High-fat flavoring wine containing healthy flavor components and preparation method thereof

A technology of flavor components and seasoning wine, which is applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of excessive alcohol body hygiene indicators such as fusel oil, and achieve a more typical style of wine body. The effect of elegant and delicate wine body and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

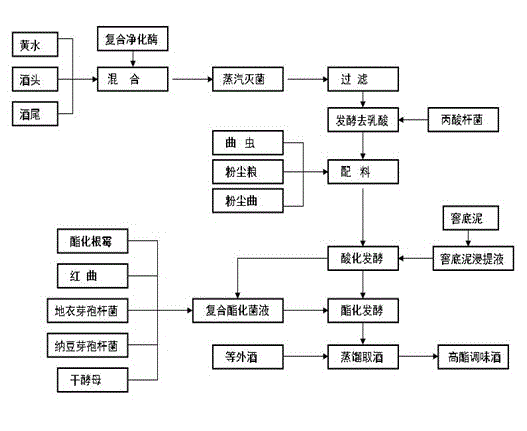

Method used

Image

Examples

Embodiment 1

[0066] 1. Raw and auxiliary materials

[0067] ① Yellow water: solid-state Luzhou-flavor liquor brewed and fermented normally without peculiar smell, fresh liquid, acidity 5.3, total ester 1.01g / 100ml;

[0068] ② Head and tail: the mixture of liquor and water distilled first and last during the distillation of solid Luzhou-flavor liquor, of which the alcohol content of the head is 67% vol, and the tail is 15% vol.

[0069] ③ Aspergillus: Aspergillus powder after crushing dried Aspergillus produced in the process of medium-to-high temperature Daqu production environment.

[0070] ④ Dust grain: the fine powder mixture produced during the crushing process of rice, wheat, sorghum, corn, and glutinous rice.

[0071] ⑤Dust koji: During the production process of Maotai-flavored Daqu medicine, due to handling and other activities, the koji pieces are not formed, and the fine powder produced by the koji medicine during the crushing process can pass through the 1mm sieve.

[0072] ...

Embodiment 2

[0107] 1. Raw and auxiliary materials

[0108] ①Yellow water: fresh liquor with no peculiar smell, acidity 5.0, total ester 0.56g / 100ml;

[0109] ② Liquor head and tail: the first and last distilled wine and water mixture in the distillation process of solid Maotai-flavored liquor, the alcohol content of the head is 68% vol, and the alcohol content of the tail is 19% vol.

[0110] ③ Aspergillus: Aspergillus powder after crushing dried Aspergillus produced in the high-temperature Daqu production environment.

[0111] ④ Dust grain: the fine powder mixture produced during the crushing process of rice, wheat, sorghum, corn, and glutinous rice.

[0112] ⑤Dust koji: During the production process of Maotai-flavored Daqu medicine, due to handling and other activities, the koji pieces are not formed, and the fine powder produced by the koji medicine during the crushing process can pass through the 1mm sieve.

[0113] ⑥ Rhizopus esterification, Monascus, Bacillus licheniformis, Prop...

Embodiment 3

[0143] 1. Raw and auxiliary materials

[0144] ①Yellow water: Fresh liquor with no peculiar smell and normal fermentation of Fen-flavor liquor by solid-state method, with an acidity of 5.0 and a total ester of 0.26g / 100ml;

[0145] ②Liquor head and tail: the first and last distilled wine and water mixture in the distillation process of solid-flavored liquor, of which the alcohol content of the head is 70% vol. The alcohol content of the tail is 15% vol.

[0146] ③ Aspergillus: Aspergillus powder after crushing dry Aspergillus produced in the process of making Daqu at medium temperature.

[0147] ④ Dust grain: the fine powder mixture produced during the crushing process of rice, wheat, sorghum, corn, and glutinous rice.

[0148] ⑤Dust koji: During the production process of Maotai-flavored Daqu medicine, due to handling and other activities, the koji pieces are not formed, and the fine powder produced by the koji medicine during the crushing process can pass through the 1mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com