Adsorption and separation method of C5 and C6 isomerization product

A technology of adsorption separation and isomerization, which is used in adsorption purification/separation, isomerization hydrocarbon production, organic chemistry, etc., to achieve the effect of reducing dosage and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

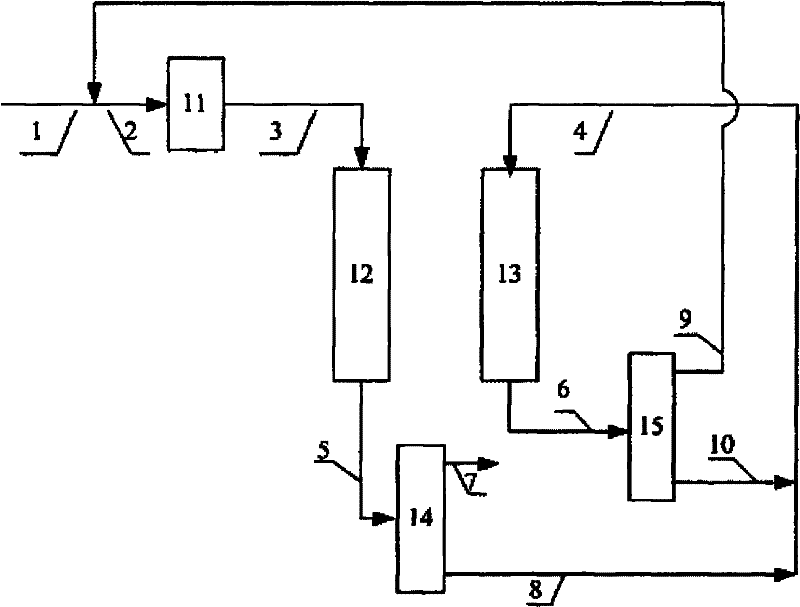

Method used

Image

Examples

example 1

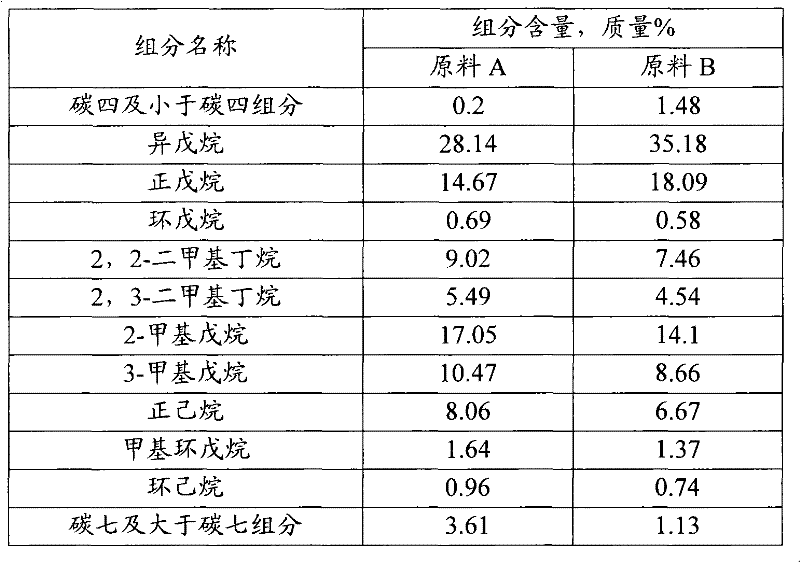

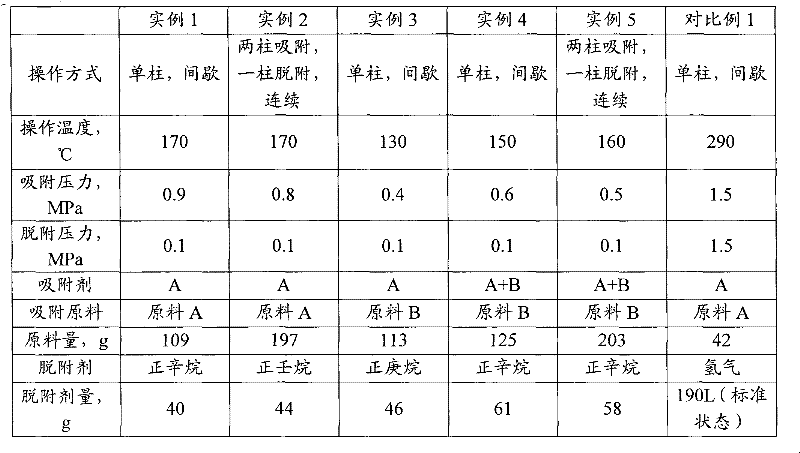

[0032] Mix ZSM-5 molecular sieve with a silica / alumina molar ratio of 25 and kaolin at a mass ratio of 90:10, roll into a ball, bake at 500°C for 4 hours, and sieve particles with a particle size of 0.3 to 0.8 mm to obtain adsorption Agent A. Pack the adsorbent A in an adsorption column with a height of 1500 mm and an inner diameter of 40 mm, and the packing mass of the adsorbent is 1413 g.

[0033] with C 5 、C 6 The alkane isomerization product is used as the adsorption raw material for adsorption separation. The raw material A whose composition is shown in Table 1 was preheated at 170°C and passed into the adsorption column from top to bottom under gas phase conditions. The pressure of the adsorption column was kept at 0.9MPa, and the temperature of the adsorption column was 170°C for adsorption and separation operation. The adsorption feed was 110 g. After the adsorption column flows out of n-pentane, n-hexane and monomethylpentane, the adsorption separation is complete...

example 2

[0035] Adsorbent A was packed in an adsorption column with a height of 1500 mm and an inner diameter of 40 mm. A total of 3 adsorption columns were filled and connected in series in sequence. The mass of adsorbent in each adsorption column was 1405 g, 1410 g, and 1413 g, respectively. Control the temperature of the adsorption column to 170°C. The raw material A preheated to 170°C is passed into the first adsorption column from top to bottom in the gas phase, and the output at the bottom enters the top of the second adsorption column, and the output at the bottom of the second adsorption column is the product of the adsorption process. The pressure of the adsorption column is 0.8MPa. After feeding 195g to the first adsorption column, feed from the top of the second adsorption column instead, and the output from the bottom of the second adsorption column enters the top of the third adsorption column, and the output from the bottom of the third adsorption column is used as the pr...

example 3

[0037] According to the method of Example 1, the adsorption material B is adsorbed and separated, and its composition is shown in Table 1. The difference is that the temperature of the adsorption column is controlled to be 130 ° C, the pressure of the adsorption column is 0.4 MPa, and after the adsorption feed is 115 g, the pressure of the adsorption column is reduced to 0.1 MPa. , modified n-heptane for desorption, the flow rate of adsorption feed and desorbent is 5g / min. 46 g of n-heptane was introduced, and the adsorption material B was introduced again, and adsorption and desorption were carried out under the aforementioned adsorption conditions. Repeated adsorption-desorption operation, adsorption separation operating conditions and adsorption methods are shown in Table 2, and the contents of each component in the output (R) of the adsorption stage and the output (E) of the desorption stage are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com