Engine control apparatus and method for transitioning cylinder operation modes of a multiple cylinder internal combustion engine

A technology of working mode and conversion method, which is applied in the direction of engine control, combustion engine, machine/engine, etc., and can solve the problem of different stop sequence and ignition sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

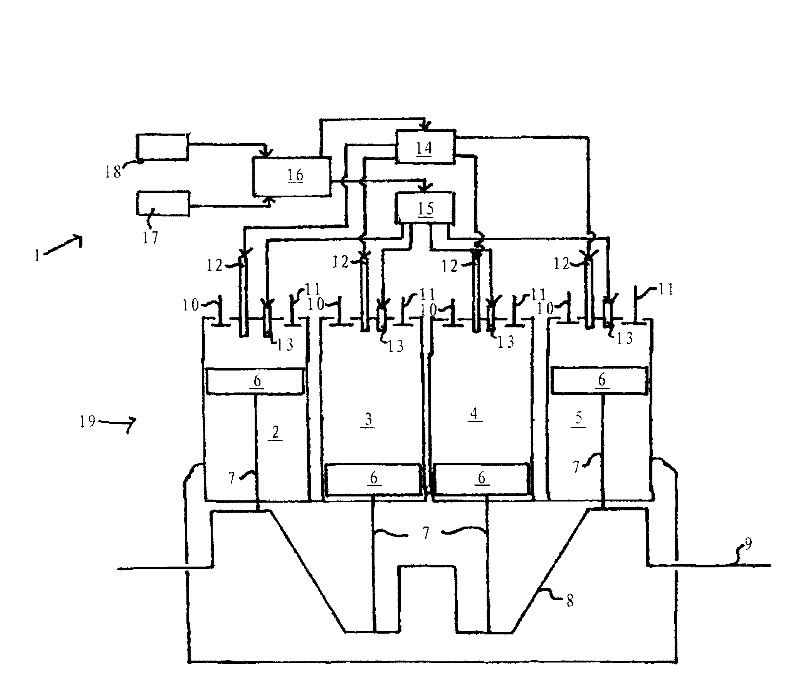

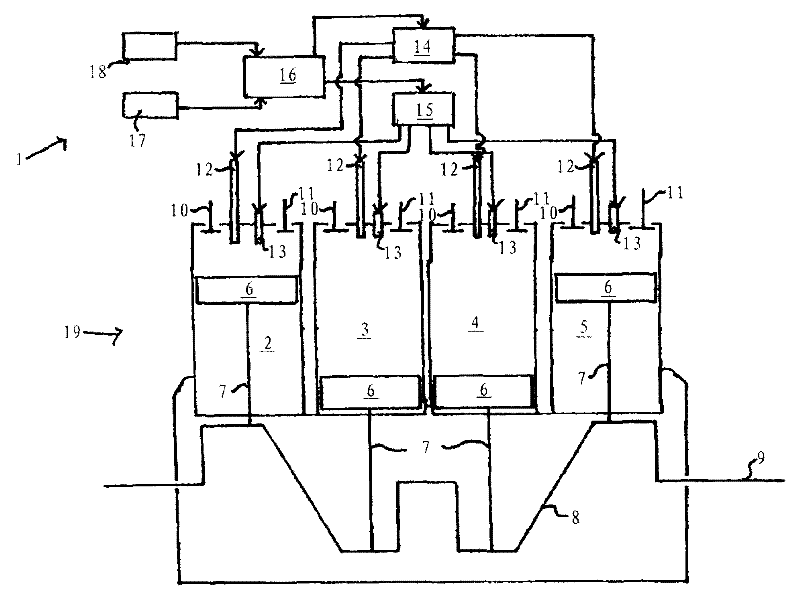

[0050] figure 1 A control device 1 for an internal combustion engine 19 is shown, which in this embodiment has four cylinders 2 , 3 , 4 , 5 arranged in a straight line as shown. Any one of the cylinders 2, 3, 4, 5 in combination with the reciprocating piston 6 provides a variable volume combustion chamber. Piston 6 is connected to crankshaft 8 by connecting rod 7 so that the reciprocating linear motion of piston 6 is converted via crankshaft 8 into rotational motion through output shaft 9 to drive a transmission of a vehicle, the vehicle and transmission not shown in the figure.

[0051]Each cylinder 2 , 3 , 4 , 5 includes an intake valve 10 , an exhaust valve 11 , a fuel injection valve 12 and a spark plug 13 . In the present embodiment, the internal combustion engine 19 is shown as a spark ignition engine.

[0052] Each fuel injection valve 12 is operated independently via a first control unit 14 and each spark plug 13 is operated independently via a second control unit 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com