Optical product and plastic lens for eyeglass

A technology for optical products and plastic lenses, applied in glasses/goggles, optics, nano-optics, etc., can solve problems such as ease of operation, and achieve the effects of maintaining durability, not affecting transparency, and excellent antistatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

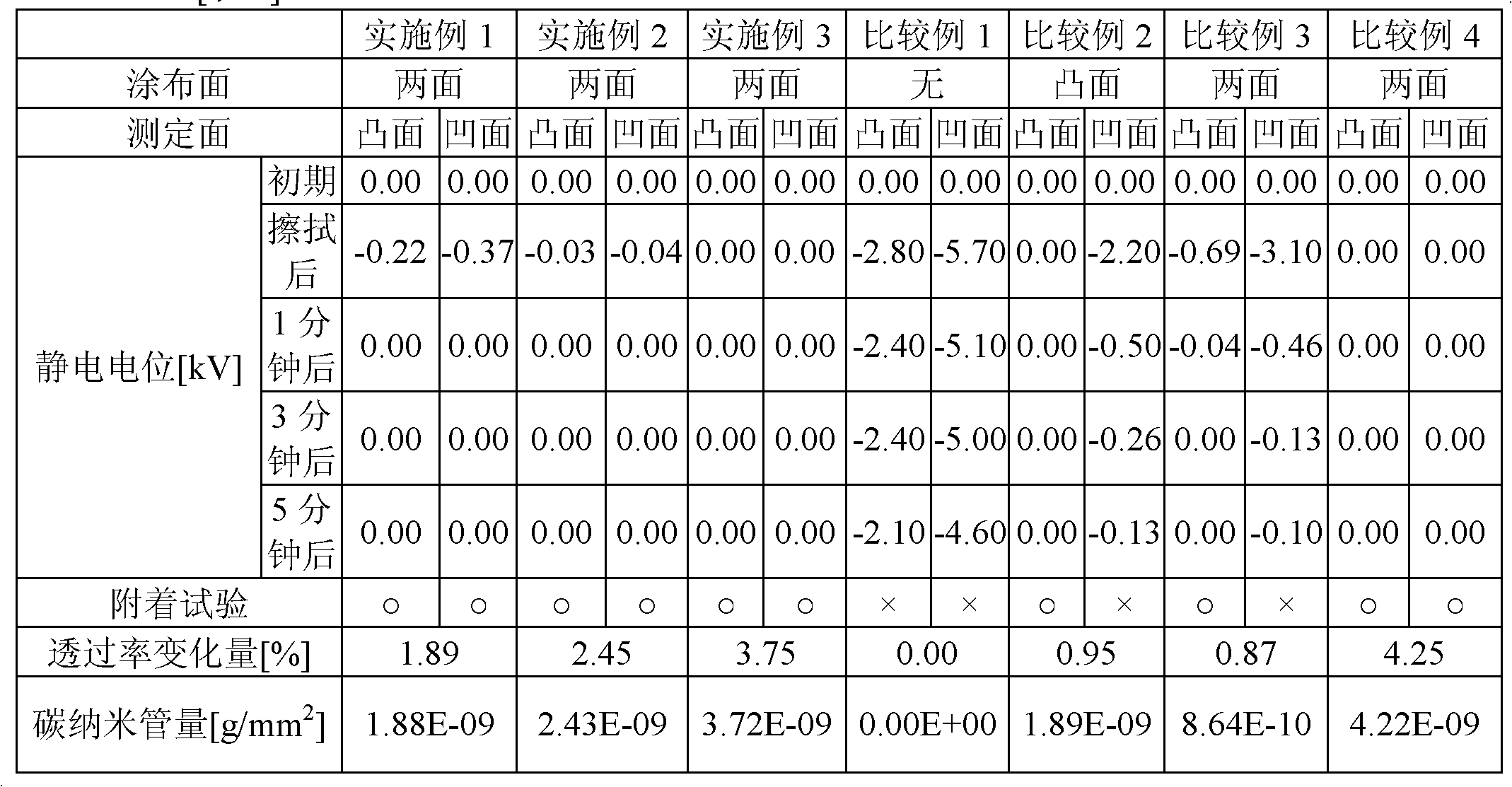

[0033] Next, Examples and Comparative Examples of the present invention are given. However, these examples do not limit the scope of the present invention.

