Double twisting machine

A two-for-one twister and frame technology, applied in textiles and papermaking, can solve problems affecting production efficiency and strand strength, and achieve the effects of improving efficiency, ensuring strength, and reducing the probability of production failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

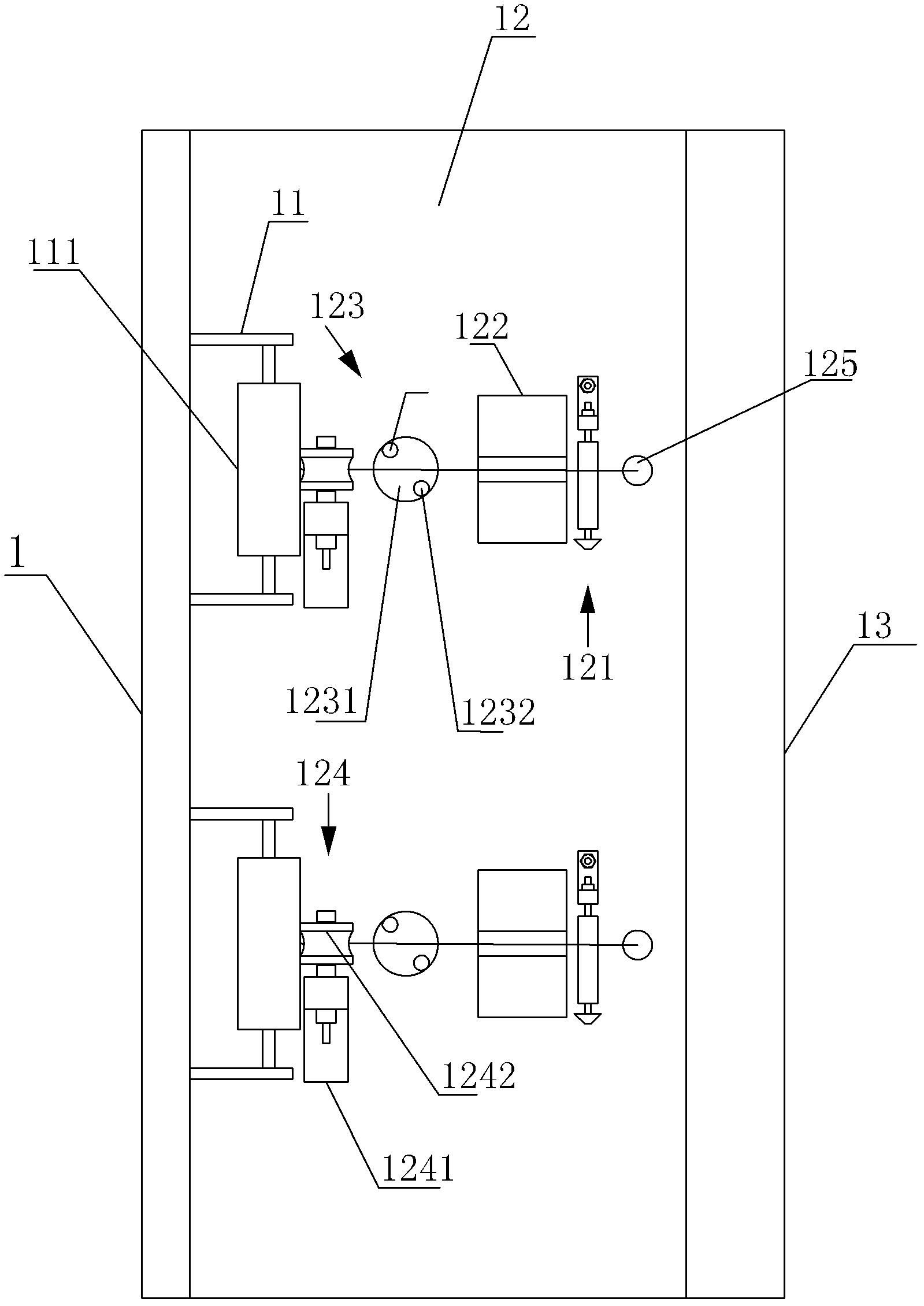

[0017] Such as figure 1 As shown, the two-for-one twister includes a frame 1, an upper mounting table 11, a middle mounting table 12, and a lower mounting table 13 arranged on the frame 1 from top to bottom.

[0018] The upper mounting table 11 is provided with a plurality of winding devices 111; the lower mounting table 13 is provided with the same number of wire storage drums 131 as the number of winding devices 11, the wire storage drums 131 are upstream, and the winding device 111 is downstream .

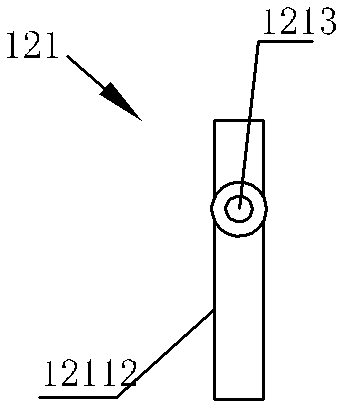

[0019] The middle installation platform 12 is provided with an electronic eye 122 for detecting the state of the single wire, and a transition device 121 arranged between the electronic eye 122 and the wire storage barrel 131 for preventing the single wire from being scraped off. It is arranged on the middle installation platform 12 and The gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com