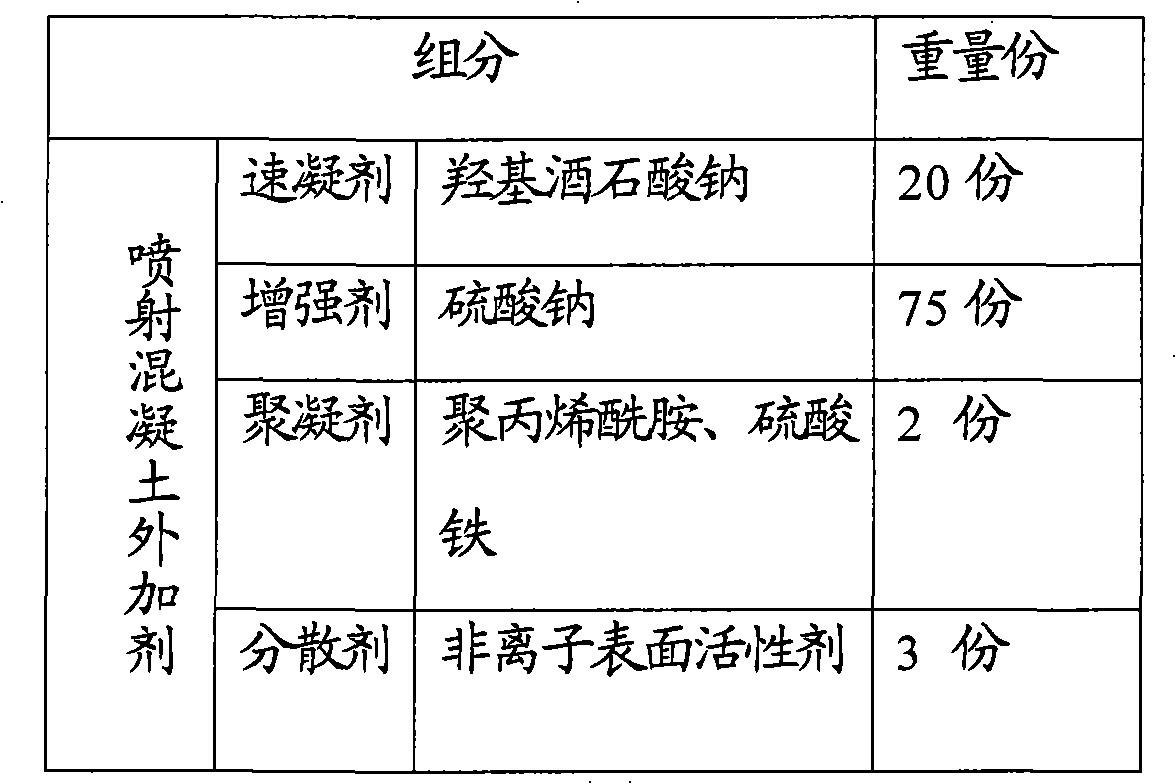

[0043] According to the spraying process of sprayed concrete of embodiment one, wherein the composition of sprayed concrete admixture can also be, as shown in table two:

[0044] Table II

[0045]

[0046] Wherein, the standard of the aggregate used when using the sprayed concrete admixture of this embodiment for spraying operations is: cement: P.O 42.5, stone: maximum particle size ≤ 5mm, sand: medium sand; the weight of cement, cement, and sand in the aggregate The ratio is 1: 2: 2; when the ambient temperature of the construction site is 20°C, the admixture of the shotcrete admixture is about 3% of the cement weight, and the admixture of the shotcrete admixture can be adjusted according to the environment. The decrease or increase of temperature is appropriately increased or decreased.

[0047] Specific spraying process: except that the composition of the sprayed concrete admixture in Table 1 is adjusted to the composition of Table 2, the specific implementation process...

