Integrated machine set for cooling milk

An integrated, milky technology, applied in the field of cooling units, can solve the problems of increasing equipment footprint, increasing equipment purchase costs, troublesome maintenance, etc., to achieve the effect of saving land space, reducing costs, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

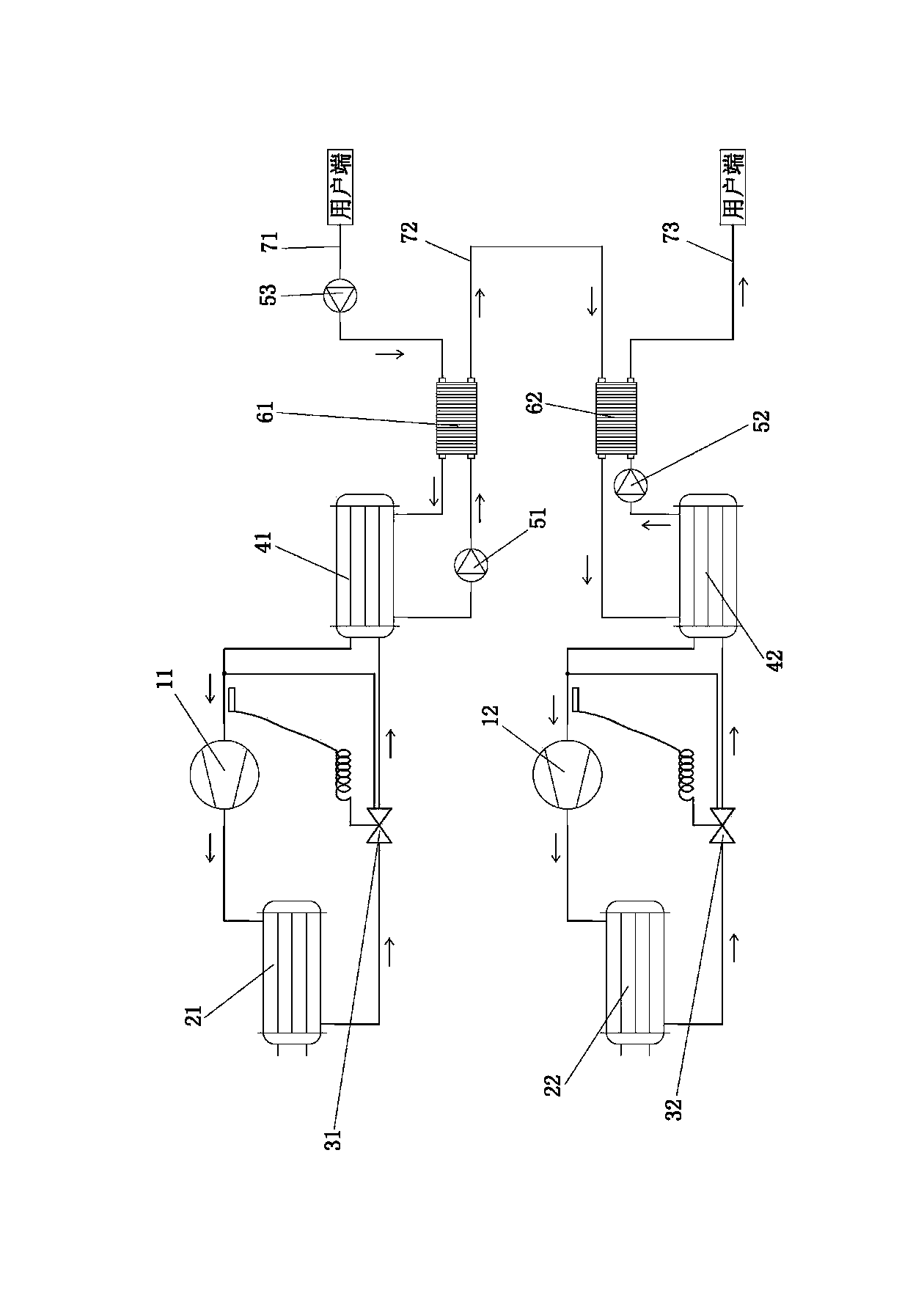

[0012] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the accompanying drawings.

[0013] As attached figure 1 As shown, a milk cooling integrated unit includes a first refrigeration cycle composed of a first compressor 11, a first condenser 21, a first expansion valve 31, and a first evaporator 41 that are circulated in sequence through pipelines, And a second refrigeration cycle circuit composed of a second compressor 12, a second condenser 22, a second expansion valve 32, and a second evaporator 42 that are sequentially circulated and communicated through pipelines. A circulating water system and a third circulating water system are connected; the second refrigeration cycle is connected to the second circulating water system and the third circulating water system in sequence.

[0014] The first circulating water system is composed of a first water pump 51, a first heat exchanger 61, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com