Method for laser powder-filled welding of aluminum/steel dissimilar metal joint without brazing flux

A dissimilar metal, flux-free technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of flux usage restrictions, environmental pollution, etc., to improve joint quality, increase utilization rate, and increase absorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: the connection of 6061 aluminum alloy and galvanized steel plate

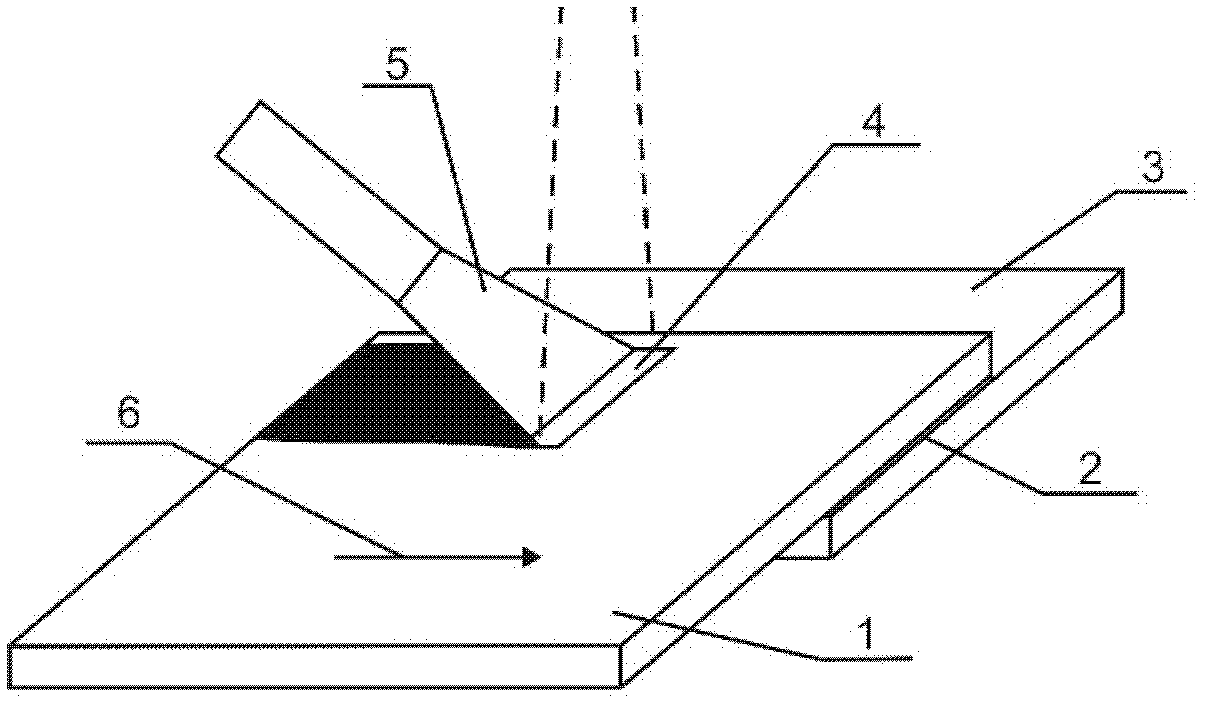

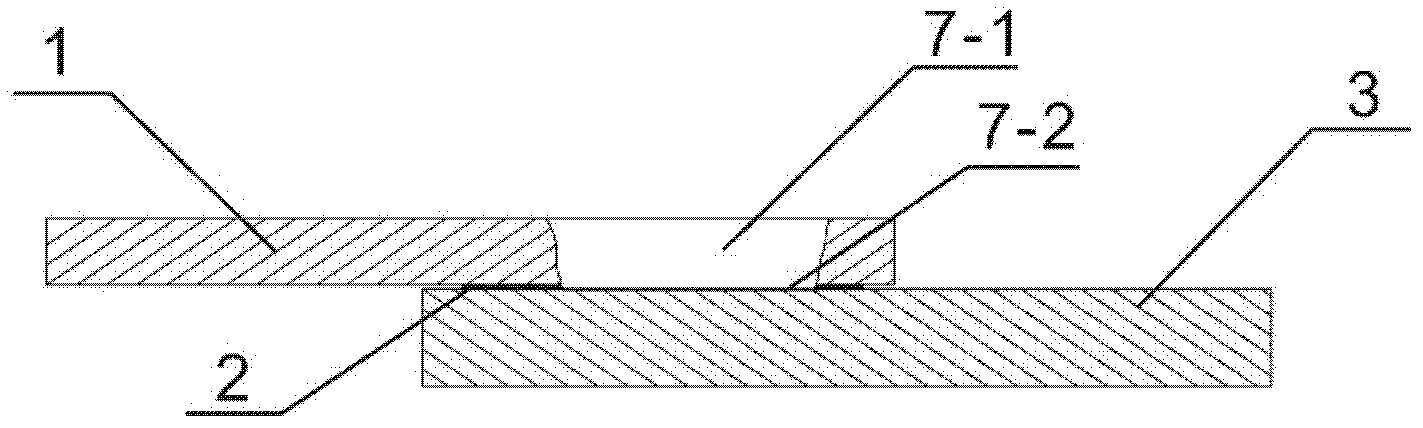

[0026] The laser used in the experiment is an ytterbium-doped fiber laser produced by IPG Photonics, the model is YSL-6000, the rated power is 6.0kW, and the output wavelength is 1.06μm. The Gaussian spot is shaped into a rectangular uniform spot. The filling powder is AlSi12 powder produced by Sulzer Metco. The filling brazing filler metal is AlSi12 eutectic alloy brazing filler metal with a thickness of 0.15 mm. To match the laser beam, a wide-band powder feeding nozzle is selected, and the outlet size of the powder beam is 4×0.5mm.

[0027] The welding specifications are as follows:

[0028] The welding speed is 0.6m / min, the laser power is 6000W, and the spot size of the laser beam on the workpiece surface is 3.7×7.3mm. The powder feeding rate is 2.5g / min, the protective gas is argon, and the flow rate is 5L / min.

[0029] The workpiece size is:

[0030] 6061 aluminum alloy: 50mm×100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com