Dust-gas mixing device for semi-dry desulphurization reactors

A semi-dry desulfurization and mixing device technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as the inability to humidify the mixed ash evenly distribution, the inability of flue gas purification to operate efficiently, and achieve efficient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

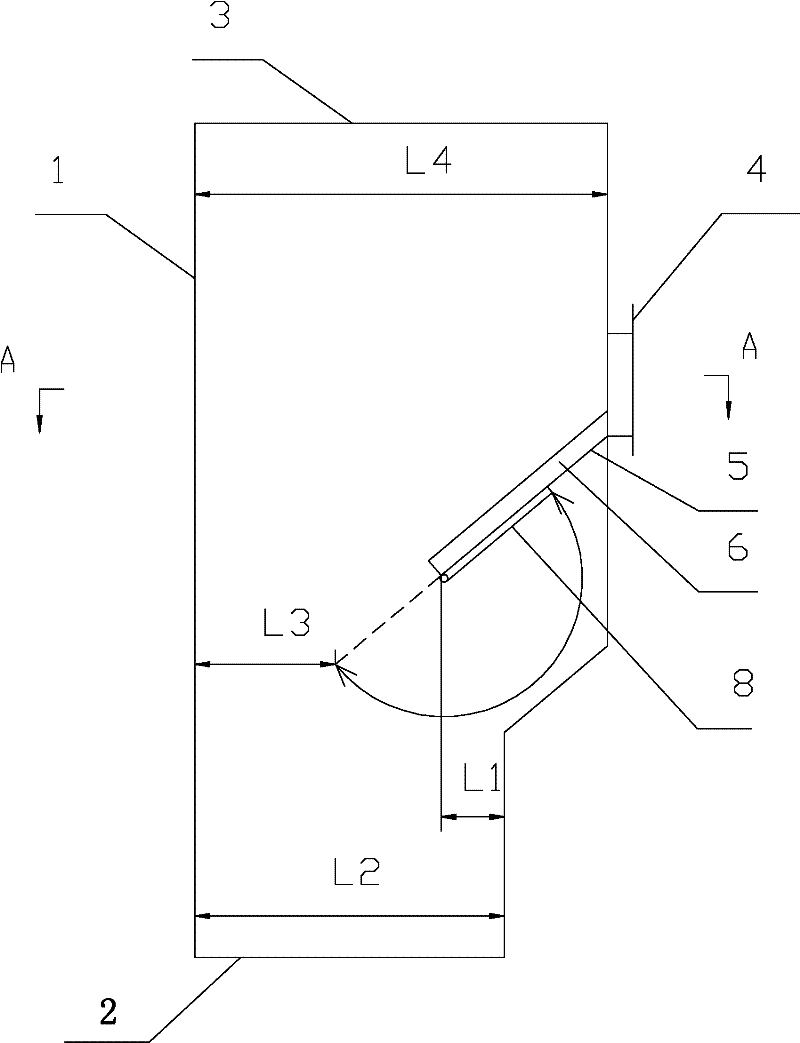

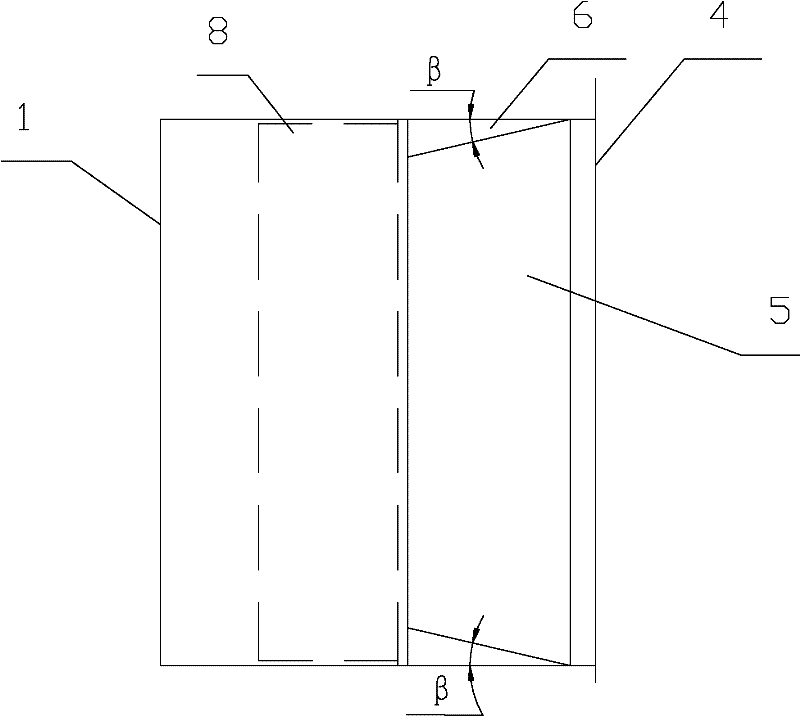

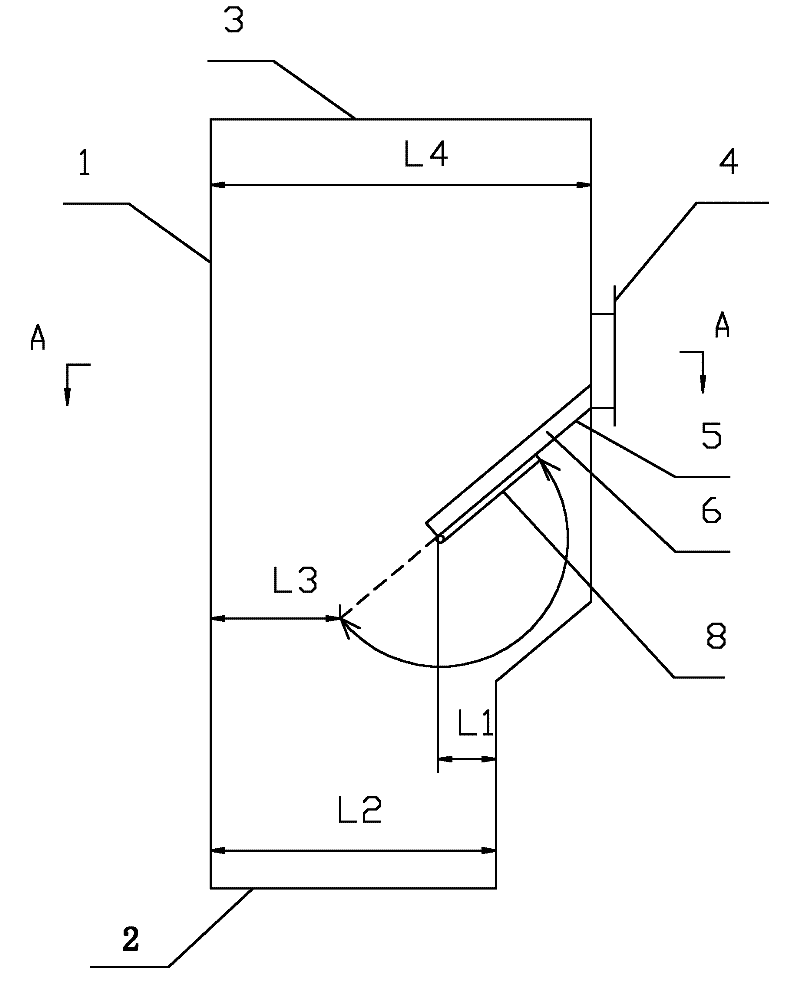

[0015] refer to figure 1 , figure 2 It is an embodiment of an ash gas mixing device used in a semi-dry desulfurization reactor of the present invention. A kind of ash gas mixing device used in a semi-dry desulfurization reactor includes an ash gas mixing section 1, and the ash gas mixing The lower port of the section 1 is the flue gas inlet 2, and the upper port of the ash gas mixing section 1 is the flue gas outlet 3, the cross-sectional area of the flue gas outlet 3 is larger than the cross-sectional area of the flue gas inlet 2, and the ash gas There is a mixed ash inlet 4 on the right side of the gas mixing section 1, and a downwardly inclined distribution plate 5 is arranged in the ash gas mixing section 1 below the mixed ash inlet 4, and the left side of the distribution plate 5 is connected with a Extended plate 8, said extended plate 8 is parallel to distribution plate 5 after said extension plate 8 is turned over, said distribution plate 5 is provided with ash r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com