Manual oil supply lubricating pump

A technology of lubricating pump and oil supply, applied in the direction of lubricating pump, engine lubrication, lubricating parts, etc., can solve problems such as oil leakage, affecting lubrication quality, loosening of bolts, etc., to reduce costs and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

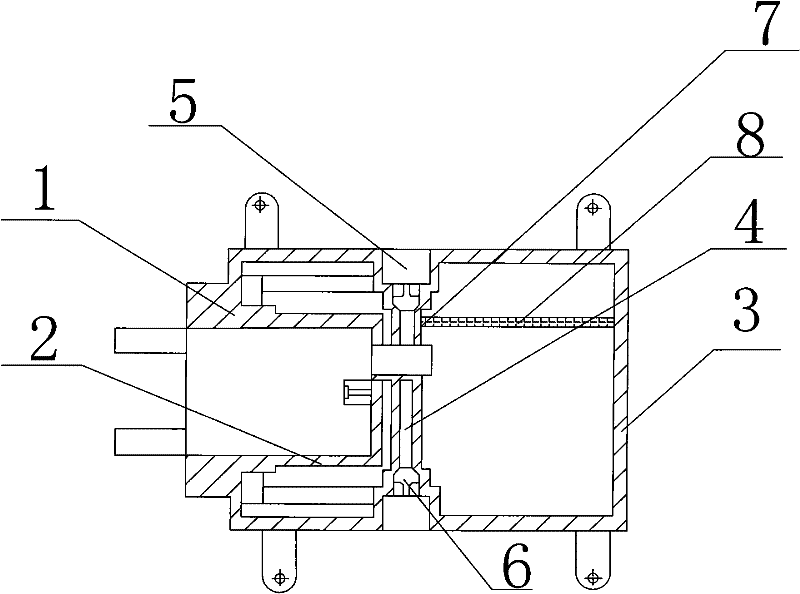

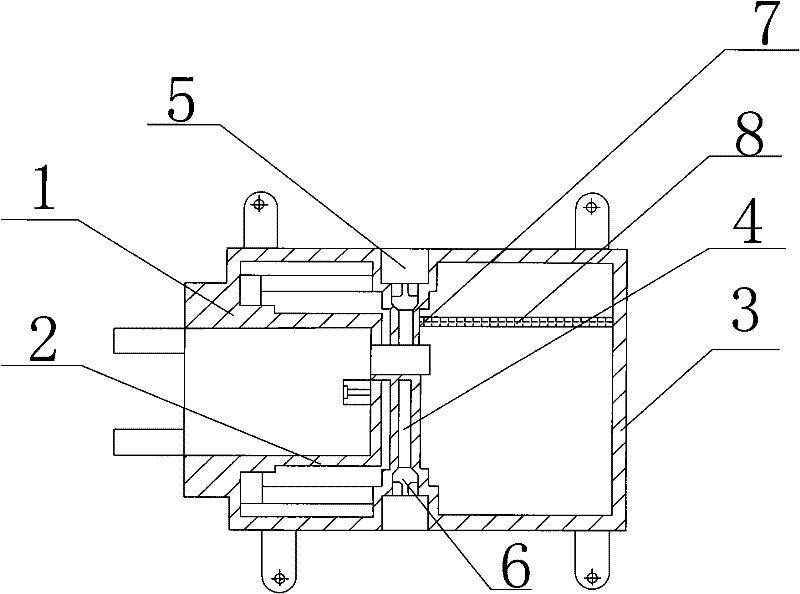

[0010] Such as figure 1 As shown, the manual oil supply lubricating pump of the present invention includes a handle bracket 1, an oil cylinder body 2, an oil tank 3 and an oil outlet cross arm 4, and one end of the oil tank 3 is provided with an oil outlet 5, and the oil outlet 5 communicates with mechanical equipment through a pipeline , the oil outlet 5 is provided with a one-way valve 6 to prevent oil backflow in the pipeline, the handle bracket 1, the oil cylinder body 2, the oil outlet cross arm 4, and the oil tank 3 are integrally formed, and the oil tank 3 is provided with an oil A filter device 7, the oil filter device 7 is a filter screen 8.

[0011] In the present invention, the handle bracket 1, the oil cylinder body 2, the oil outlet cross arm 4 and the oil tank 3 are molded at one time on the aluminum casting machine, and the parts are combined together so that there is no gap between the parts of the whole manual oil supply lubrication pump, so There will be no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com