Electric louver structure

A louver structure and electric technology, which is applied to windows/doors, building components, building structures, etc., can solve the problems that users cannot temporarily control the opening and closing of louvers manually, high price, and high energy consumption, so as to achieve anti-theft and ventilation Low performance, low cost and energy consumption, and the effect of improving the structure of doors and windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

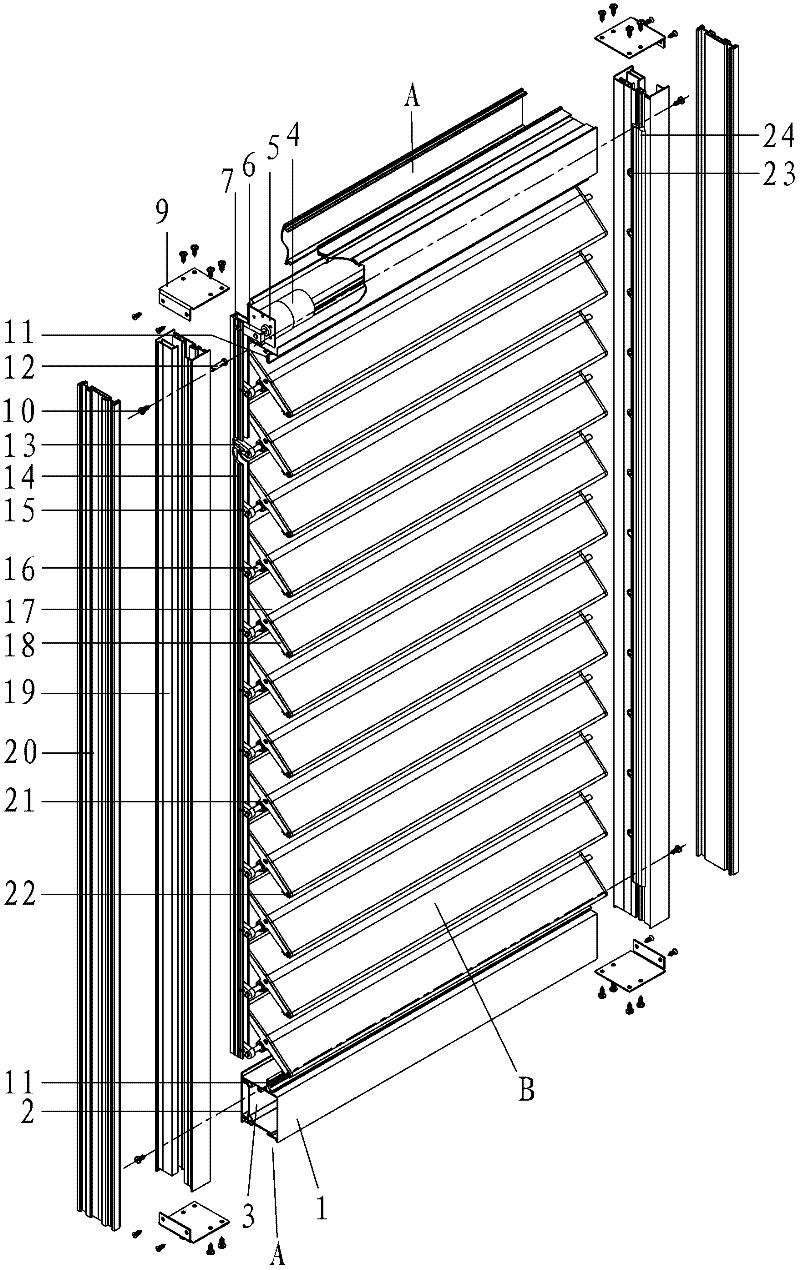

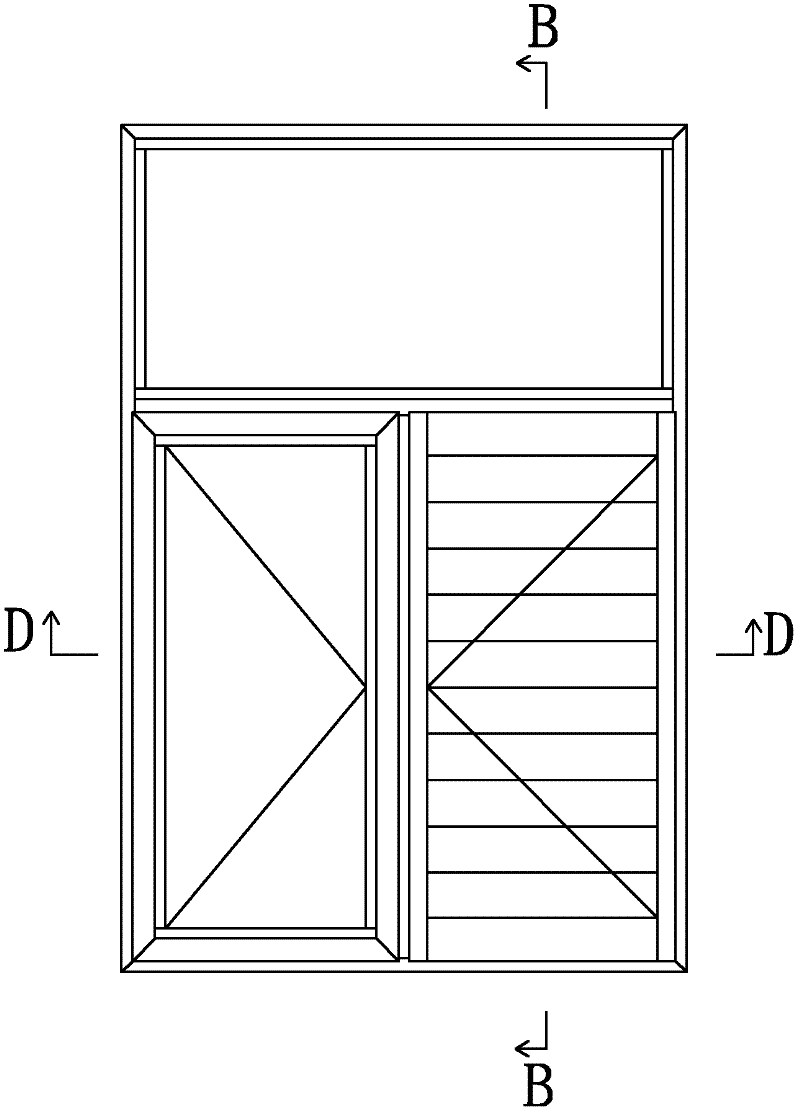

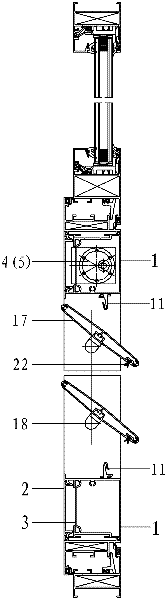

[0022] like Figures 1 to 4 As shown, the electric shutter structure of the present invention includes a window frame, a plurality of shutter assemblies B and a drive assembly that drives the shutter assemblies to swing, wherein the window frame includes two mullion assemblies arranged on both sides and two The lower horizontal frame assembly A, the two mullion assemblies are respectively used as the left and right mullion assemblies, the two horizontal frame assemblies are respectively used as the upper and lower horizontal frame assemblies, and the two ends of each louver assembly B are connected with the left and right mullion assemblies respectively. Relatively rotatable mating connection. The drive assembly includes a motor 4, a drive guide rod 14, a motor swing arm 6, a motor swing arm pin 7, a blade swing arm 13 and a blade swing arm pin 15 corresponding to the louver assembly B one by one, and the motor 4 can pass through the motor bracket 5 Installed in the upper hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com