Throttle manifold for controlled pressure drilling

A choke manifold and drilling technology, which is applied in the direction of earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problem of not having fluid metering, valve position detection and automatic grouting, and not being able to complete the connection of single roots. Pressure control process switching and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

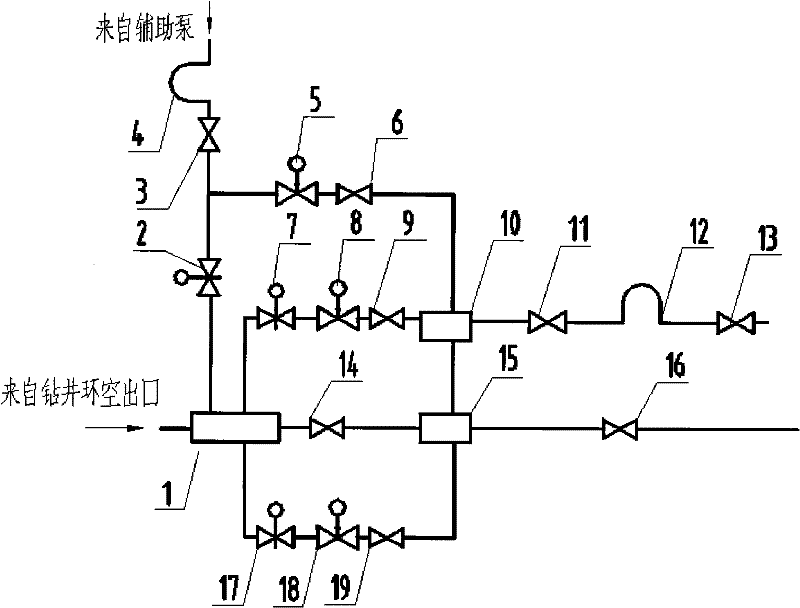

[0018] Attached below figure 1 The present invention is further described:

[0019] A choke manifold for controlled pressure drilling includes a blow-off channel, a main choke channel and an auxiliary choke channel. The discharge channel is composed of the five-way block 1, the manual flat valve 14, the four-way block 15 and the manual flat valve 16 in sequence; the main throttle channel is composed of the five-way block 1, the hydraulic flat valve 7, and the throttle valve 8 , manual plate valve 9, four-way block 10, manual plate valve 11, flowmeter 12 and manual plate valve 13 are connected by pipelines in sequence; the auxiliary throttling channel is divided into two channels by flowmeter 4 after passing through manual plate valve 3, and one channel passes through the manual plate valve 3. The hydraulic plate valve 2 is connected with the five-way block, and the other way is connected with the four-way block 10 through the throttle valve 5 and the manual plate valve 6; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com