Elasticity detection device for plate spring and method for detecting plate spring by using same

A technology of detection device and force application device, which is applied in the direction of measuring device, measurement of elastic deformation force through measuring gauge, elastic test, etc., and can solve problems affecting the normal detection of other elastic parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

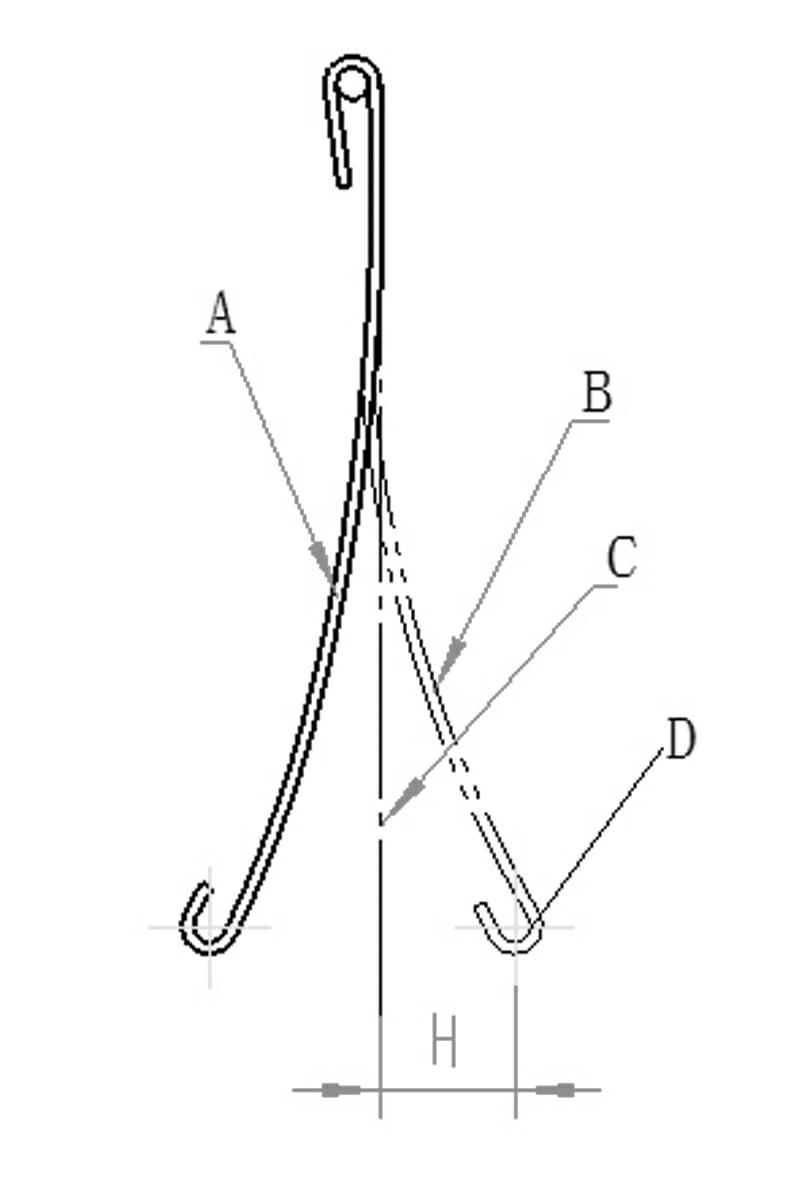

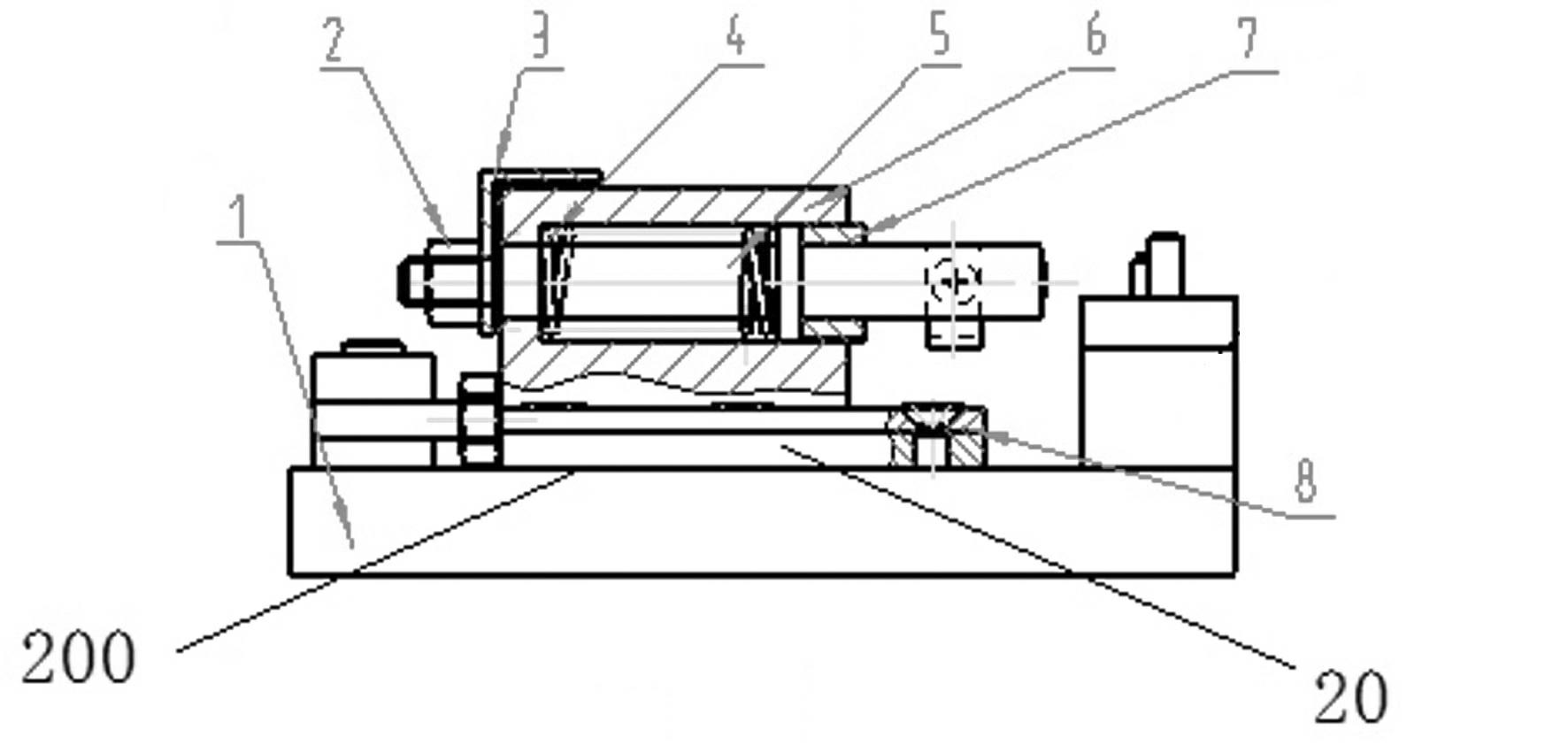

