Hydraulic lift-type maintenance car

A technology of hydraulic lifting and maintenance vehicles, which is applied in the direction of lifting devices, switchgears, electrical components, etc., which can solve problems such as unsafety, heavy weight of circuit breakers, and labor-intensive work, and achieve safe and reliable use, convenient work, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

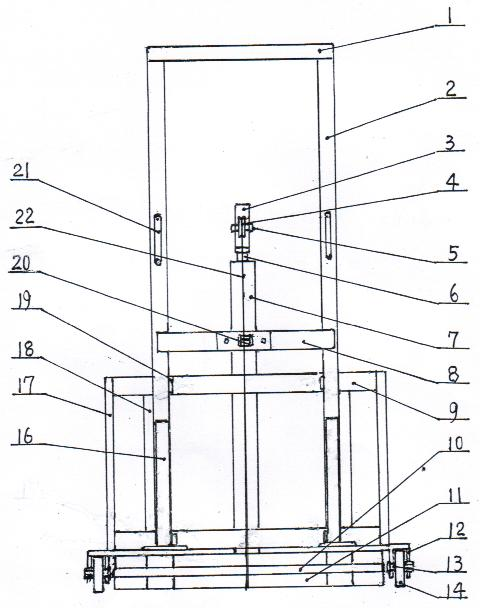

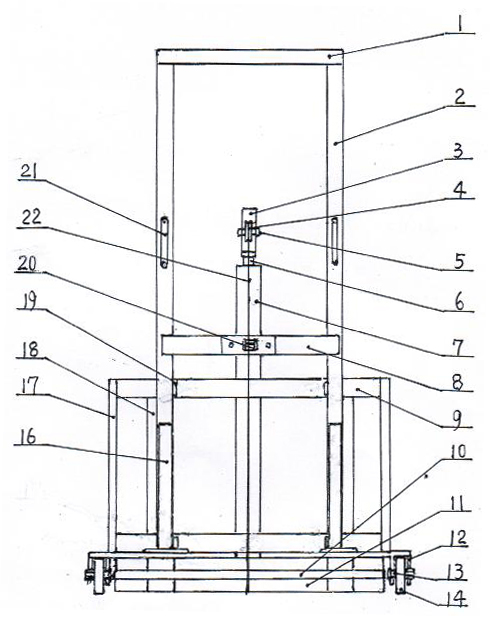

[0010] Examples, see attached figure 1 , 2 , the top of the main frame 2 of the hydraulic lifting maintenance vehicle is provided with an upper beam 1, the middle is provided with a middle beam 8, and the lower beam 11 connecting the supporting plate is set below the main frame 2. Mount the adjusting screw rod 10 on the lower cross frame 11 of the supporting plate, and one end of the adjusting screw rod 10 is provided with a crank handle 15 . The both sides of supporting plate lower beam 11 are fixed walking wheel axle frame 12, adorn walking wheel axle 13 on walking wheel axle frame 12, dress road wheel 14 on walking wheel axle 13. Two parallel guide frames 18 are established between the pallet horizontal frame 9 and the pallet lower horizontal frame 11 in the pallet vertical frames 17 on both sides, and two symmetrically parallel guide wheels 19 are installed up and down on the guide frame 18. Wheel 19 slides up and down in the guide groove on the main frame 2. A hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com