Automatic sheet packing device for lead-acid battery production

A lead-acid battery, automatic technology, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of serious lead pollution, unfavorable workers' health, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

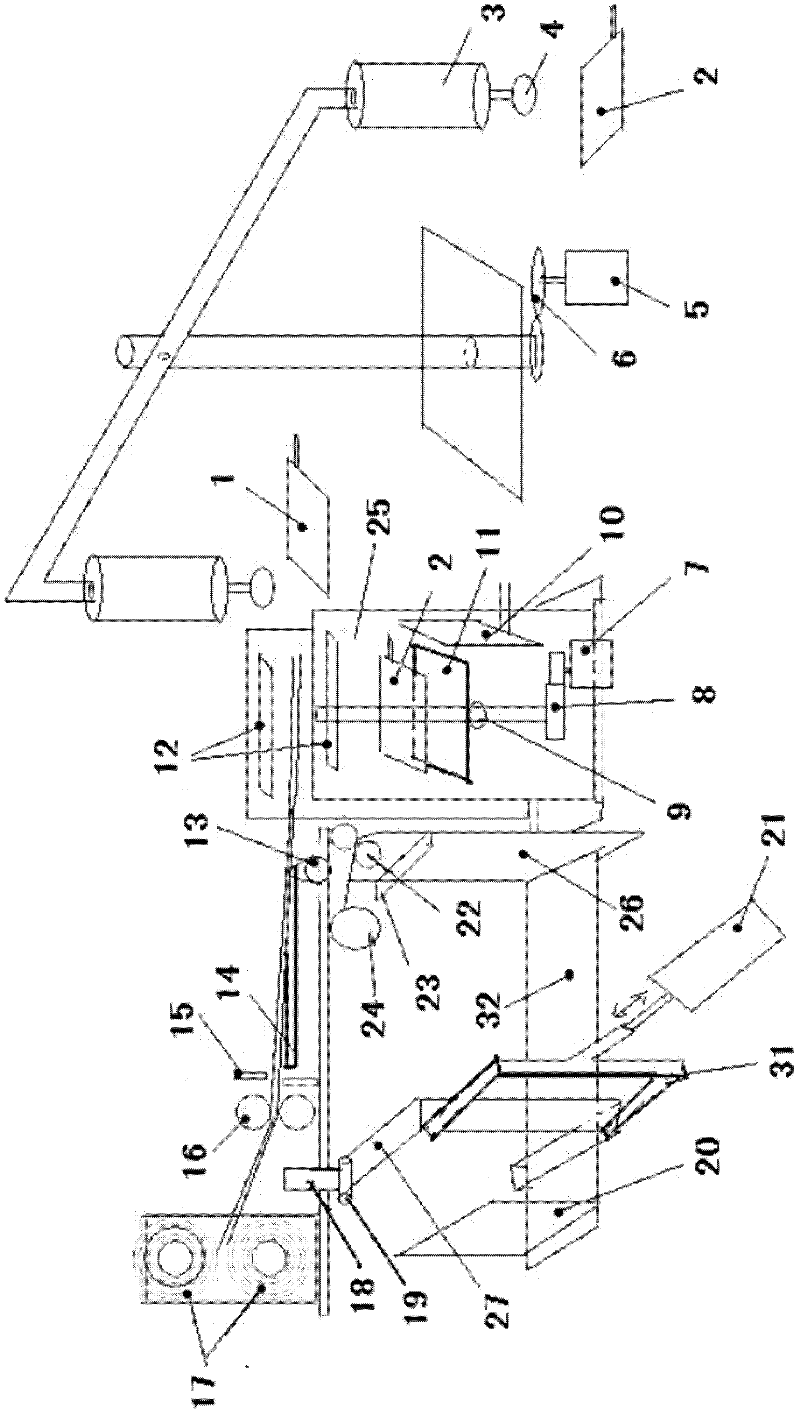

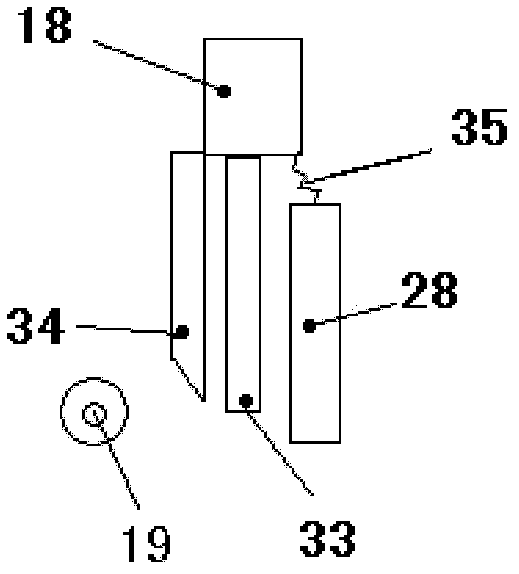

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] like Figure 1-3 , the automatic wrapping device for the production of lead-acid batteries in this embodiment includes: using an automatic sheet feeding device to remove a preset number of positive and negative sheets from the positive sheet stack and the negative sheet stack respectively and alternately stack them one by one on a tray and form a stack of rectangular cylinders; during the process of alternately stacking the positive and negative films one by one on the support, a paper feeding mechanism is used to insert cellophane for isolation between the positive and negative films; After the preset number of positive and negative films are stacked, a packing mechanism uses plastic paper to pack the stack, and finally a wrapping mechanism wraps the stack with plastic tape.

[0016] The film support is horizontally arranged on a vertical lifting mechanism, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com