Special sling device used for lifting nuclear waste

A technology for nuclear waste and spreader, which is used in transportation and packaging, load hoisting elements, and load-carrying pulleys, etc., can solve the problems of inability to meet the requirements of lifting and transporting nuclear waste, high hazards, etc., and achieves avoiding swing, accurate positioning, and improving safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

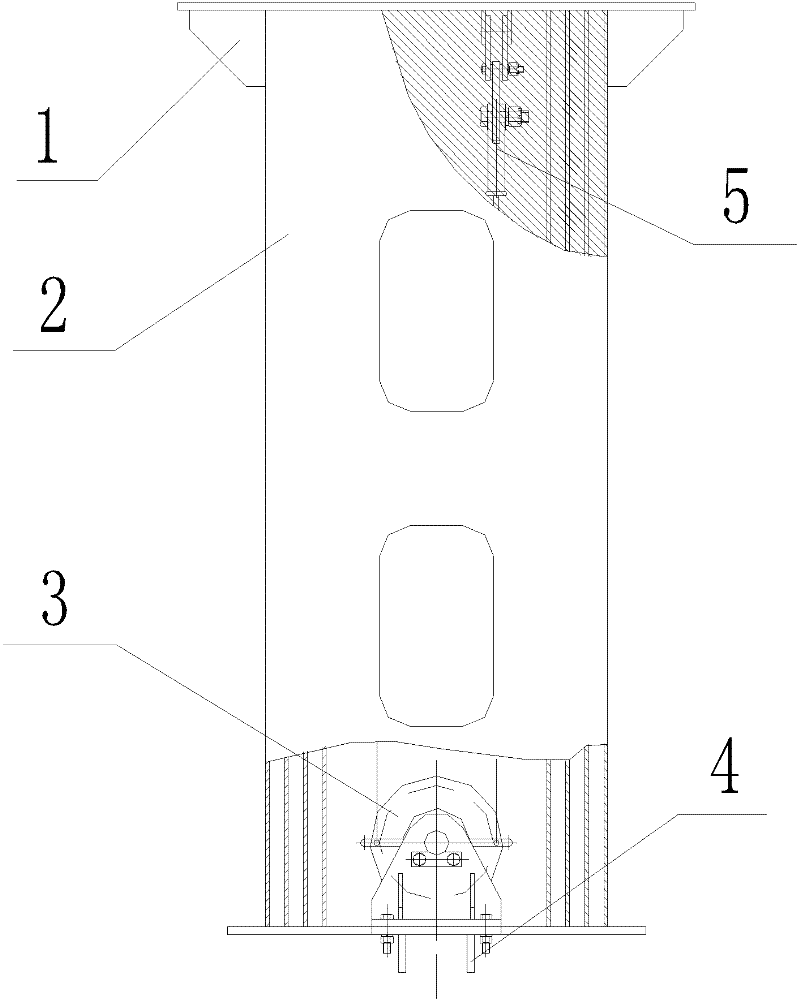

[0017] see Figure 1-Figure 4 , a special spreader device for lifting nuclear waste, including a connecting plate 1 installed on the beam of the trolley frame. The connecting plate is equipped with a telescopic sleeve device 2, and the telescopic sleeve device is composed of a multi-section sleeve 2-1 through a nested structure, that is, adjacent two-section sleeves are nested with each other, and can be Move sequentially in the same direction. A guide slider 2-2 for sliding up and down and a positioning block 2-3 for fixing are formed on each section of the sleeve 2-1. In this embodiment, four of each section of the sleeve 2-X All be provided with guide slide block 2-2 and positioning block 2-3 on the surface. Due to the different heights...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com