Gas drainage drill hole structure formed in coal layer and method for fabricating same

A technology of gas drainage and production method, which is applied in the direction of gas drainage, earthwork drilling, safety devices, etc., and can solve the problems of on-site construction personnel's personal safety threat, gas drainage drilling leakage, and affecting the stability of coal walls, etc. To achieve the effect of reducing accidents caused by coal wall fragments, reducing gas leakage, and improving gas drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The method for forming a gas drainage borehole in a coal seam according to the present invention will be described in detail below with reference to the accompanying drawings and examples.

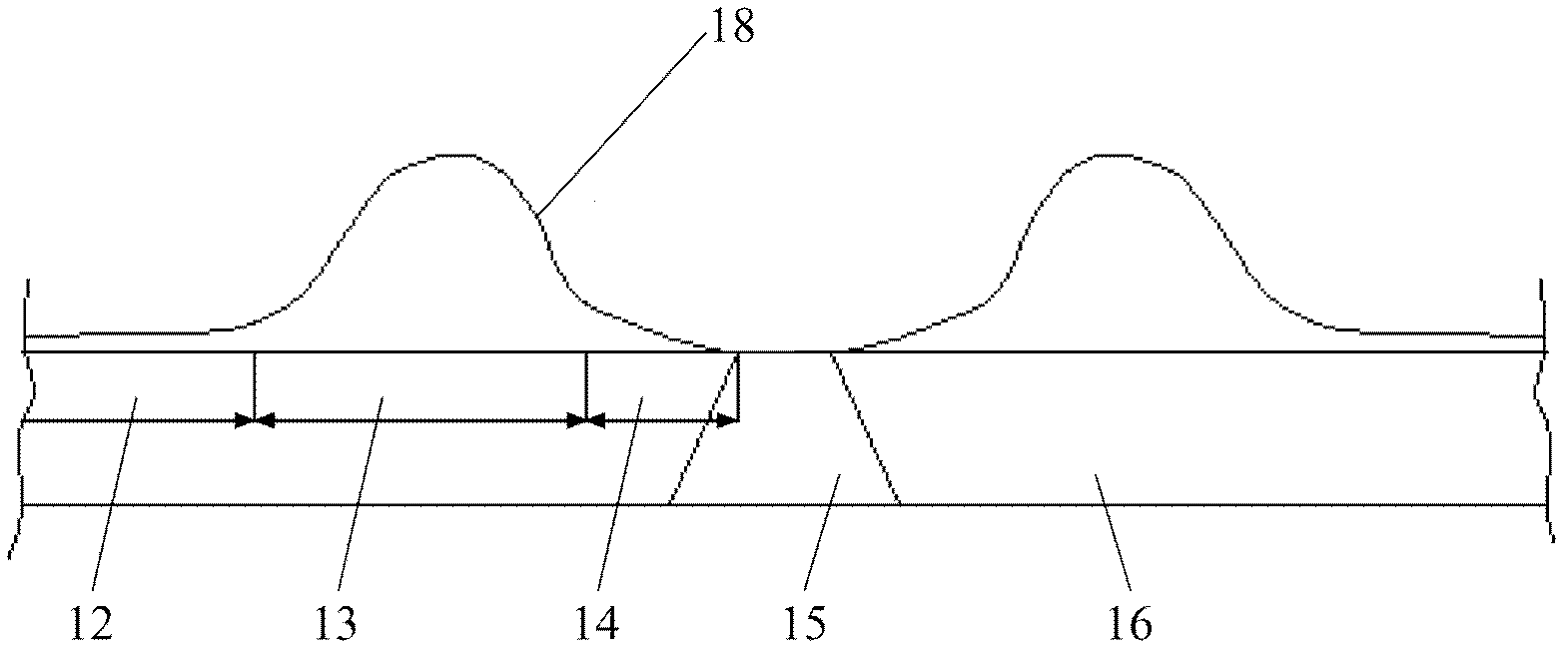

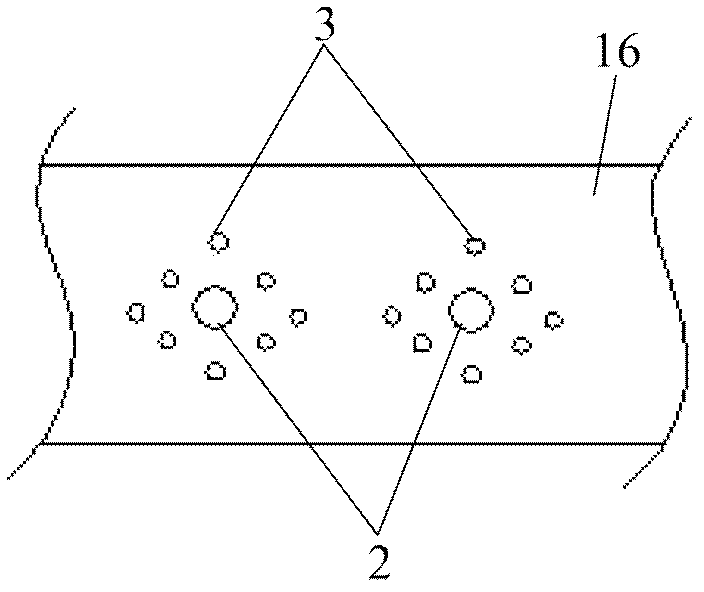

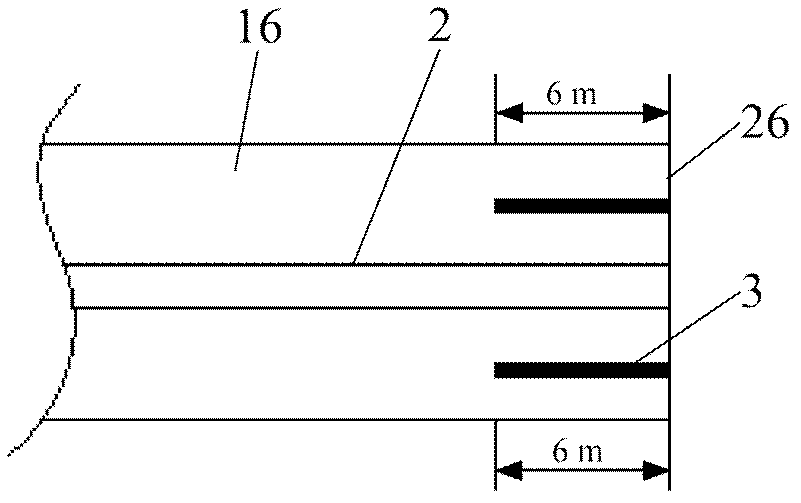

[0036] figure 1 It is a schematic diagram showing the stress curve 18 of the two sides of the coal roadway during the driving process of the coal roadway. Such as figure 1 As shown, during the tunneling process of the coal roadway, the original stress balance of the coal seam 12 is destroyed, and a three-dimensional structure including the pressure relief zone 14, the stress concentration zone 13 and the original stress zone 12 is formed in front of the coal walls of the two sides of the coal roadway. A stress zone, wherein, the width of the pressure relief zone 14 extends inwardly from the coal walls of the two sides of the coal roadway 15 approximately by 5-7m. In this area, the coal seam 16 will expand under the action of the concentrated stress in front of the working face. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com