Optical fiber sensing device based on optical fiber bending deformation

A technology of optical fiber sensing and optical fiber, which is applied in the direction of using optical devices to transmit sensing components, measuring devices, and measuring electrical variables. problems, to achieve the effect of flexible use, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

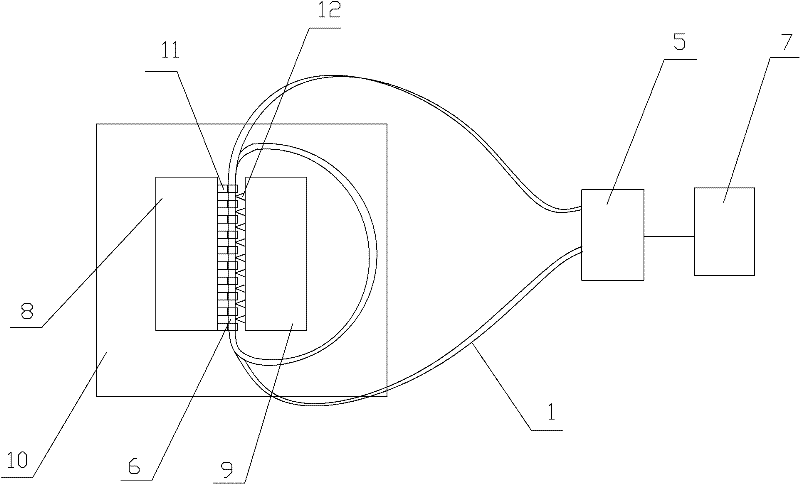

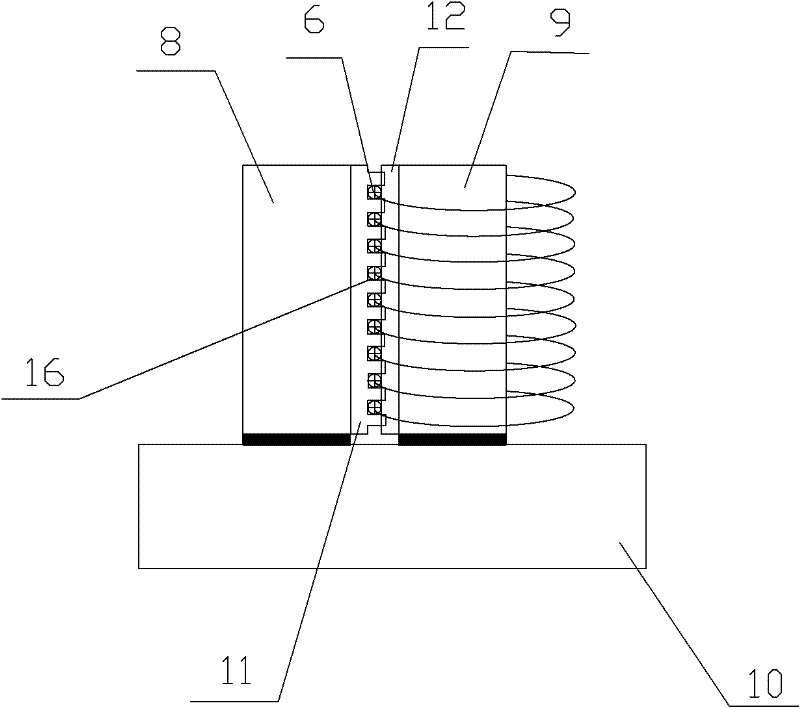

[0035] Such as figure 1 and figure 2 The shown optical fiber sensing device based on optical fiber bending deformation includes a substrate one 10, said substrate one 10, at least one of three or at least one of the first sawtooth plate 8 and the second sawtooth plate 9 arranged on the first substrate 10 A part of one of the three is made of functional materials, the first sawtooth plate 8 is provided with a deformation tooth 11, the second sawtooth plate 9 is provided with a second deformation tooth 12, and the first deformation tooth 11 and the second deformation tooth 12 are staggered and corresponding to each other. The signal optical fiber 6 is arranged on the sawtooth plate 2 9. The signal optical fiber 6 is in the shape of a multi-turn circle and is clamped between the deformation tooth 1 8 and the deformation tooth 2 9. Preferably, the sawtooth plate 2 The first plate 8 or the second sawtooth plate 9 has a groove 16 at an angle with the deformed teeth 18, and the sig...

Embodiment 2

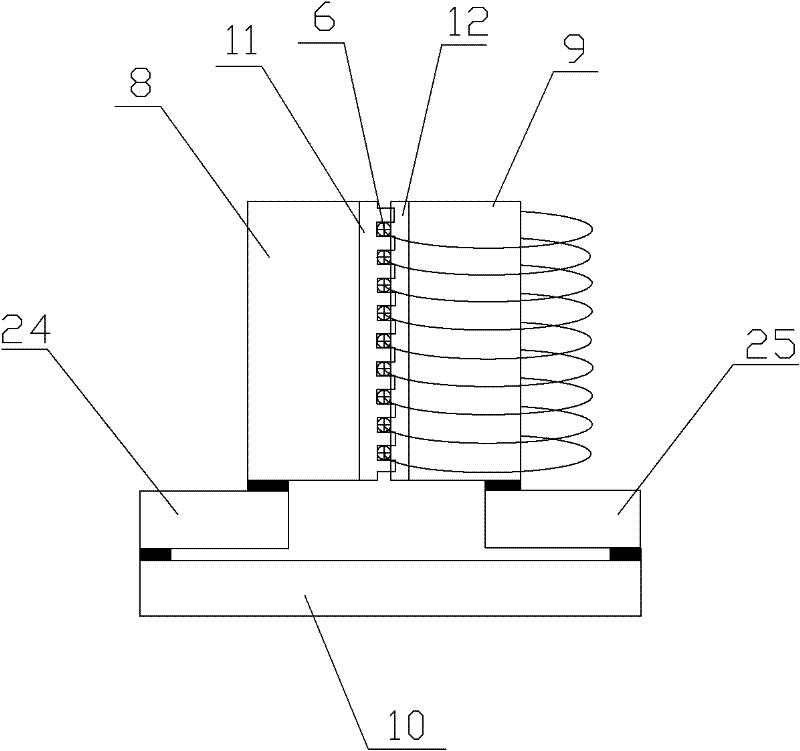

[0041] Such as image 3 As shown, the difference between the present embodiment and the first embodiment is only that the first sawtooth plate 8 and the second sawtooth plate 9 are respectively fixed on the first base plate 10 through the second base plate 24 and the third base plate 25 . The sawtooth plate one 8, sawtooth plate two 9, base plate one 10, base plate two 24, base plate three 25, deformed teeth one 11, deformed teeth two 12 and signal optical fiber 6 satisfy the following formula:

[0042] alpha 1 L 1 ΔT-α 2 L 2 ΔT-α 3 L 3 ΔT-α 齿 (L 1齿 +L 2齿 )ΔT-α 纤 d 纤 ΔT=0

[0043] Among them, α 2 and alpha 3 Respectively, the expansion coefficients of substrate two 24 and substrate three 25 materials, α 1 is the expansion coefficient of substrate-10 material, where L 2 , L 3 are the lengths of the second substrate 24 and the third substrate 25 respectively, ΔT is the changing temperature value, L 1 is the length of substrate one 10, α 齿 is the expansion coeff...

Embodiment 3

[0046] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the first deformed teeth 11 are arranged around the central point of the sawtooth plate 8 to radiate around, and the second deformed teeth 12 are arranged around the center of the sawtooth plate 9 The central point of the center is arranged in a way that the center emits to the surroundings. In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com