Synchronous transmission mechanism for rolling welding machine

A technology of synchronous transmission and roll welding machine, which is applied in the direction of roller electrode welding, welding equipment, resistance welding equipment, etc., and can solve the problems of torsion bars, radial distortion of steel cage longitudinal bars, and inability to accurately synchronize the rotation of the pusher plate and the main plate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

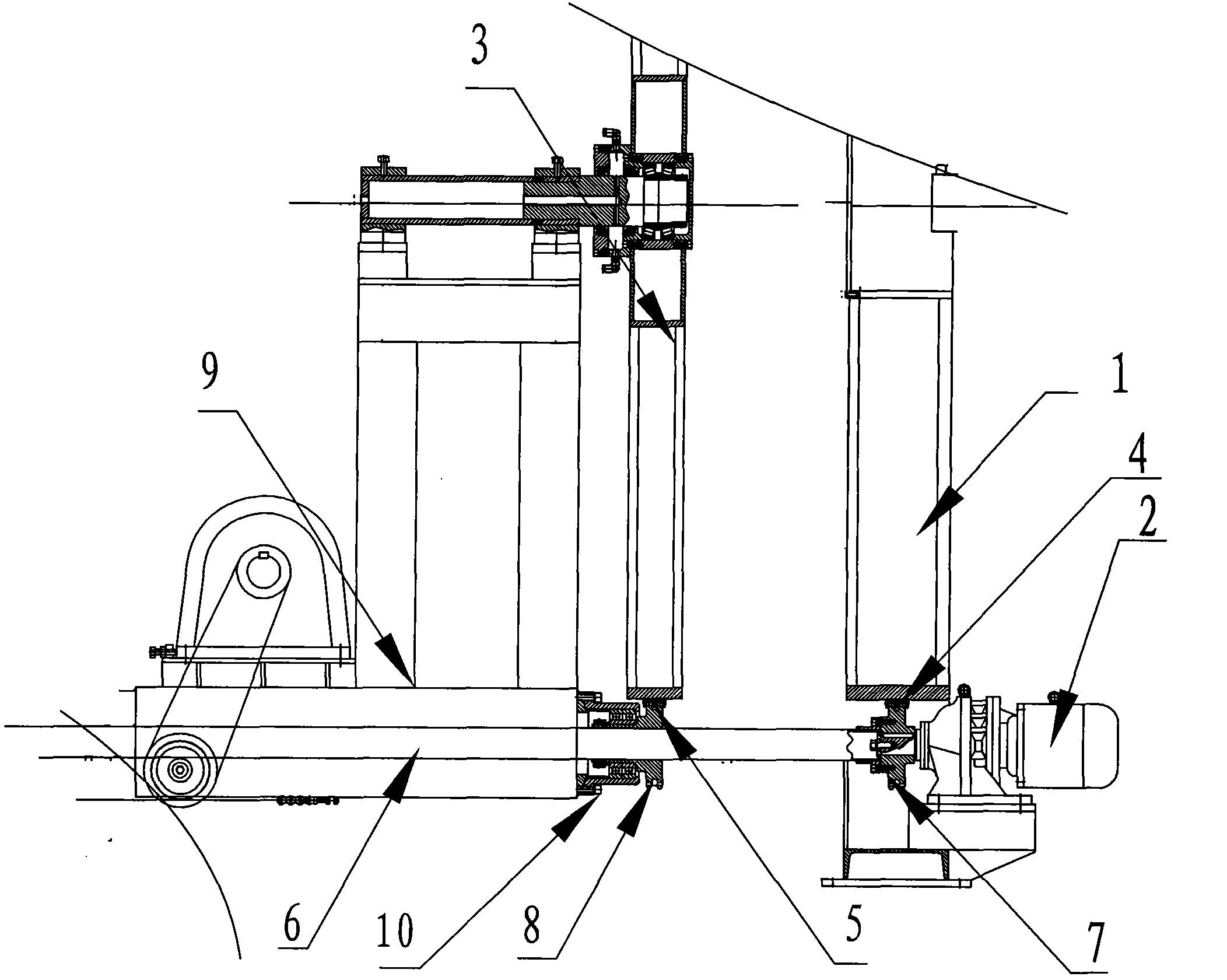

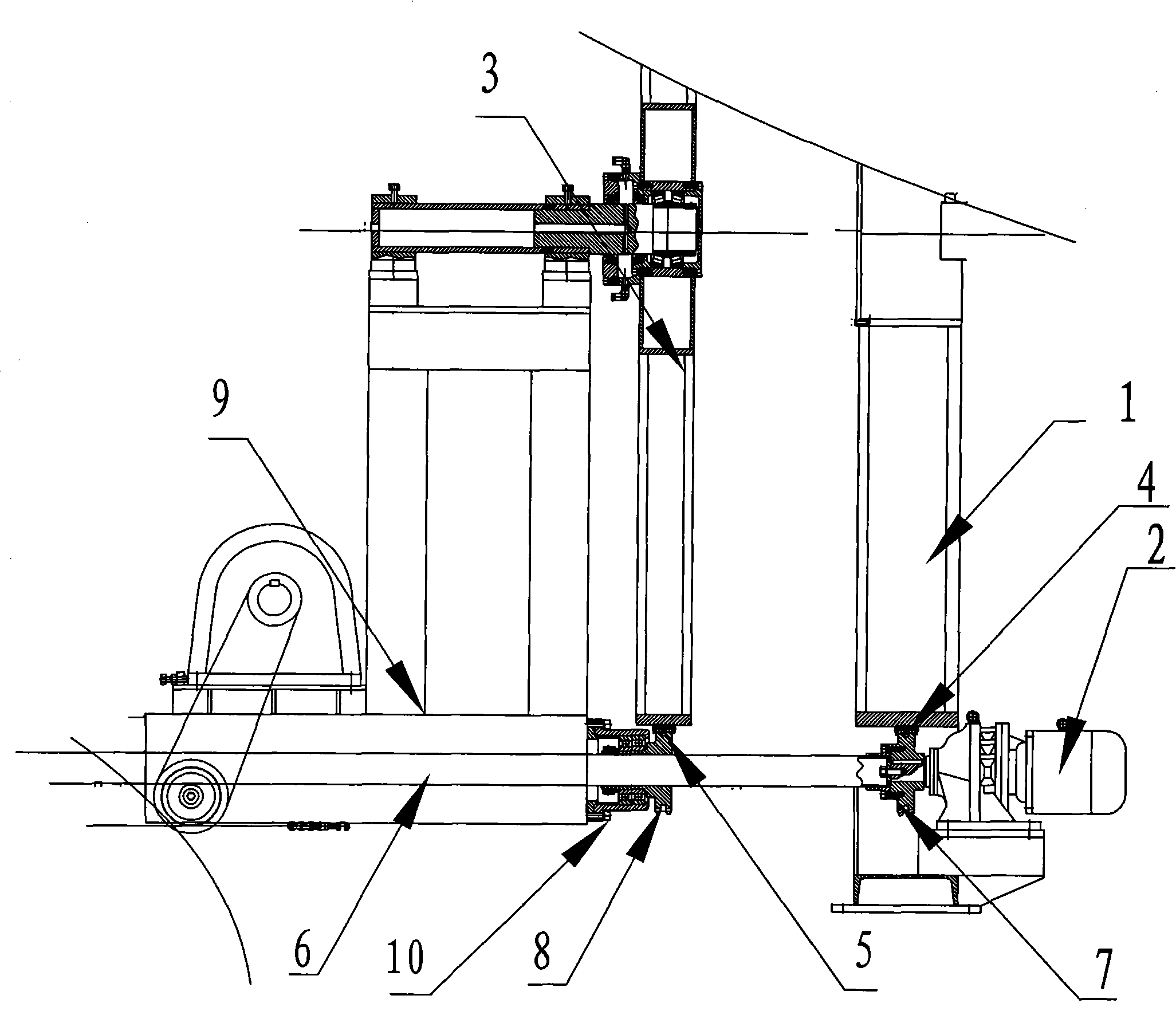

[0008] Such as figure 1 As shown, the synchronous transmission mechanism of the roll welding machine of the present invention includes a main disk 1, a power mechanism 2 and a traction faceplate 3, the rotating shaft of the traction faceplate 3 is installed on the traction trolley 9, and the main disk chain 4 is installed on the outer circumference of the main disk 1, A faceplate chain 5 is installed on the outer circumference of the traction faceplate 3, the power mechanism 2 is connected with the transmission square steel 6, and the main plate sprocket 7 and the faceplate sprocket 8 are installed on the transmission square steel 6, and the bearing seat 10 of the faceplate sprocket 8 Connected with the traction trolley 9, the faceplate sprocket 8 can slide along the transmission square steel 6 under the traction of the traction trolley 9, the main plate sprocket 7 is engaged with the main plate chain 4 for transmission, the faceplate sprocket 8 is engaged with the faceplate ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com