Hand-operated clamping self-lock device used for automobile instrument and clamping method thereof

A technology of automobile instrument and self-locking device, which is applied to the locking device and instrument when the movable parts of the measuring device are not in use. Drop and other problems, to achieve the effect of reliable clamping, high positioning accuracy, and rapid clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

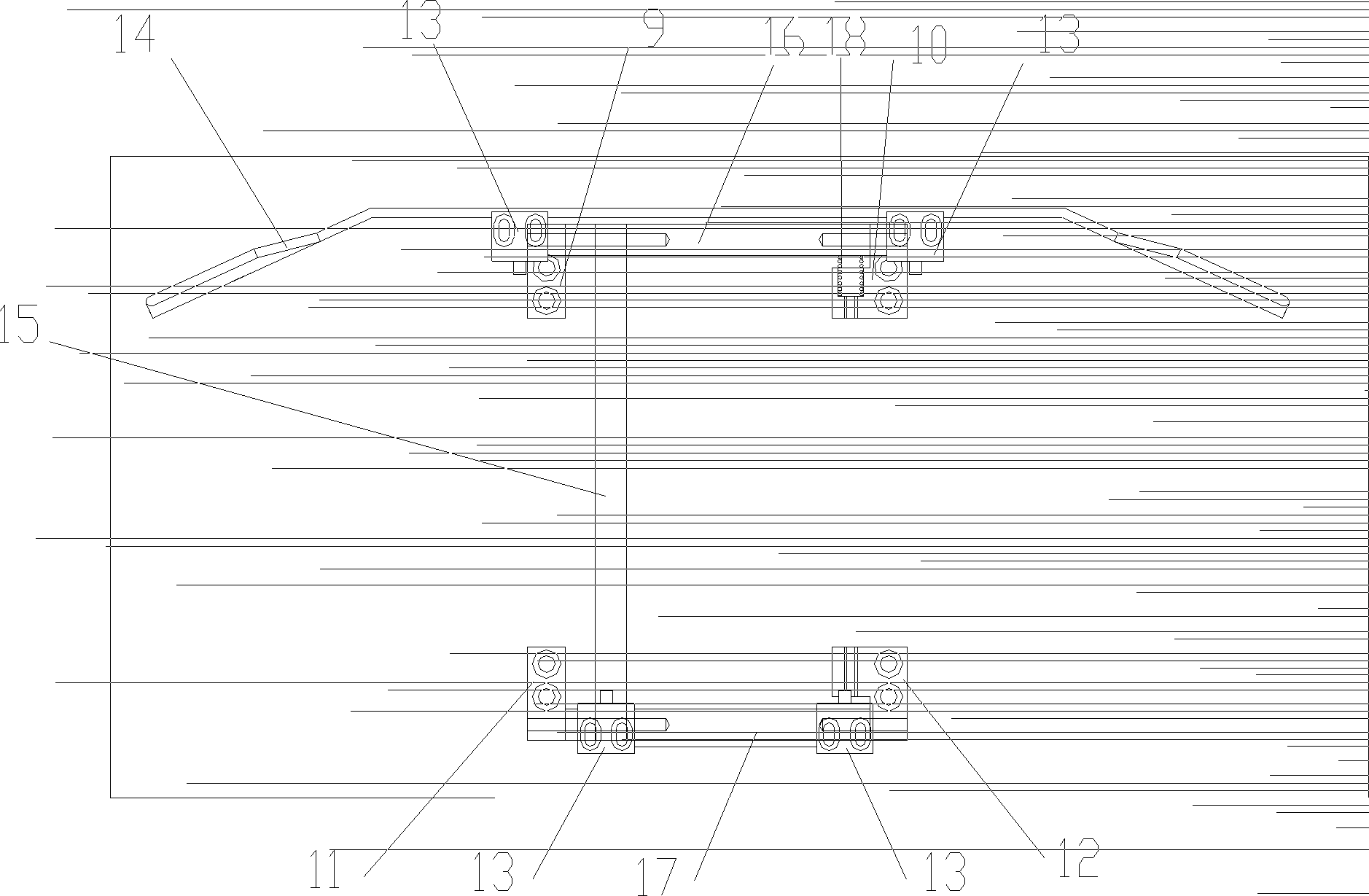

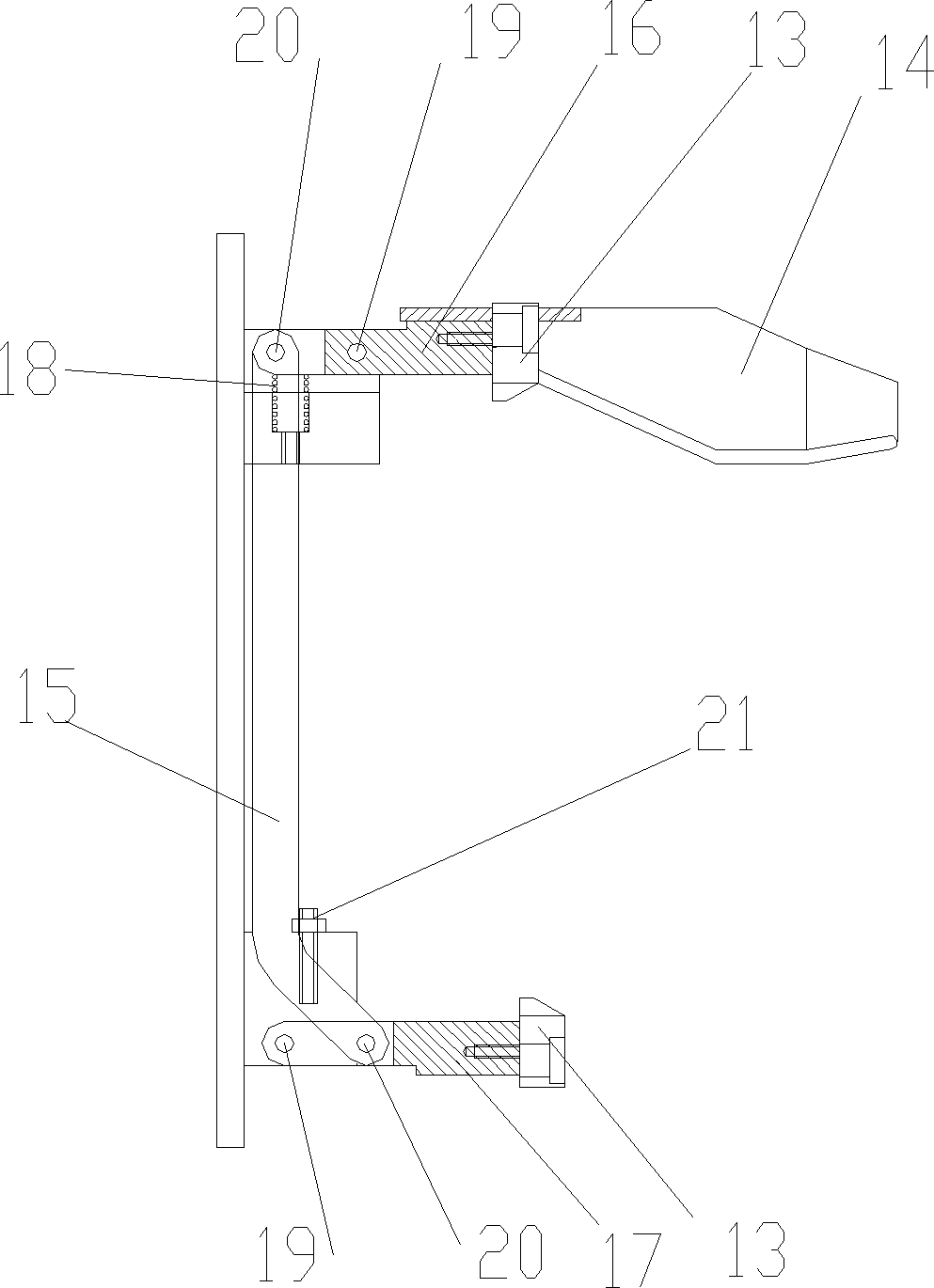

