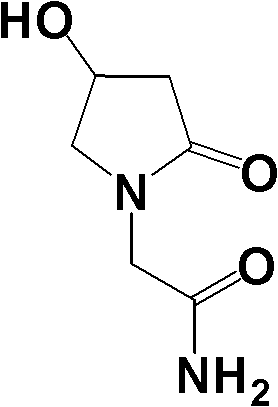

Method for refining oxiracetam

A refining method and crude product technology, applied in the direction of organic chemistry, can solve the problems of many by-products and low product quality, and achieve the effects of low cost, simple operation, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

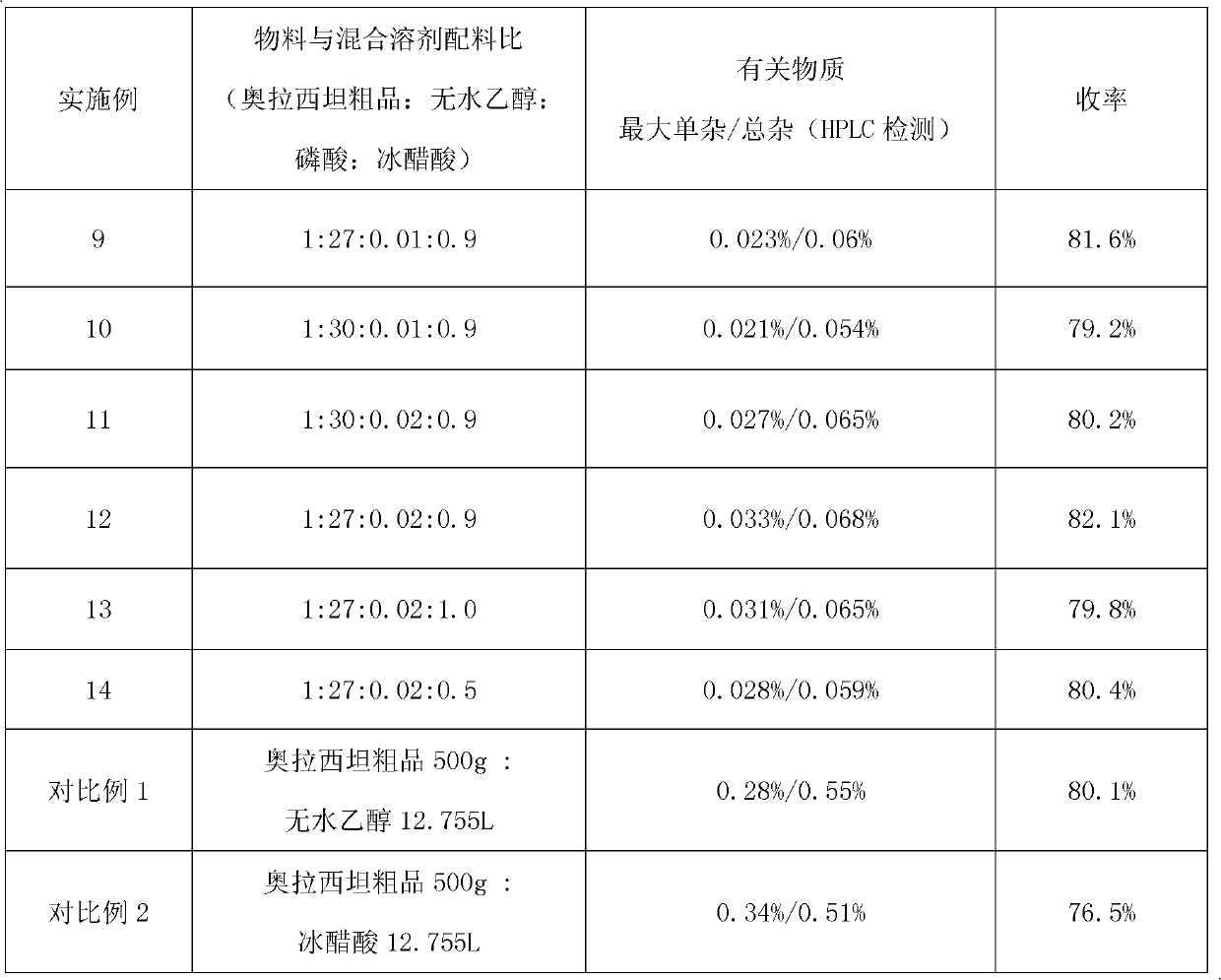

Examples

Embodiment 1

[0032] Embodiment 1, batching ratio: oxiracetam crude product: absolute ethanol: phosphoric acid: glacial acetic acid=1: 25: 0.01: 0.5.

[0033] The refining method of oxiracetam comprises steps as follows:

[0034] 1. Add 12.5L of absolute ethanol, 5ml of phosphoric acid, and 250ml of glacial acetic acid into a 20L three-necked flask in sequence, start stirring, and heat the water bath to 60°C±2°C.

[0035] 2. Add 500g of ground crude oxiracetam into the above reaction flask, stir and raise the temperature to 80°C±2°C for reflux, keep reflux at this temperature for 30min to fully dissolve it, then add 5g of activated carbon, stir, and keep reflux Temperature, continue to reflux for 20min.

[0036] 3. Turn off the heating of the water bath, filter the reaction solution while it is hot to obtain a colorless and clear solution, pour the solution into another clean 20L reaction bottle, stir, and circulate the ice and salt water to naturally cool the solution in the reaction bott...

Embodiment 2

[0039] Embodiment 2, ingredient ratio: oxiracetam crude product: absolute ethanol: phosphoric acid: glacial acetic acid=1: 27: 0.02: 0.7.

[0040] The refining method of oxiracetam, as described in embodiment 1, the difference is:

[0041] Add 13.5L of absolute ethanol, 10ml of phosphoric acid, and 350ml of glacial acetic acid into a 20L three-necked flask in sequence, start stirring, and heat the water bath to 60°C±2°C. The rest of the steps, dosage and conditions were the same as in Example 1 to obtain 402 g of oxiracetam fine product; the purity was 99.929%, the maximum single impurity was 0.033%, the total impurity was 0.071%, and the yield was 80.4%.

Embodiment 3

[0042] Embodiment 3, ingredient ratio: oxiracetam crude product: absolute ethanol: phosphoric acid: glacial acetic acid=1: 30: 0.05: 0.9.

[0043] 1. Add 15.0L of absolute ethanol, 25ml of phosphoric acid, and 450ml of glacial acetic acid into a 20L three-necked flask in sequence, start stirring, and heat the water bath to 60°C±2°C.

[0044] 2. Add 500g of ground crude oxiracetam to the above reaction flask, stir and heat up to 80°C±2°C for reflux, keep reflux at this temperature for 28min to fully dissolve it, then add 5g of activated carbon, stir and keep the temperature , continue to reflux for 20min.

[0045] 3. Turn off the heating of the water bath, and filter the reaction solution while it is hot to obtain a colorless and clear solution. Pour the solution into another clean 20L reaction bottle, stir, and circulate the ice-salt water to cool it down to 5-10°C naturally. Crystal 11h, crystallization is sufficient.

[0046] 4. Put the material into the centrifuge for centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com