Rolling and sliding bearing with outer ring as sleeve

A kind of rolling bearing and outer ring technology, applied in rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of poor axial accuracy, inability to install rollers or sliders, etc., and achieve long service life and installation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

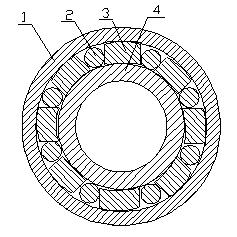

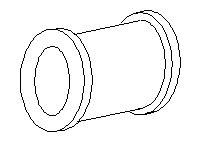

[0032] The present invention will be further described through an embodiment in which both ends of the rolling bearing have fixed ribs.

[0033] This embodiment: the inner ring is a part with fixed ribs at both ends, and the outer ring is a kit with fixed ribs at both ends to realize the purpose of fixed ribs at both ends of the inner and outer rings of the rolling bearing; the structure of the rolling bearing see figure 1 , the inner ring structure see figure 2 , see the structure of the outer ring image 3 and Figure 4 ;The outer ring is composed of an external thread ring 5 without ribs, an open spring gasket 6, an inner thread ring 7 at the left rib of the outer ring and an inner thread ring 8 at the right rib of the outer ring; an outer thread ring 5 without ribs and a left rib Internally threaded circle 7, right rib internally threaded circle 8 are connected by thread. The relationship between the split spring washer 6 and the non-wall external thread circle 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com