Calibration device of triaxial acceleration sensor and calibration method thereof

A technology of acceleration sensor and calibration device, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measurement devices, etc., which can solve problems such as the inability to guarantee measurement accuracy, and meet calibration requirements, The effect of simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In conjunction with accompanying drawing and specific embodiment, the present invention is described further:

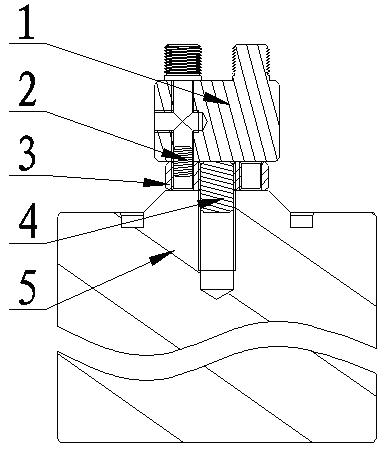

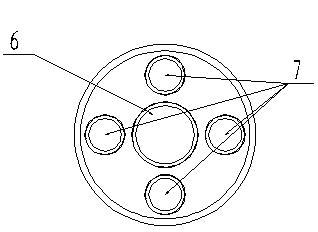

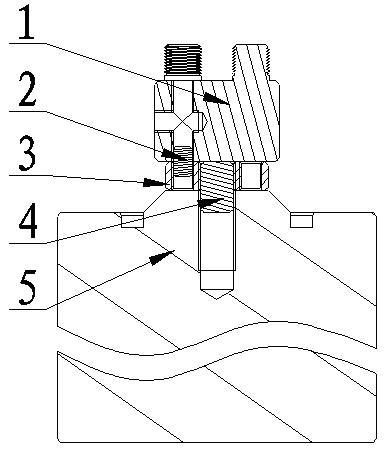

[0013] like figure 1 As shown, a calibration device for a three-axis acceleration sensor, the calibration device includes a standard vibration source 5 and an adapter base 3; the standard vibration source 5 is a uniaxial acceleration correction source commonly used in the prior art ; The adapter base 3 arranged under the triaxial acceleration sensor 1 is disc-shaped; there is a threaded hole I6 at the center of the adapter base 3, and there is a screw hole with the same diameter as the threaded hole I6 at the center of the standard vibration source The threaded hole is passed through the threaded hole I6 by the stud I4, and the threaded hole on the standard vibration source is used to fix the transfer base 2 on the standard vibration source 5; along the threaded hole I6 on the end surface of the transfer base 3 A plurality of threaded holes II7 for connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com