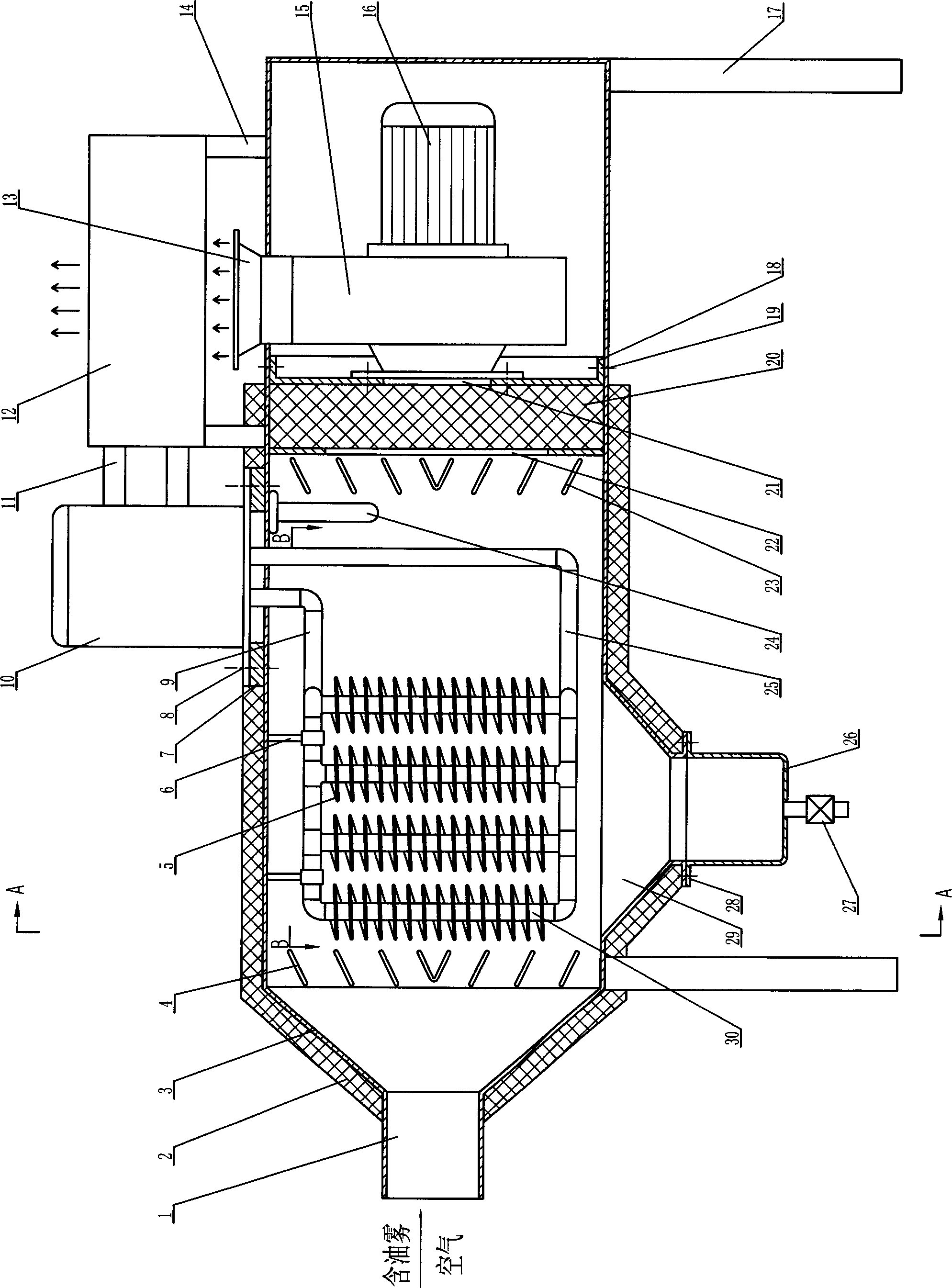

Condensing oil mist purifier

A purification machine and condensing technology, which is applied in the direction of steam condensation, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of burning motors, large resistance, and low efficiency of oil mist molecular clusters, and achieve the effect of improving the purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