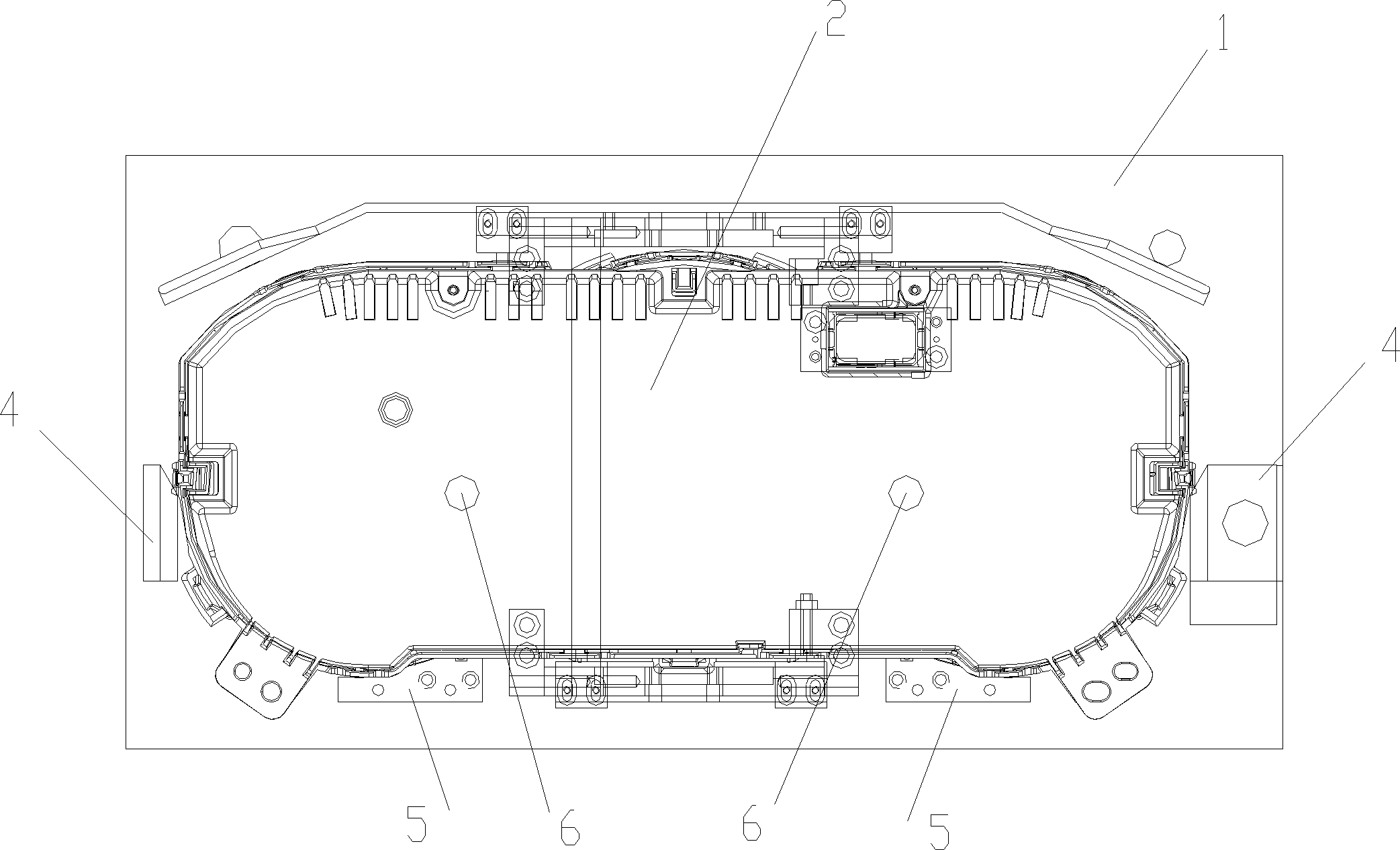

[0023] figure 1 It is a structural schematic diagram of the manual clamping self-locking device of the present invention, figure 2 for figure 1 Schematic left view of the structure shown. Depend on Figure 1-4 Combining the shown structures, it can be seen that the manual clamping and self-locking device for automobile instruments includes a test panel 1, and the top of the test panel 1 is provided with a first upper positioning block 9 and a second upper positioning block 10 located on the same horizontal line. The upper turning plate 16 is fixed between the first upper positioning block 9 and the second upper positioning block 10 by the left and right two fixed pin shafts 19, and the rotating pin shaft 20 passes through the upper connecting hole of the L-shaped connecting rod 15 to connect the L-shaped The connecting rod 15 is fixed in the groove of the upper flap 16; the test panel 1 is provided with a first lower positioning block 11 and a second lower positioning bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com