Embodiment 3

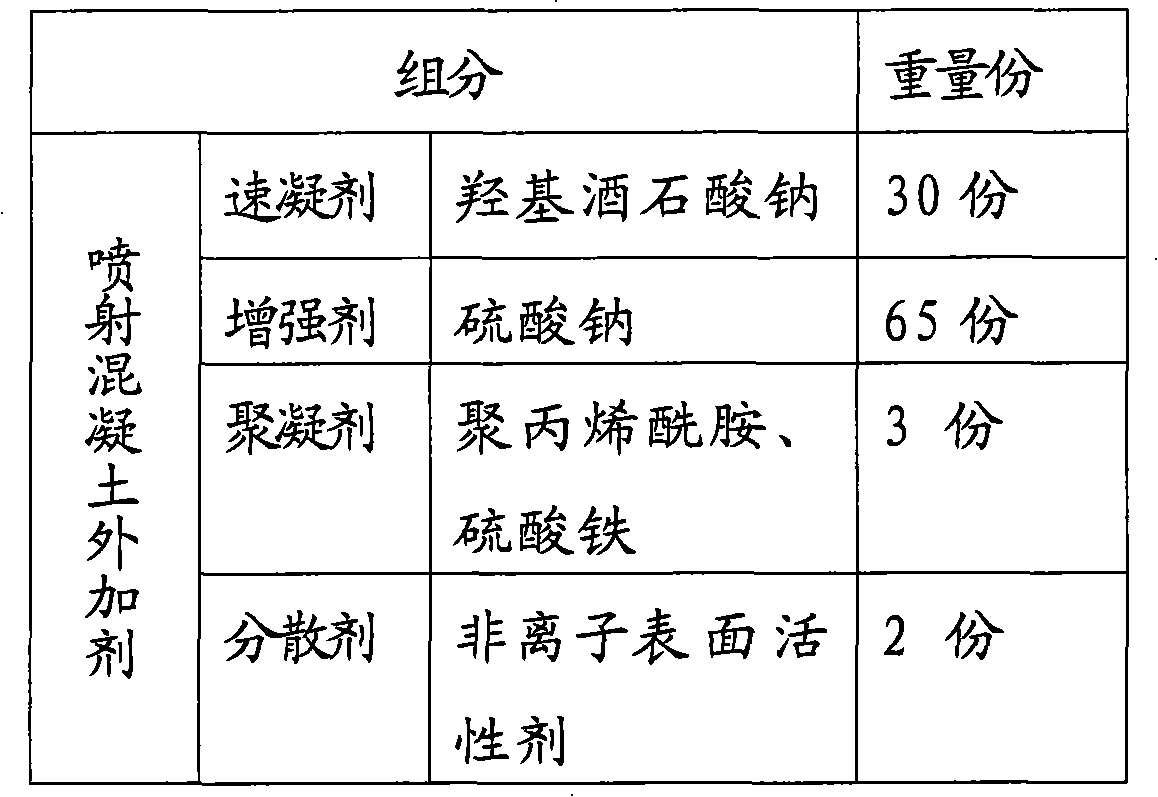

[0055] According to the spraying process of the sprayed concrete of embodiment one, wherein the composition of sprayed concrete admixture and aggregate can also be, as shown in table three:

[0056] Table three

[0057]

[0058] Wherein, the standard of the aggregate used when using the sprayed concrete admixture of this embodiment for spraying operations is: cement: P.O 42.5, stone: maximum particle size ≤ 5mm, sand: medium sand; the weight of cement, cement, and sand in the aggregate The ratio is 1: 2: 2; when the ambient temperature of the construction site is 20°C, the admixture of the shotcrete admixture is about 3% of the cement weight, and the admixture of the shotcrete admixture can be adjusted according to the environment. The decrease or increase of temperature is appropriately increased or decreased.

[0059] Specific spraying process: except that the composition of the sprayed concrete admixture in Table 1 is adjusted to the composition of Table 3, the specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com