Integrated wire protection component

An integrated, wire-protecting technology, applied in electrical components, parts of connecting devices, bases/shells, etc., can solve problems such as shortening the service life of wires and connectors, poor sealing effect, damage to equipment, etc., to avoid salt Fog corrosion, easy maintenance and replacement, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

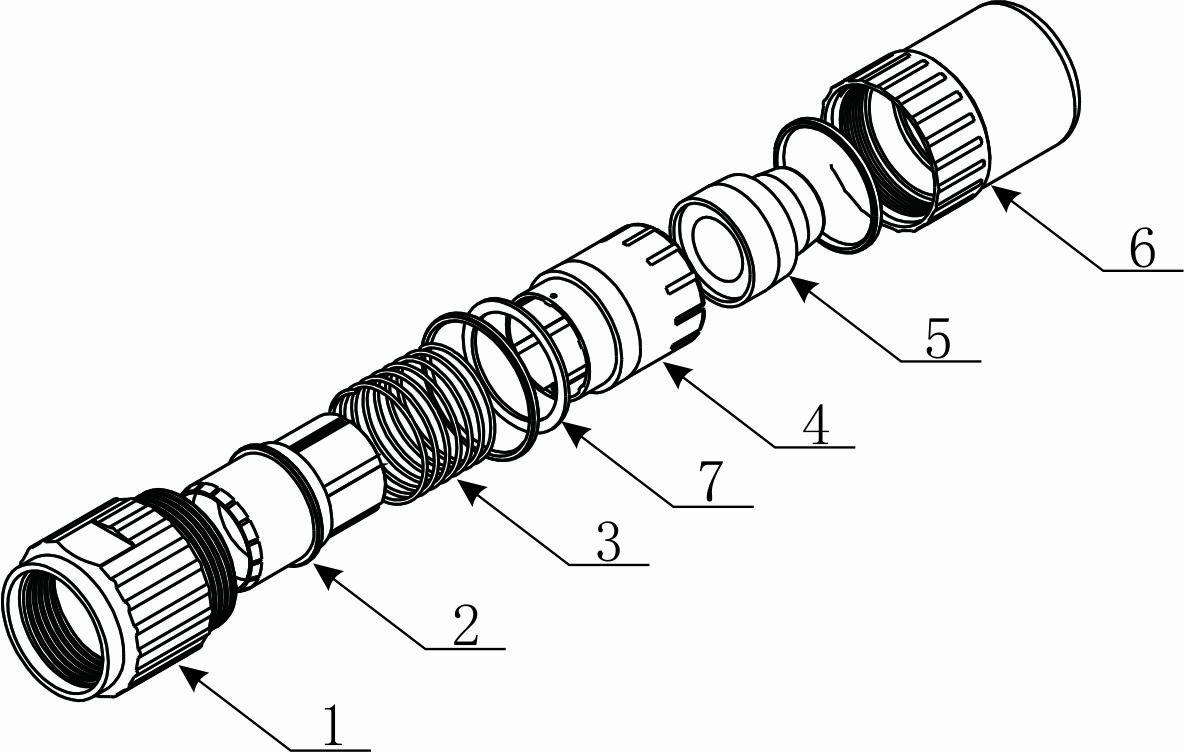

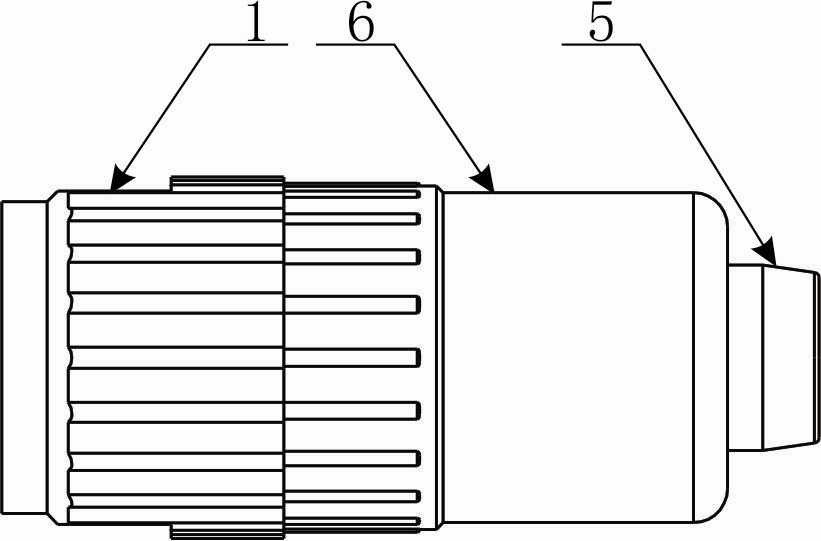

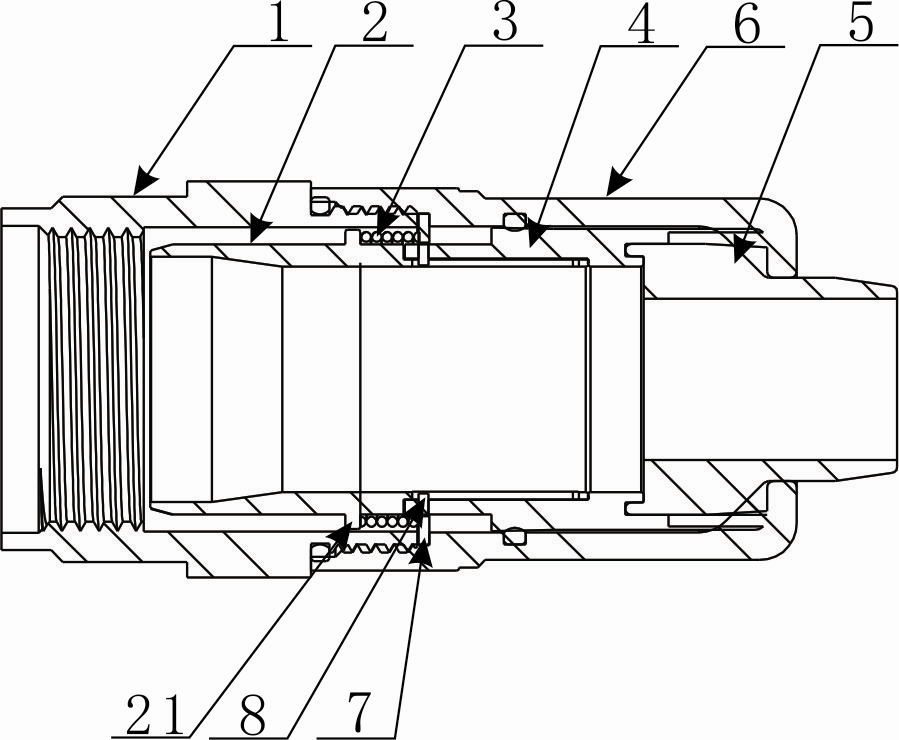

[0049] An integral grommet assembly connects the shielded conductor to the plug.

[0050]When in use, the staff only need to put the wire into the integrated wire protection assembly, peel off the enameled wire on the wire, and stretch the shielding layer; insert the metal wire into the corresponding position of the plug, and connect the plug with the head of the integrated wire protection assembly. The external packaging component 1 is screwed tightly. While tightening, the bushing 2 moves inward, and the shielding layer is stuck between the chamfer of the head of the bushing 2 and the inner chamfer of the plug, and the groove of the chamfered part of the head of the bushing 2 is in contact with the inner side of the plug. The bumps on the chamfered part make the wire shielding layer and the bushing 2 unable to rotate to prevent the wire from twisting; It is arranged between the protruding ring 21 of the bushing 2 and the washer 7, so that the bushing 2 and the claw 4 cannot...

Embodiment 2

[0053] The one-piece grommet assembly connects the unshielded conductor to the plug.

[0054] When in use, the staff only need to put the wire into the integrated wire protection assembly, strip the enameled wire on the wire; insert the metal wire into the corresponding position of the plug, and screw the plug and the head packaging element 1 of the integrated wire protection assembly . While tightening, the chamfer of the head of the bush 2 is closely matched with the inner chamfer of the plug, and the bush 2 moves inward; when the pin 8 set at the bottom of the first layer of the claw 4 moves into the groove 23 of the bush 2 After the left side, because the spring 3 is set between the collar 21 of the bushing 2 and the washer 7, the bushing 2 and the claw 4 can no longer move forward; Can not rotate, at this time, the claw head 42 of the claw 4 is deformed under force, and the wire sealing body 5 is subjected to the radial force of the claw head 42 of the claw 4, and tightl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com