Chassis driving system of crane, chassis and crane

A drive system and crane technology, which is applied in the direction of cranes, construction cranes, traveling mechanisms, etc., can solve the problems of reducing the traveling power of the crane, affecting the traveling speed of the crane, and the crane being unable to move, so as to improve the driving force, reduce the lack of driving force, The effect of improving load traveling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

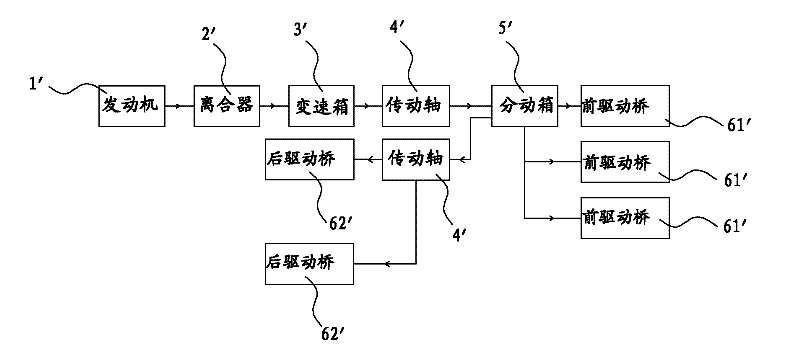

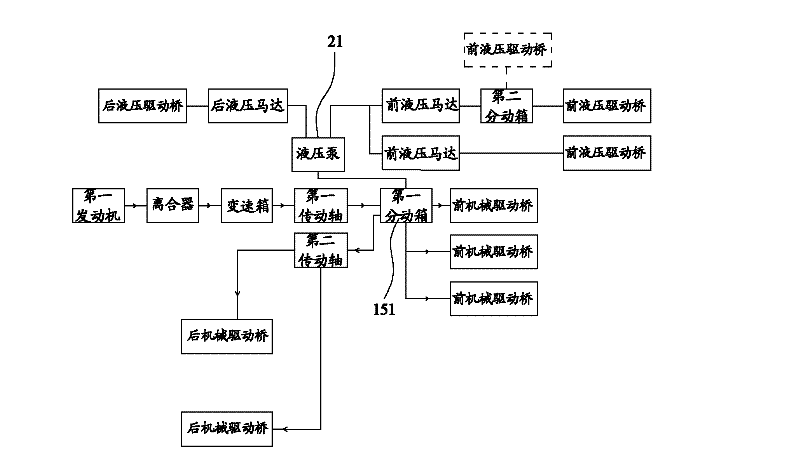

[0029] In order to solve the problem of insufficient driving force under the condition of heavy load of the crane, the embodiment of the present invention adds an independent hydraulic drive device to the drive system of the crane chassis, so that the crane can change from the original driving mode that only relies on the mechanical drive device to provide power. The dual power mode of the mechanical driving device and the hydraulic driving device can provide driving force to the crane simultaneously with the mechanical driving device on the one hand, improving the driving force of the crane. On the other hand, when the crane is driving on uneven roads, even if part of the mechanical drive axle slips, the hydraulic drive device can be used to provide driving force for the crane, thereby improving the off-road driving ability and off-road performance of the crane chassis.

[0030] Embodiments of the present invention will be described in detail below with reference to the accomp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com