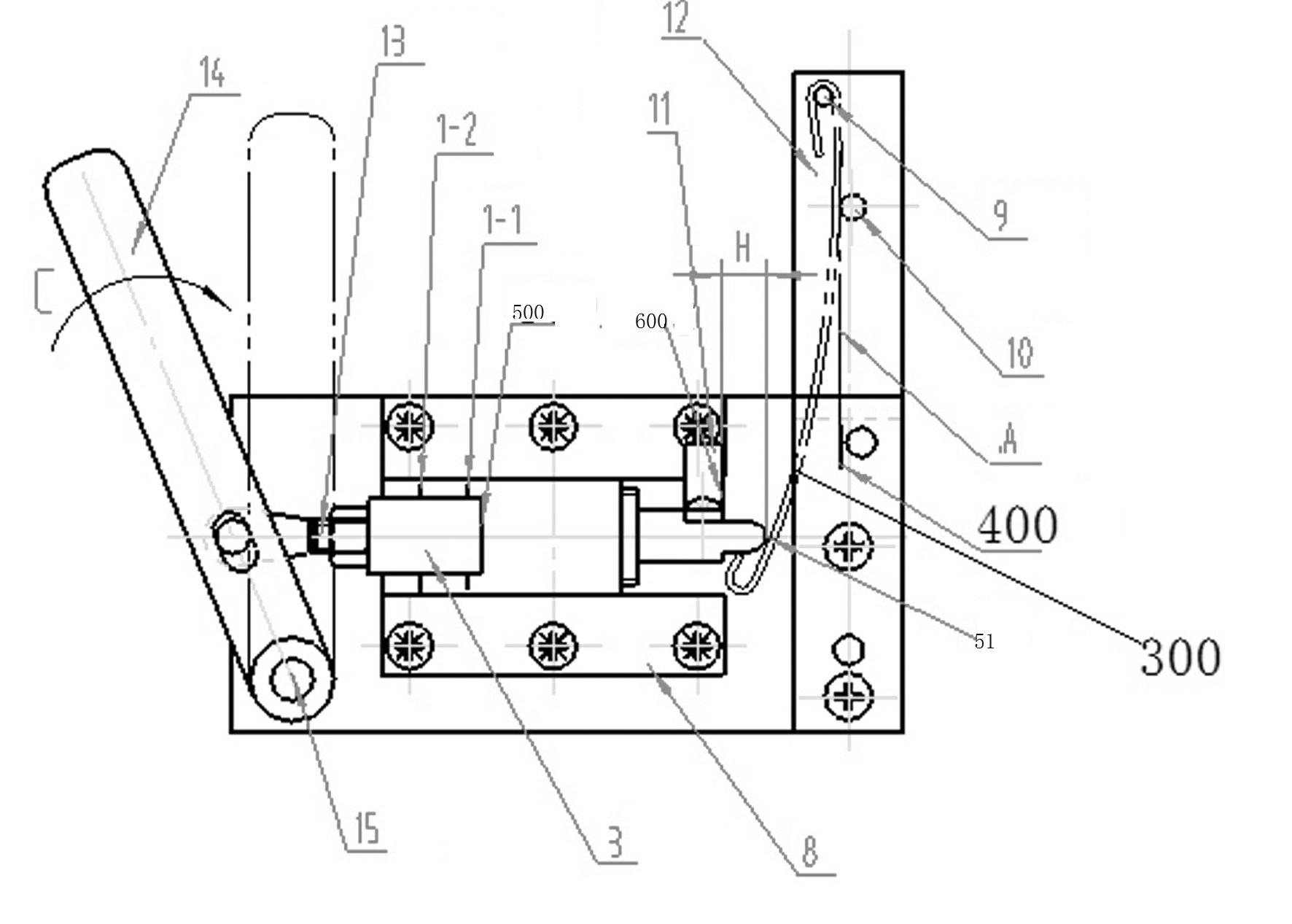

[0026] like Figure 2 to Figure 7Shown, a kind of embodiment of leaf spring spring force detection device, the detection device provided in this embodiment comprises the leaf spring seat 12 that is used to fix one end of leaf spring 300 and makes the other end of leaf spring free end and is used for test plate The force applying device 200 of spring force, the force applying device 200 comprises a base 1, a guide mechanism is arranged on the base 1, and a push rod seat 6 is installed on the guide mechanism along the front and rear direction, and the leaf spring seat 12 is located on the force applying device. 200 ahead, the leaf spring seat 12 extends along the guiding direction perpendicular to the front-to-back direction and is fixed on the base 1. The leaf spring seat 12 is provided with a positioning pin 9 for fixing one end of the leaf spring. There is a stop pin 10 for marking the reference line of the leaf spring on the leaf spring seat to prevent excessive elastic defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com