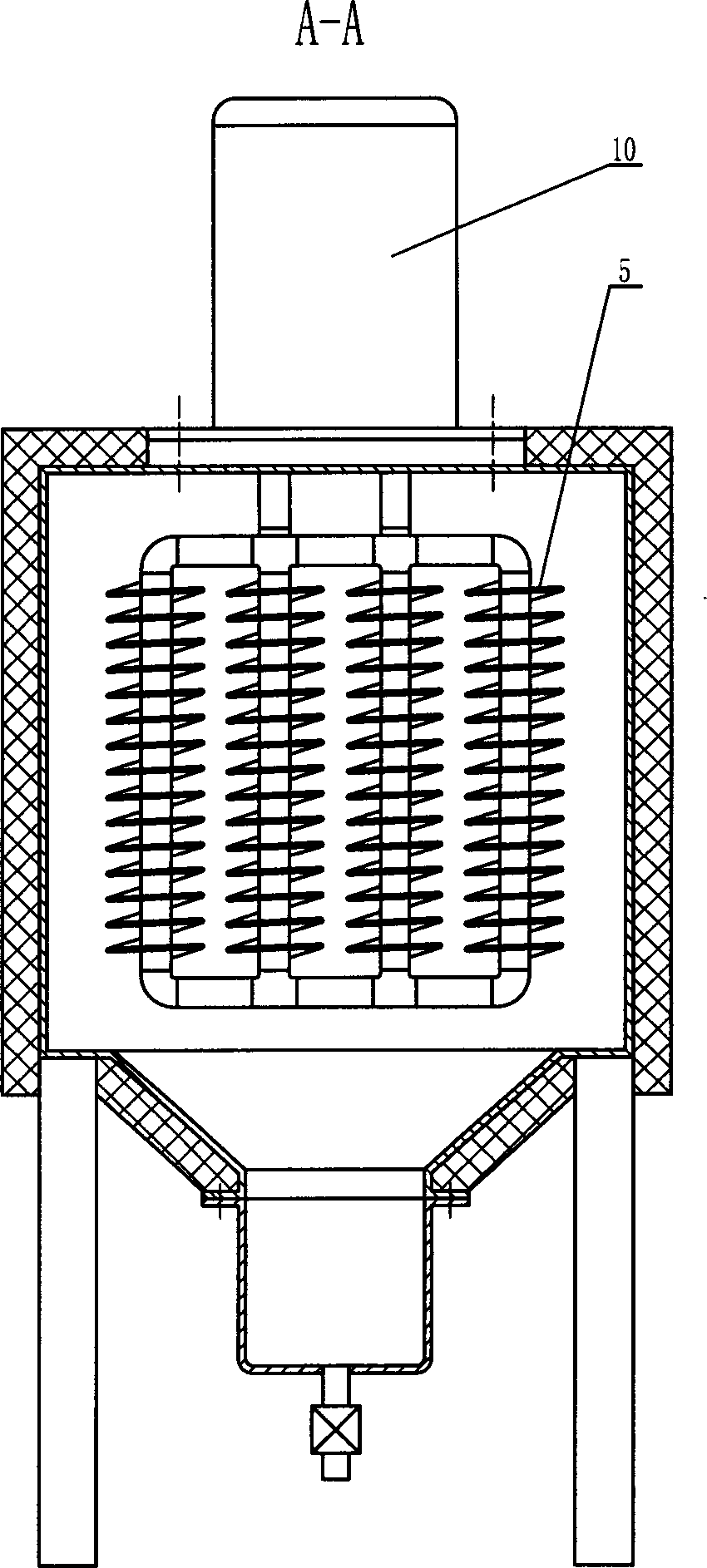

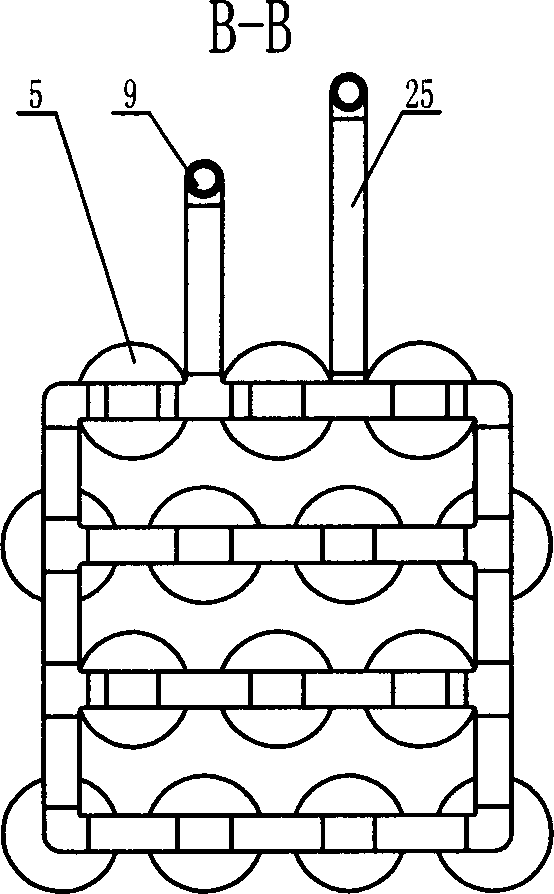

[0020] The oil mist inlet (1) is installed at the front end of the sealed casing (3), and a group of front air equalizing plates (4) are evenly fixed in the sealed casing (3) behind the oil mist inlet (1), and the heat exchange fins (5 ) are wound on the heat exchange tube (30), and communicate with the cooling medium outlet pipe (9) and the cooling medium inlet pipe (25) respectively, and the cooling medium outlet pipe (9) is fixed on the sealing Inside the casing (3). The cooling medium outlet pipe (9) and the cooling medium inlet pipe (25) are respectively communicated with the refrigeration compressor (10), and the refrigeration compressor (10) is fixed on the sealed casing (3) by the backing ring (7) and the compressor bolt (8). )above. The refrigeration compressor (10) communicates with the radiator (12) through the heat dissipation pipe (11), and the radiator (12) is fixed on the sealed casing (3) through the radiator legs (14). A temperature sensor (24) is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com