Method and system for conveying solvent and equipment using the system

A solvent and equipment technology, applied in the field of beverage preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

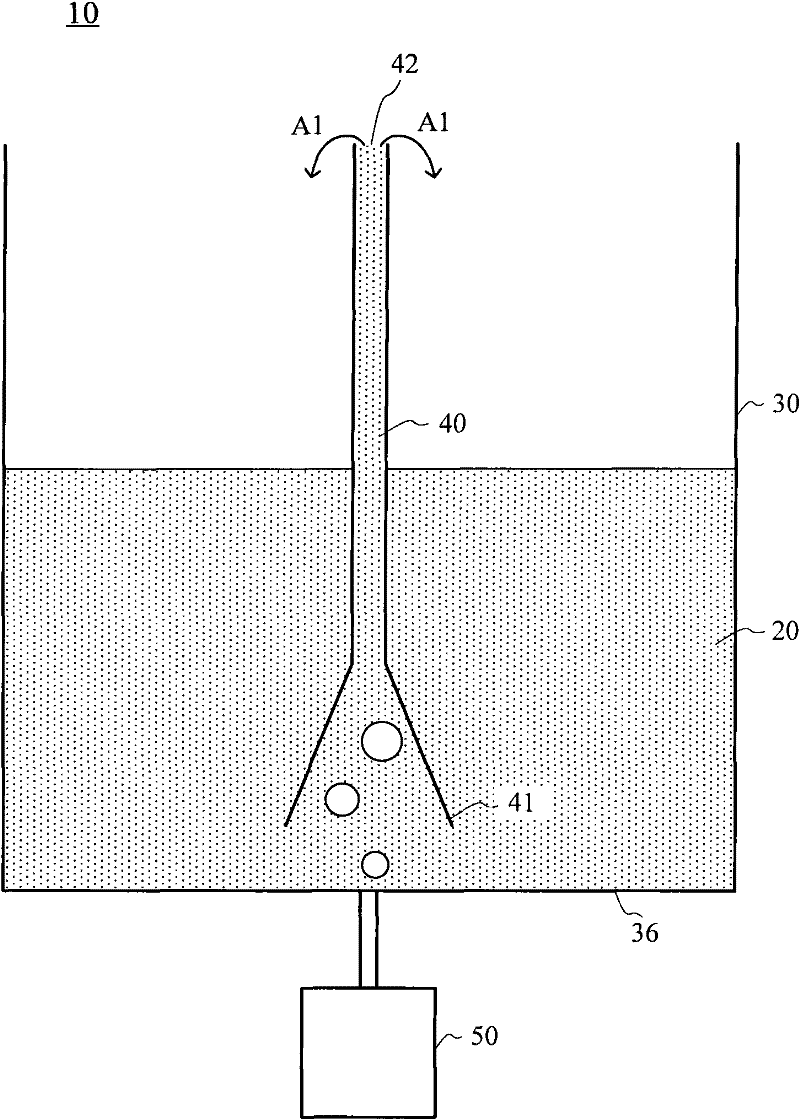

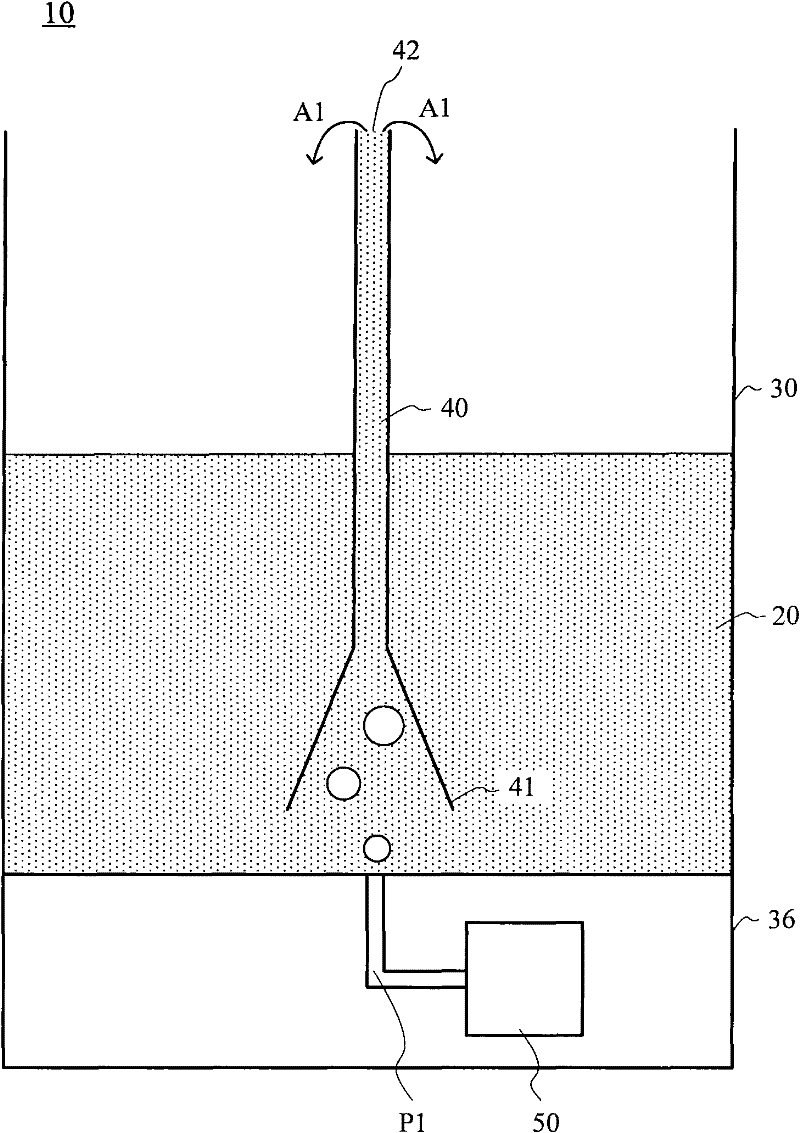

[0039] figure 1 A system for delivering a solvent according to one embodiment of the invention is shown. In this embodiment, system 10 for delivering solvent 20 includes container 30 , tubing 40 and air pump 50 .

[0040] The container 30 is used to contain the solvent 20 .

[0041] The tube 40 is located in the container 30 and has a first end 41 located near the bottom portion 36 of the container 30 and a second end 42 reaching the upper portion of the container 30 .

[0042] The air pump 50 is used to generate the gas flow discharged from the bottom part of the container 30, so that at least part of the gas flow can enter the tube 40 at the first end 41 to transport the solvent 20 in the tube 40 from the first end 41 to the second end 42, This is shown by arrow A1 at the second end 42 . Air flow is shown by the white circles in the solution 20 below the first end 41 . Air pump 50 may be of any type, preferably as image 3 Described diaphragm air pump.

[0043]It will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com