Inner barrel of particle washing machine

A washing machine and inner drum technology, applied in the field of washing machines, can solve the problems of not being suitable for the working mode of granular washing machines, and achieve the effects of simple structure, enhanced ability to resist centrifugal force deformation, and increased turning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

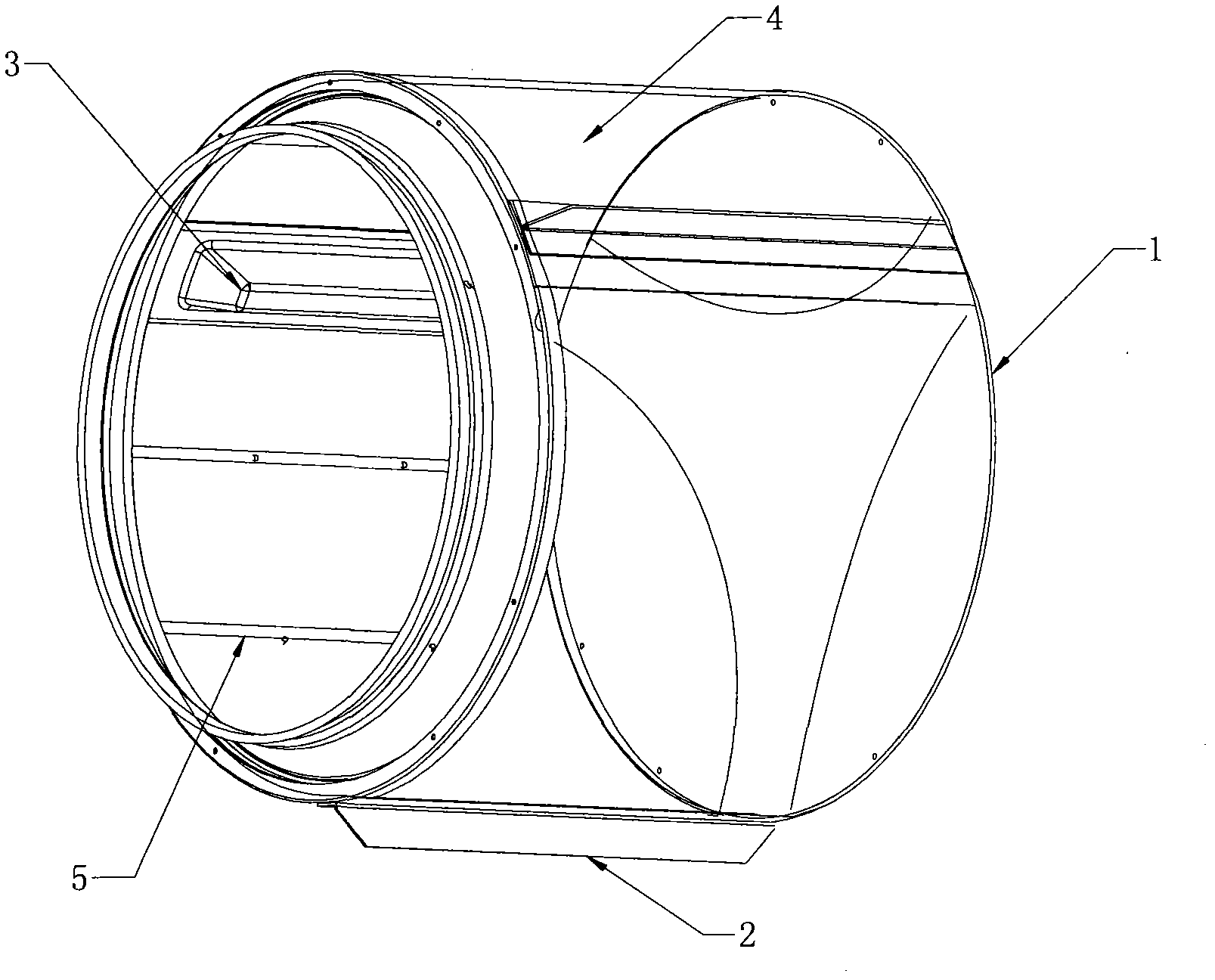

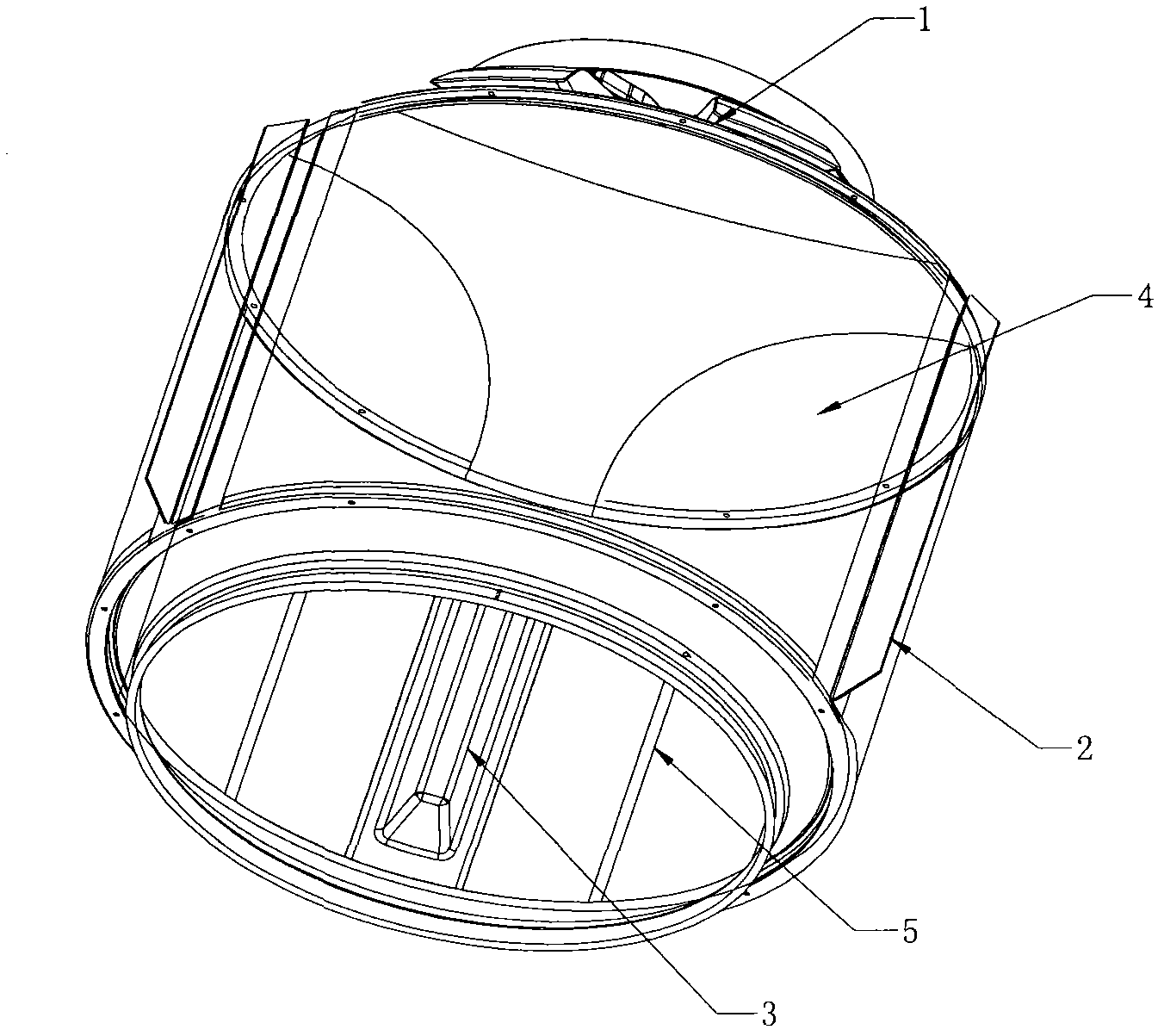

[0033] Such as figure 1 , 2 , 3, in the present invention, the cylinder wall 4 of the inner cylinder 1 is all made of metal grids, the diameter of the grid is larger than the diameter of the particles used for washing, and three scrapers 2 are evenly arranged on the outer axial direction of the cylinder wall , the scraper 2 adopts an L-shaped metal structure, one side is fixed on the cylinder wall, the length of the scraper is consistent with the length of the cylinder wall, the height of the scraper is smaller than the gap between the inner cylinder and the outer cylinder, and the optimal distance between the scraper and the outer cylinder is The minimum distance is 1 to 1.5 cm, which can prevent the inner cylinder from colliding with the outer cylinder when rotating.

[0034] When this scheme is working, the particle storage box located on the outer cylinder puts the particles in from the upper part of the outer cylinder, and the particles enter the inner cylinder through t...

Embodiment 2

[0037] Such as figure 1 , 2 As shown, in order to strengthen the strength of the inner cylinder 1 and counteract the centrifugal force during rotation, this solution is based on the above-mentioned embodiments, and reinforcing ribs 5 are arranged at intervals on the wall of the inner cylinder, and the reinforcing ribs are made of cylindrical metal or plastic. The ends are respectively fixed at the bottom and top of the inner cylinder.

[0038] This scheme strengthens the structure of the inner cylinder, reduces the load on the wall of the inner cylinder, and reduces the shaking range when the inner cylinder rotates.