[0034] (transmittance change amount and carbon nanotube amount per unit area)

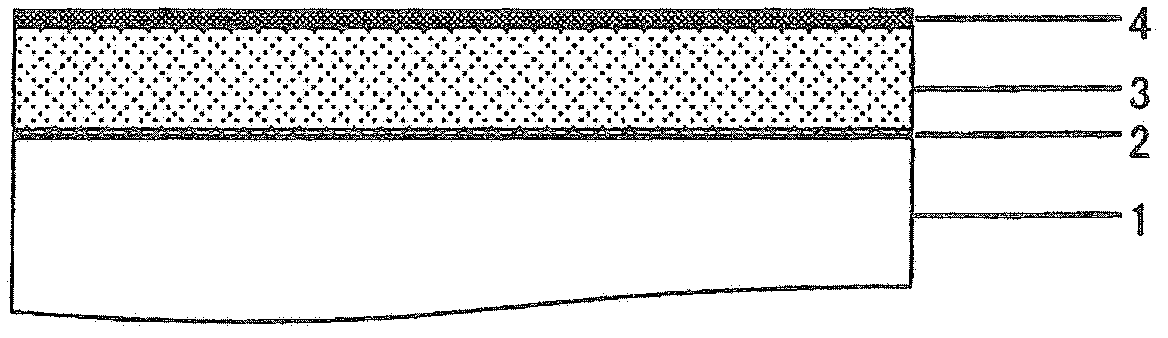

[0035] The carbon nanotube dispersion liquid is uniformly applied to one surface of the lens substrate 1 so that the dispersion liquid does not scatter, and dried to form the carbon nanotube accumulation layer 2, and the transmittance of the obtained object is obtained. The amount of change and the amount of carbon nanotubes per unit area to get their correlation. For example, on the lens substrate 1 of a spectacle lens with a diameter of 75mm, 0.25ml (milliliters) of 0.0128wt% (percentage by weight) carbon nanotube ethanol dispersion is dropped, and when coating is carried out as above, the amount of change in transmittance 0.7%, the amount of carbon nanotubes per unit area is 1.39E-9g / mm 2 . It should be noted that the lens (optical prod...

Embodiment 2

[0041] In Example 2, the evaluation was performed on the performance change after being left for 7 days in an environment of 60 degrees Celsius (the same applies hereinafter) and 95% of the temperature.

[0042] (Formation of carbon nanotube stacked layer)

[0043] The carbon nanotube stacked layer 2 was formed using a spin coater. A carbon nanotube ethanol dispersion (manufactured by MeijoNanoCarbon Co., Ltd., 0.0128 wt%) was dropped onto the spectacle lens, rotated at a rotation speed of 1000 rpm for 30 seconds, and dried at 60 degrees for 15 minutes to remove the solvent, thereby forming Carbon nanotube accumulation layers 2 are formed on both surfaces of 1. In addition, the spectacle lens has the optical characteristics of a refractive index of 1.6, an Abbe number of 42, and a diopter of -2.00.

[0044] (formation of dura layer)

[0045] 206 g of ethanol, 300 g of methanol-dispersed titanium dioxide-based gel (manufactured by Nikki Catalyst Chemicals Co., Ltd., solid co...

Embodiment 1

[0049] The carbon nanotube accumulation layer, the hard coat layer, and the antireflection film are formed on both surfaces of the lens substrate 1 . In addition, the dropwise amount of the carbon nanotube dispersion liquid on each surface was set to 1.00 ml.

[0050] (Example 2)

[0051] In Example 1, the dropwise amount of the carbon nanotube dispersion liquid on each surface was set to 1.50 ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com