Qualitative detection method for EKS fibers

A qualitative detection, fiber technology, applied in the direction of color/spectral characteristic measurement, measuring device, material inspection product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Such as figure 1 Shown, a kind of qualitative detection method of EKS fiber, comprises following sequential steps:

[0037] (1) Combustion detection: Burn the fiber with a flame, and identify the fiber according to the state of the fiber when it is close to the flame, when it is in contact with the flame, and when it leaves the flame, as well as the color during burning and the characteristics of the residue after burning. If the fiber does not melt or shrink when it is close to the flame , when it burns in the flame, it is slow burning and emits white smoke, and it is self-extinguishing when it leaves the flame, and the residue is a thin and soft black floc, then it may be judged to be EKS fiber, and proceed to the next step; otherwise, it is not EKS fiber , the detection ends;

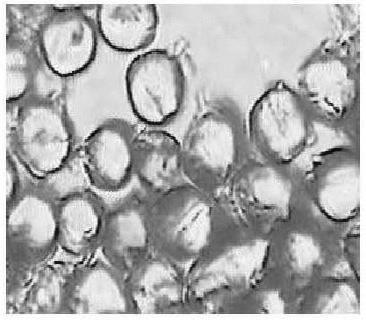

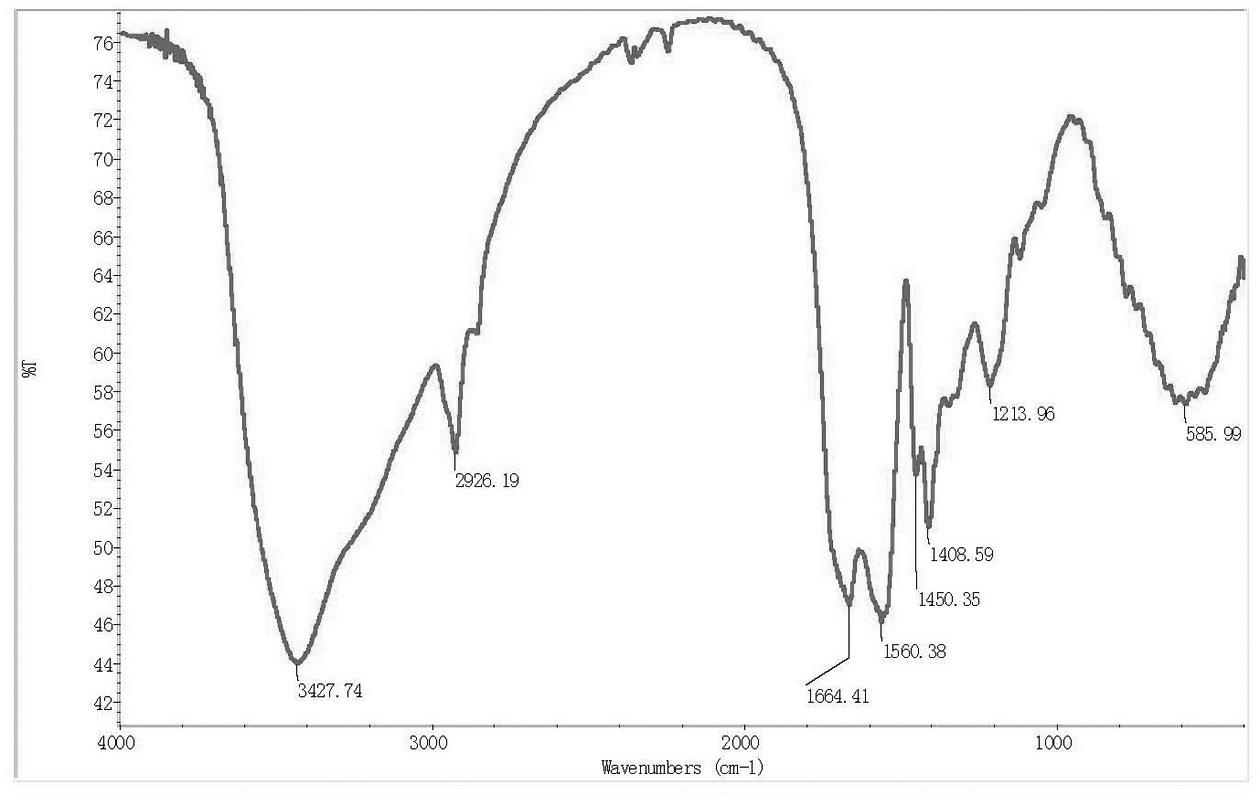

[0038] (2) Microscopic examination:

[0039] Longitudinal slice preparation: Embed an appropriate amount of fiber in the groove of a Hastelloy slicer, cut a certain length of fiber and extra...

Embodiment 2

[0052] Such as figure 1 Shown, a kind of qualitative detection method of EKS fiber, comprises following sequential steps:

[0053] (1) Combustion detection: Burn the fiber with a flame, and identify the fiber according to the state of the fiber when it is close to the flame, when it is in contact with the flame, and when it leaves the flame, as well as the color during burning and the characteristics of the residue after burning. If the fiber does not melt or shrink when it is close to the flame , when it burns in the flame, it is slow burning and emits white smoke, and it is self-extinguishing when it leaves the flame, and the residue is a thin and soft black floc, then it may be judged to be EKS fiber, and proceed to the next step; otherwise, it is not EKS fiber , the detection ends;

[0054] (2) Microscopic examination:

[0055] Longitudinal slice preparation: Embed an appropriate amount of fiber in the groove of a Hastelloy slicer, cut a certain length of fiber and extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com