Embodiment 3

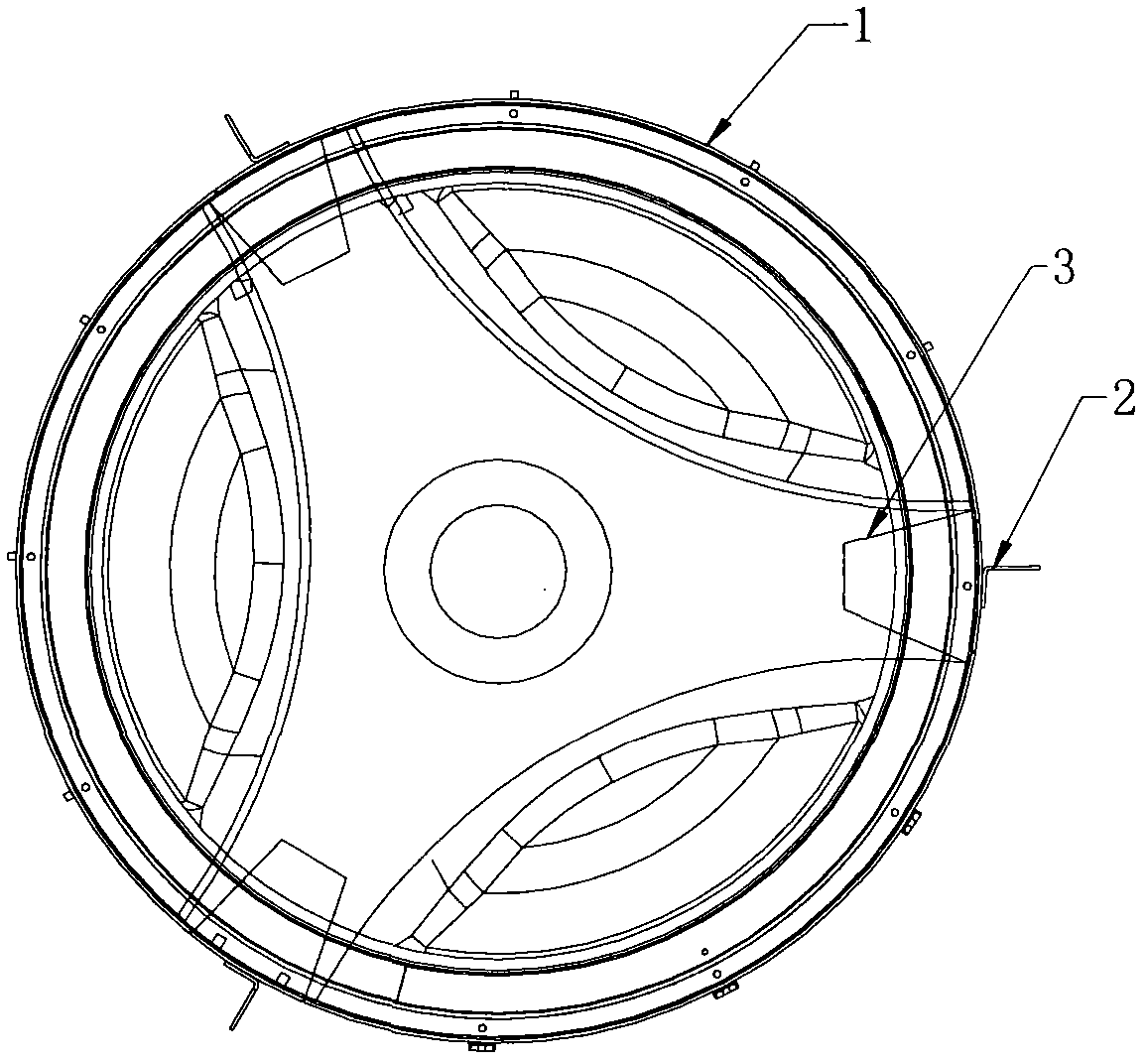

[0040] Such as figure 1 , 4 As shown in , 5, in order to improve the agitation range of the clothes and particles in the inner cylinder 1, a water-repellent sheet 3 is set in the inner cylinder in this scheme, and the water-repellent sheet adopts a split-type adjustable structure, and the water-repellent sheet includes a base 31 and a movable block 32, Wherein the base is fixed on the inner side of the inner cylinder wall, the base is provided with a long groove, the movable block is inserted in the long groove, two rows of screw holes 34 are opened on one side of the movable block, and a fixed screw hole is opened on the position of the base relative to the screw holes. Hole 33, when movable block inserts base, after adjusting suitable height, the screw hole 34 of place height is aligned with the fixed hole 33 on the base, utilizes screw to be fixed by fixed hole movable block.

[0041] The height of the water-repellent sheet in this solution is higher than the ribs in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com