Cast-in-place concrete structure suspension scaffolding

A concrete structure and scaffolding technology, which is applied in the direction of scaffolding for building structure support, building structure support, building structure support, etc., can solve the problems of difficulty in building and dismantling, unsafe, uneconomical, etc., and achieve light weight, convenient building and dismantling, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

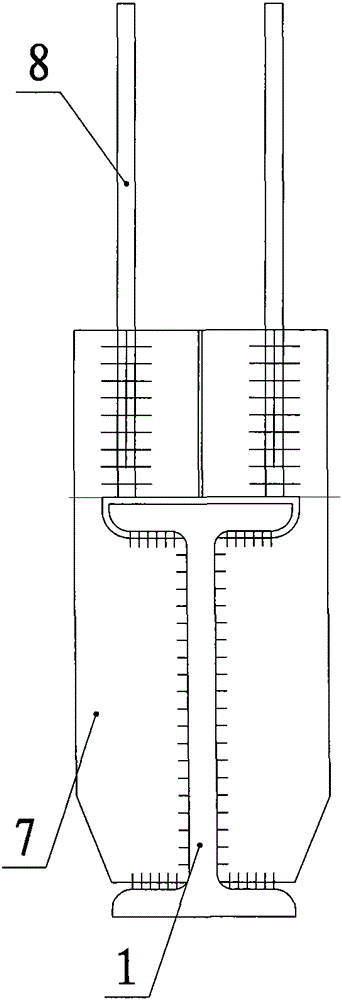

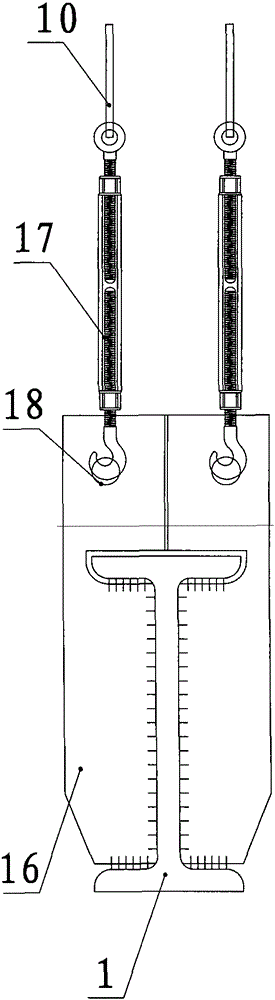

[0022] Example: see figure 1 , a suspension scaffolding of cast-in-situ concrete structure in the figure, including cantilevered steel beams, scaffolding boards laid on the cantilevered steel beams, full hall scaffolding, formwork components, said cantilevered steel beams are several, fixed by anchors On the solidified floor of the lower floor of the pre-cast floor slab, the scaffolding is laid on the surface of the cantilevered steel beam, the full scaffolding is set up on the upper part of the scaffolding, and a formwork assembly is arranged on the part of the full scaffolding extending out of the floor; The part where the cantilevered steel beam protrudes from the floor slab is provided with a diagonal tie rod to connect with the anchor hanger on the edge of the upper floor slab; The anchor rings on the edge of the floor slab are connected to form a safety device; the inner end of the cantilevered steel beam is provided with an anti-slip device, and the anti-slip device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com