Continuous coagulating device for soybean curds

A technology of tofu and coagulant, applied in the fields of application, food preparation, food science, etc., can solve problems such as difficulty in raising, leakage of soybean milk, unhygienic, etc., and achieve the effect of preventing and suppressing twists and turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

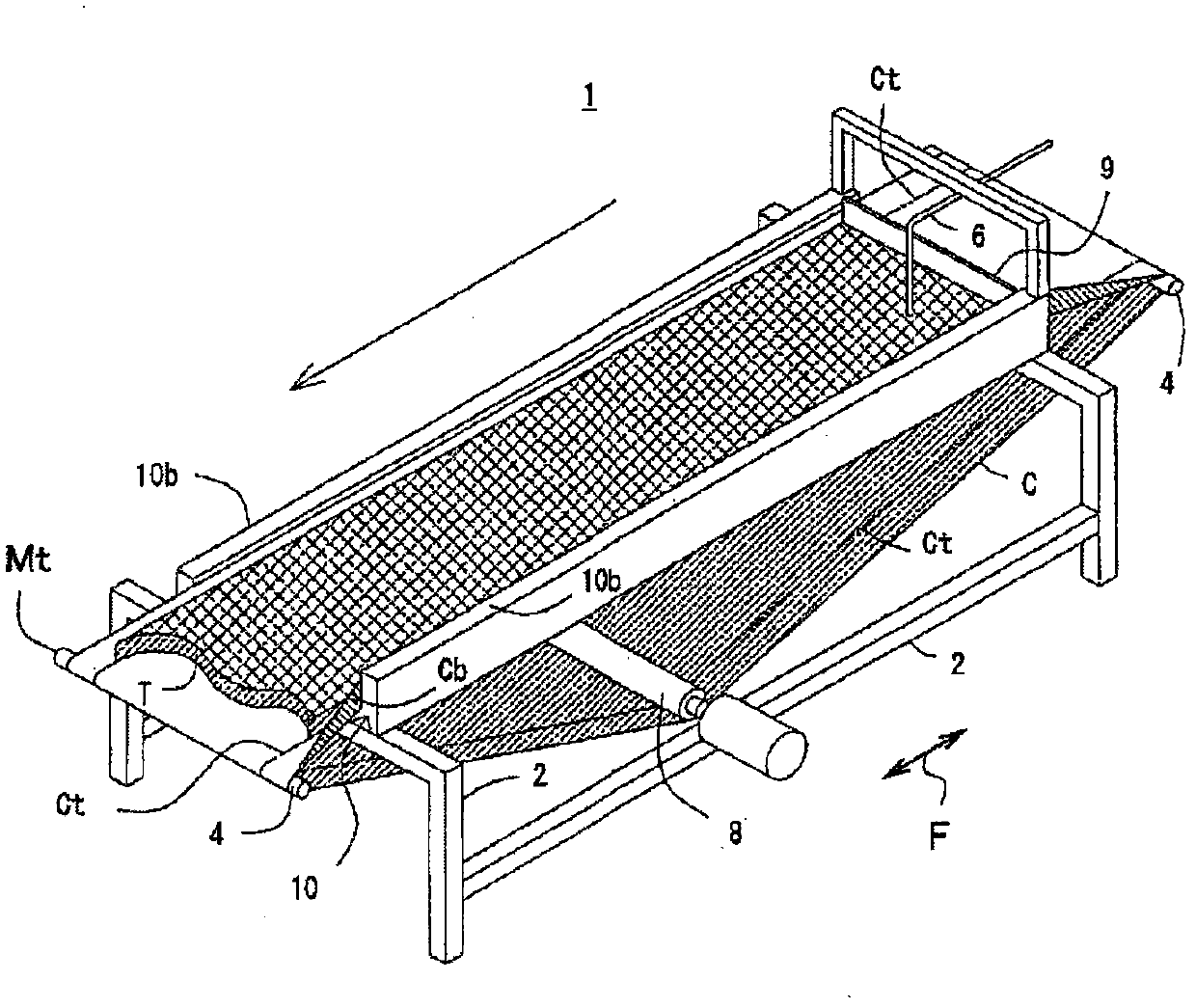

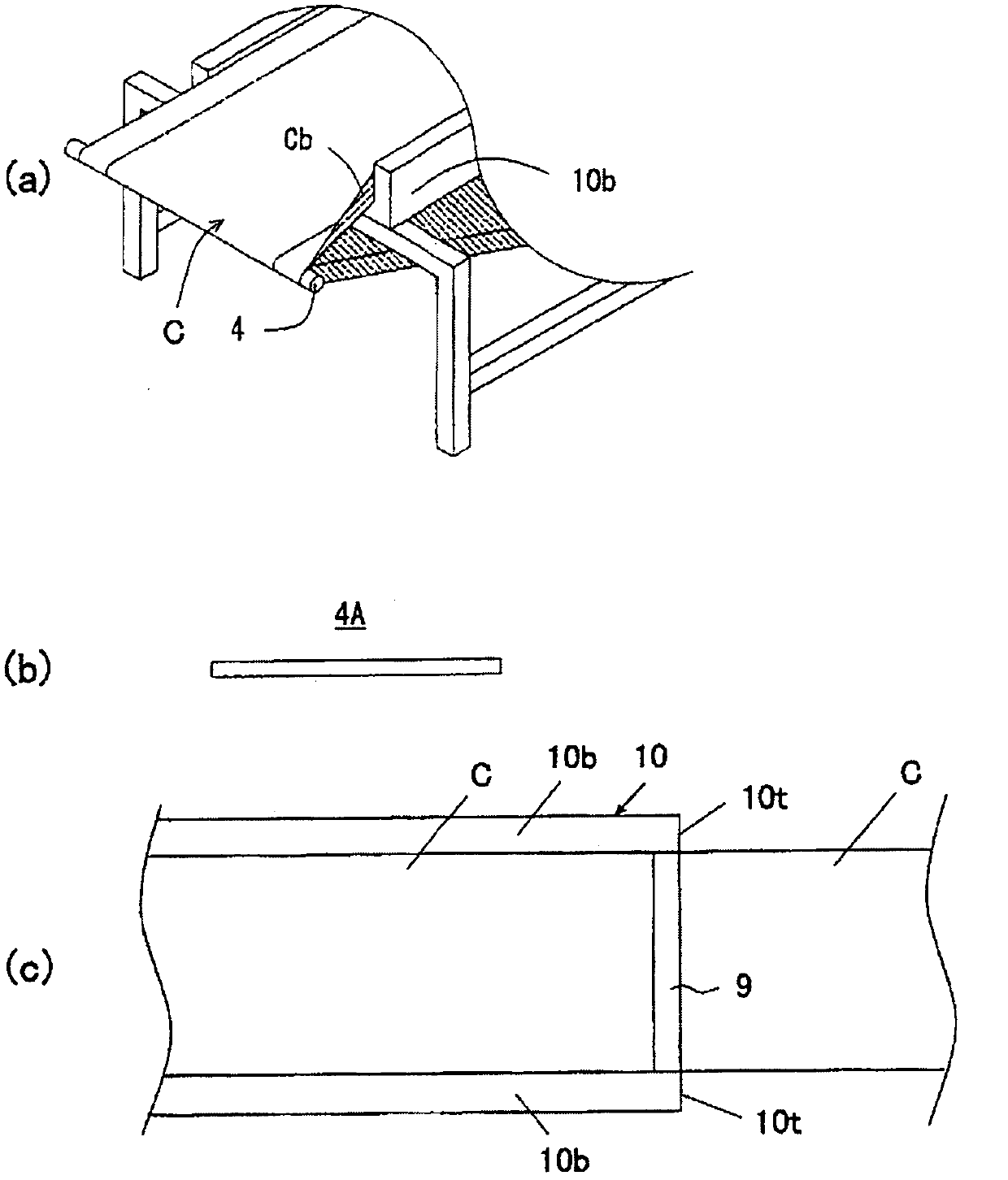

[0052] Hereinafter, specific embodiments to which the present invention is applied will be described in detail with reference to the drawings.

[0053] This embodiment is as Figure 1 to Figure 4 Shown is a continuous solidification device for tofu including: a concave member 10 disposed above the base 2; and a conveyor belt C driven along the longitudinal direction of the base 2. In addition, the sheet (ribbon) tofu T coagulated by the continuous coagulation device 1 for tofu is not broken in the case of fine tofu or soft tofu filtered with silk, and is not broken in the case of kapok tofu and light fried tofu cubes. ,Such as Figure 12 and Figure 13 As shown, it is crushed by the crushing device Mi, and transported to the next molding machine 21, 22 or a cutting and distributing device and a packing device not shown.

[0054] The base 2 is made of steel or stainless steel with legs at the front and rear, and the concave member 10 is arranged above it, and the driving sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com