Rotary vacuum device

A rotary, vacuum technology, applied in the field of mechanical structure, which can solve problems such as falling off, item displacement, and inability to fix lightweight items.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

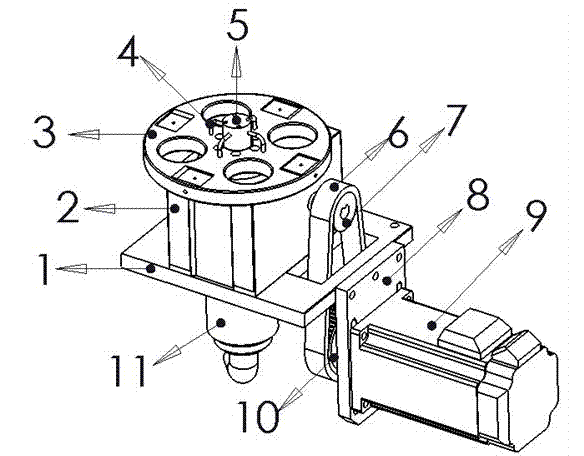

[0017] see figure 1 As shown, a rotary vacuum suction device includes a gap divider fixing plate 1 and a transmission motor plate 8, one side of the gap divider fixing plate 1 and the transmission motor plate 8 are fixed by screws, and the gap divider Gap divider 2 is fixed on the upper part of the device fixing plate 1, and a single-channel rotary joint 11 is fixed on the lower part. The pipeline type turntable 3 is directly locked on the flange of the gap divider 2, and the vacuum flange head 5 is fixed on the vacuum pipe 4. On the pipe-type turntable 3; the transmission motor plate 8 is provided with a transmission motor 9, the transmission motor 9 passes through the transmission motor plate 8 and is provided with a driving wheel 10, and the gap divider 2 is provided with a driven wheel 7. The driving wheel 10 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com