Active film unwinding device

An unwinding device and active technology, applied in the field of machinery, can solve the problems of unwinding speed control, affecting the use effect, film stretching, etc., and achieve the effect of improving the quality of warp knitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

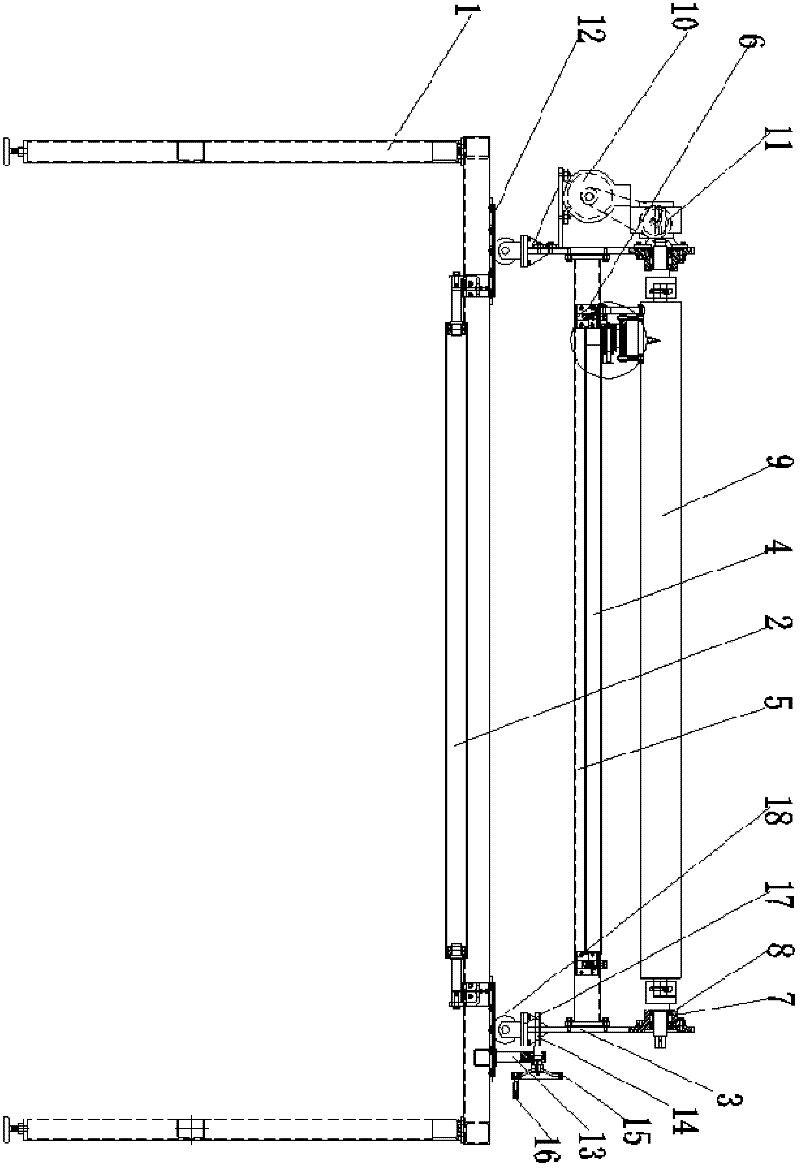

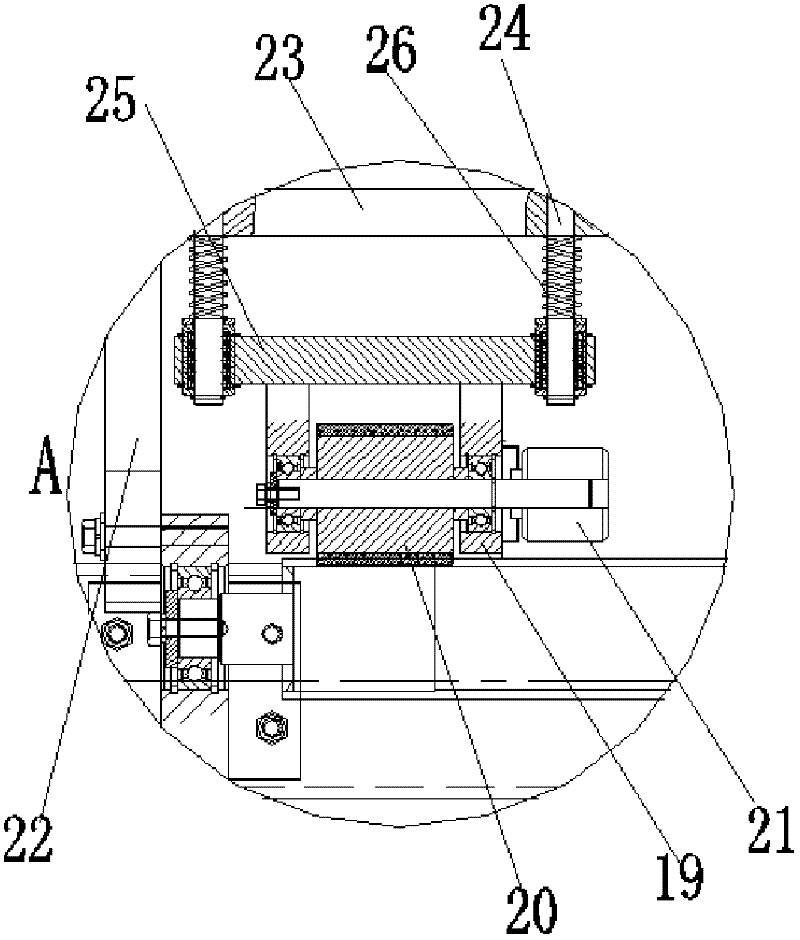

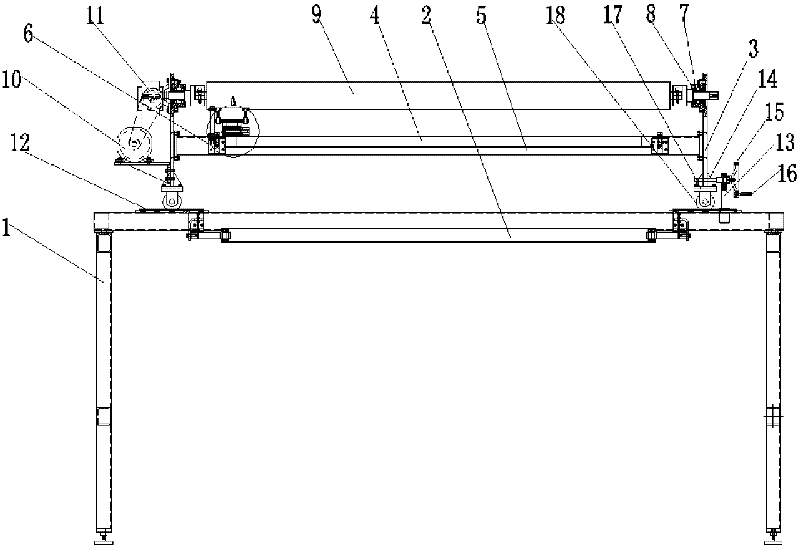

[0012] refer to figure 1 A kind of active film unwinding device shown, it comprises support 1, the unwinding mechanism that is arranged on support 1 and guide roller 2, and described unwinding mechanism comprises fixed frame 3, is arranged on fixed frame 3 and unwinds The roll assembly, the transition roller 4 and the unwinding tension pipe 5 are provided with a transition roller installation frame 6 for assembling the transition roller 4 on the fixed frame 3, and a speed measurement feedback mechanism is also provided on the transition roller installation frame 6. The unwinding assembly includes a bearing seat 7 arranged on the fixed frame 3, a bearing 8 inside the bearing seat 7, an air shaft 9 supported by the bearings 8 at both ends, a servo motor 10 and a synchronous pulley for driving the air shaft 9 to rotate 11. The speed measurement feedback mechanism is connected with the servo motor 10 .

[0013] On the basis of the foregoing solution, further, the support 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com